Composite catalyst flue gas denitrating under low-temperature condition and method of preparing the same

A composite catalyst, low temperature technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of poor thermal stability, low activity, etc., and achieve cost Low, low element cost, longevity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

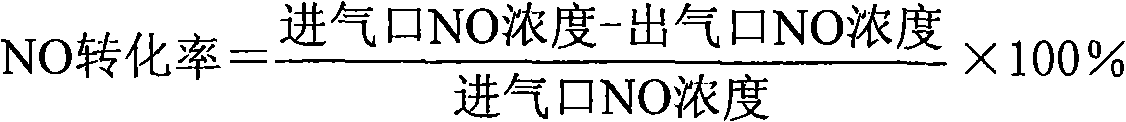

Method used

Image

Examples

Embodiment 1

[0026] Weigh 133.5g of ZrO(NO 3 ) 2 2H 2 O and 92.96g of TiCl 4 , first ZrO(NO 3 ) 2 2H 2 O was dissolved in 1 L of deionized water, and the TiCl 4 Drop into the zirconyl nitrate solution and continue stirring until completely dissolved. Under vigorous stirring, the mixed solution obtained above was slowly dripped into the ammonia solution to pH=8, and a large amount of white precipitate was rapidly generated, aged for 2 hours, the excess liquid in the upper layer was filtered off, and the white precipitate was washed until there was no chloride ion (with nitric acid Silver solution test), pumping rate to obtain precipitated matter, dried in an oven at 110°C and calcined at 500°C for 6h to obtain a catalyst carrier. Immerse the equal volume of the obtained carrier in the solution of manganese acetate and cerium nitrate, after immersion for 4 hours, dry it directly in an oven at 110°C, and then calcinate at 600°C for 2 hours to obtain a catalyst, in which manganese oxide...

Embodiment 2

[0030] Weigh 132.6g of ZrOCl 2 ·8H 2 O and 117.62 g of TiCl 4 , first ZrOCl 2 ·8H 2 O was dissolved in 1 L of deionized water, and the TiCl 4 Drop into the zirconium oxychloride solution and continue stirring until completely dissolved. Under vigorous stirring, the mixed solution obtained above is slowly dripped into the ammonium carbonate solution until the pH is 9, a large amount of white precipitates are rapidly generated, aged for 2h, the excess liquid in the upper layer is filtered, and the white precipitates are washed until there is no chloride ion (with Silver nitrate test), pumping rate to obtain precipitated matter, dried in an oven at 110°C, and calcined at 550°C for 2h to obtain a catalyst carrier. Immerse the equal volume of the obtained carrier in a solution of manganese nitrate and ammonium metavanadate, let it stand for 4 hours, dry it in an oven at 110°C, and calcinate it at 450°C for 2 hours to obtain a catalyst, in which manganese oxides account for tit...

Embodiment 3

[0034] Weigh 132.61g of ZrCl 4 and 74.05g of TiOSO 4 2H 2 O, first ZrCl 4 Dissolved in 1L of deionized water, then TiOSO 4 2H 2O was dropped into the zirconium chloride solution and continued to stir until it was completely dissolved. Under vigorous stirring, slowly drop the mixed solution obtained above into the ammonia solution to pH = 10, a large amount of white precipitate is rapidly formed, age for 2 hours, filter off the excess liquid in the upper layer, wash the white precipitate 6 times, and pump the precipitate to obtain the precipitate The material was dried in an oven at 110°C, and calcined at 600°C for 2 hours to obtain a catalyst carrier. Immerse the equal volume of the obtained carrier in the solution of manganese nitrate and ferric nitrate, dry it in an oven at 110°C after immersion for 4 hours, and calcinate it at 350°C for 2 hours to obtain the catalyst, in which the oxide of manganese accounts for 1% of the mass of the titanium-zirconium composite oxide....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com