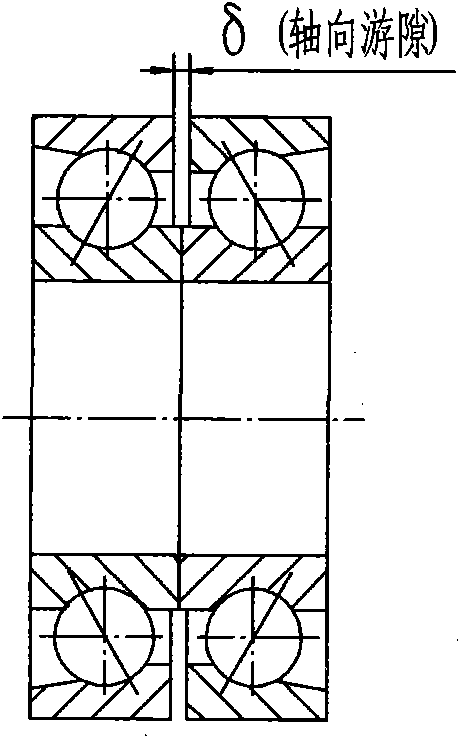

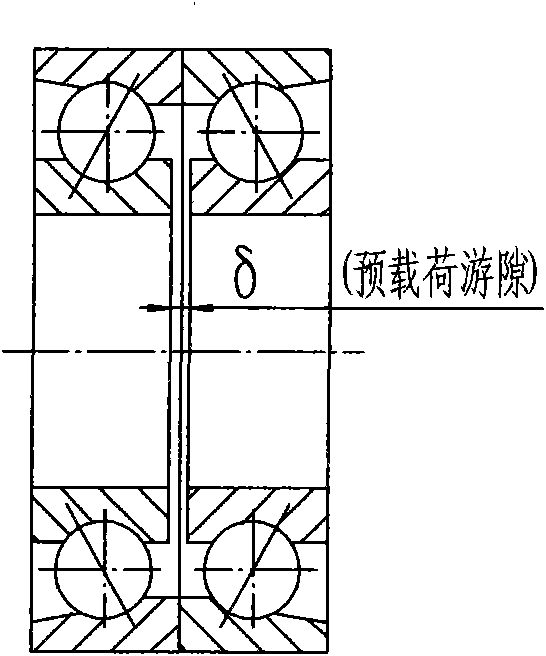

Method for measuring axial clearance and preload clearance of back-to-back angular contact ball bearings

A technology of angular contact ball bearings and axial clearance, applied in the direction of mechanical clearance measurement, etc., can solve the problems of cumulative error, complex operation procedures, cumbersome efficiency, etc., to achieve guaranteed accuracy, simple operation, A value and B value can be intuitive The effect of reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

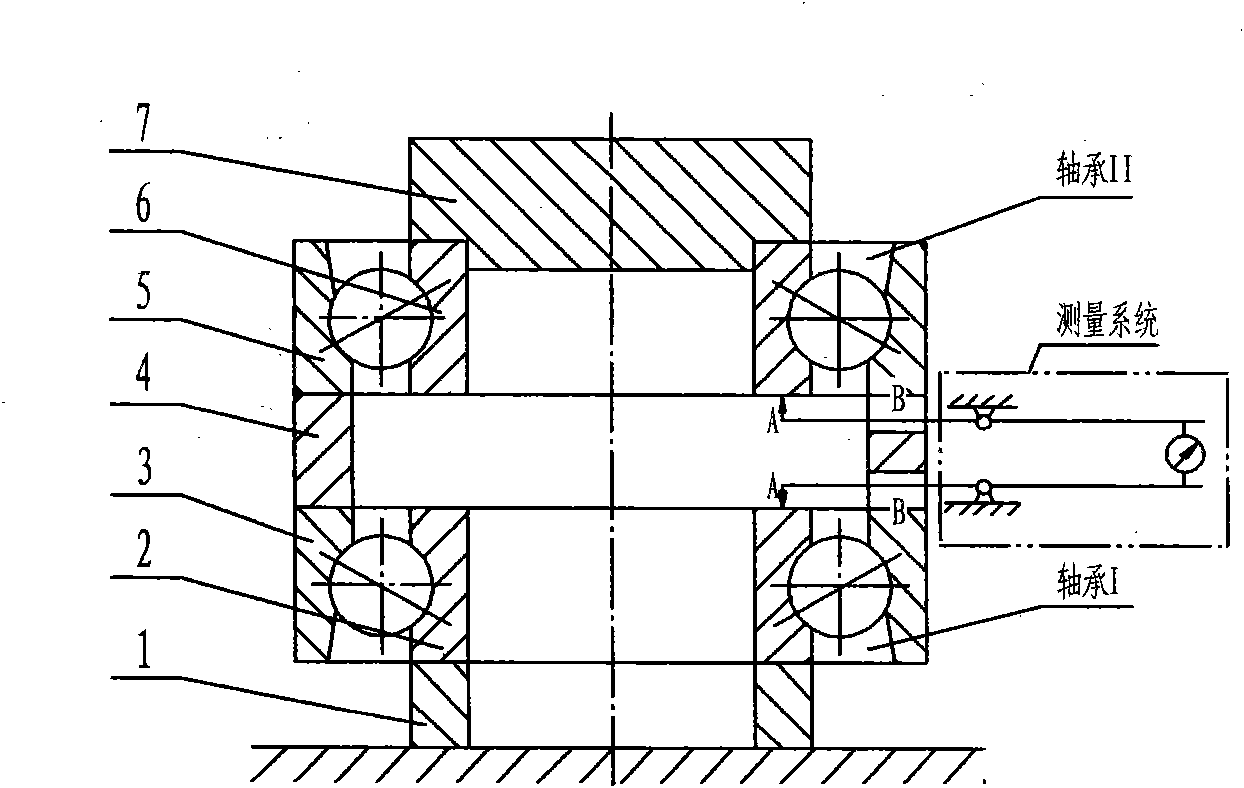

[0020] combine image 3 , the present invention will make outer ring spacer 4, washer 1, inner diameter load block 7 and a measuring system earlier before measuring.

[0021] The inner diameter of the outer ring spacer 4 is equal to the inner diameter of the outer ring of the bearing I or bearing II, and the outer diameter of the outer ring spacer 4 is equal to the outer diameter of the outer ring of the bearing I or bearing II, and the radial opening of the outer ring spacer 4 There are two symmetrical notch slots. The outer ring spacer 4 must undergo heat treatment, and the hardness after heat treatment can reach HRC60-65. Secondly, the outer ring spacer 4 needs to be precisely ground to ensure that the parallel difference between the two ends of the outer ring spacer 4 is not greater than 1 μm. Finally, the outer ring spacer The notch of sleeve 4 should be able to pass through the two parallel right-angle probes in the measuring system smoothly.

[0022] The outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com