X type zeolite molecular sieve and method for producing the same

A zeolite molecular sieve and molecular sieve technology are applied in the direction of molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., which can solve problems such as difficult recovery, and achieve the solution of difficult recovery, strong magnetism and magnetic stability, Good effect of crystal shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

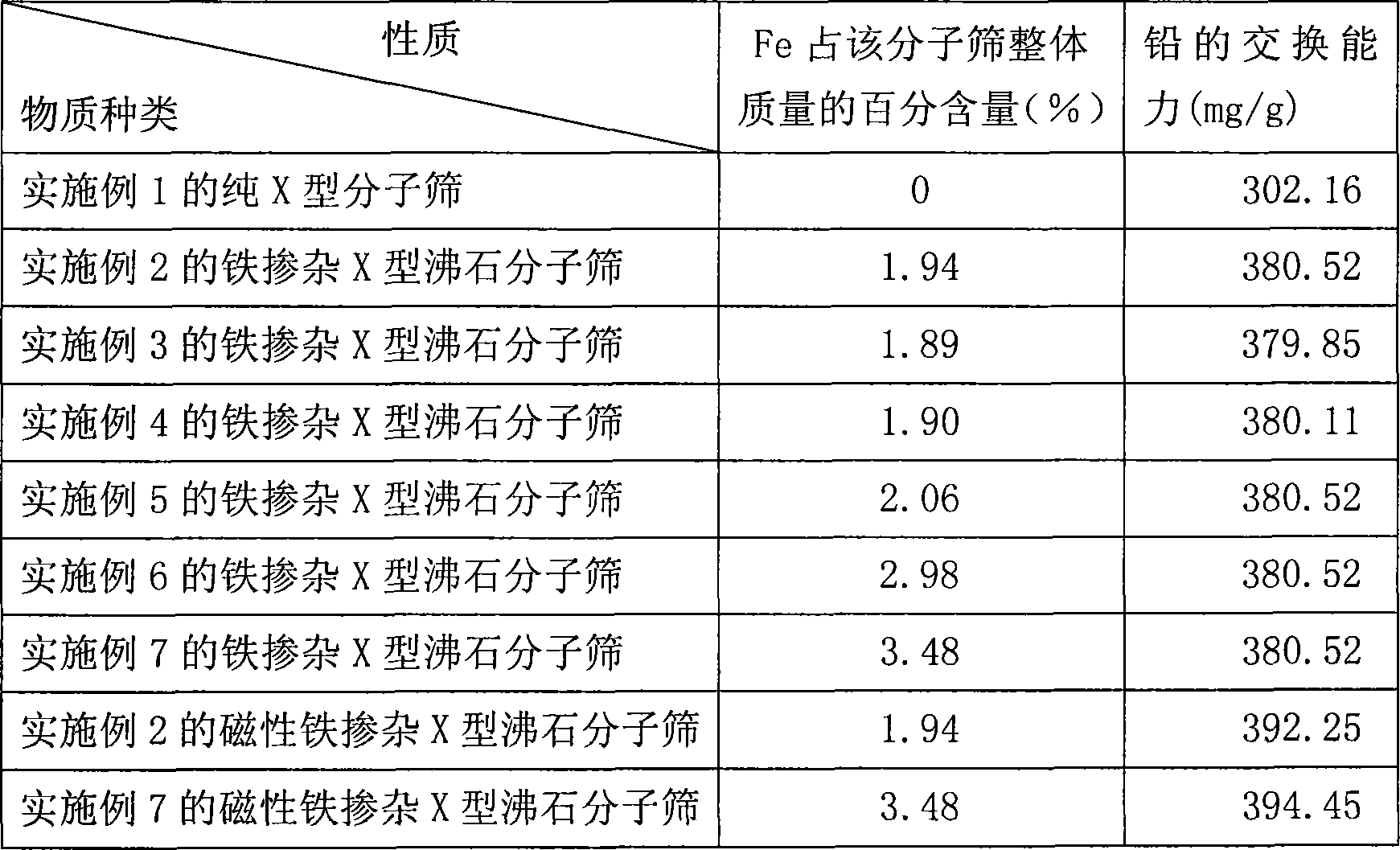

[0027] This example is a comparative example, and a pure X-type zeolite molecular sieve was synthesized under hydrothermal pressure.

[0028] Weigh 23g Na respectively 2 SiO 3 9H 2 O, 11.2g NaAlO 3 , 15.5g NaOH and 10.8g KOH, with 92ml deionized water to configure a molar ratio of 3.5Na 2 O:K 2 O:0.7Al 2 o 3 : 0.9SiO2 2 : 62H 2 The starting material of O was put into a 500ml three-neck flask, aged and stirred at 70°C for 3 hours, then crystallized at 95°C for 2 hours, separated by filtration to obtain a crystalline solid phase substance, and washed with deionized water to medium properties, and finally dry the crystalline solid-phase substance at a temperature of 115°C to obtain X-type zeolite molecular sieves.

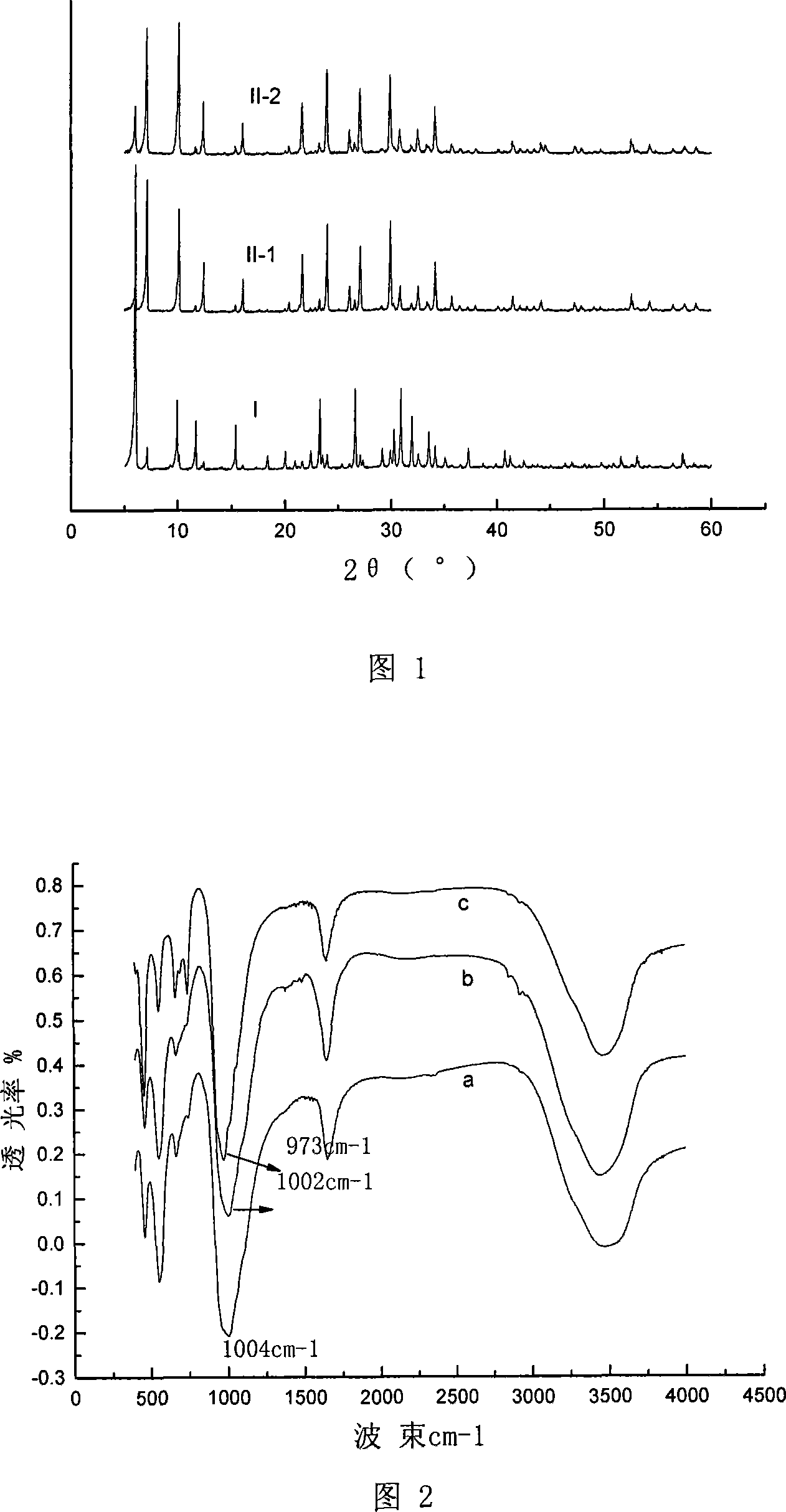

[0029] Curve I in Fig. 1 is the X-ray diffraction spectrum of the pure X-type zeolite molecular sieve synthesized in this embodiment, which is consistent with the X-ray diffraction spectrum of the standard pure X-type zeolite molecular sieve. Curve a in Figu...

Embodiment 2

[0031] The first step, the synthesis of iron-doped X-type zeolite molecular sieve

[0032] Take 2g H 2 C 2 o 4 , 0.5g Fe(NO 3 ) 3 Dissolved in 30ml deionized water to prepare a buffer solution of ferric oxalate , take 23g Na 2 SiO 3 9H 2Dissolve O in 50ml of water to form a sodium silicate solution, dissolve 11.2g of sodium aluminate in 40ml of water to form a sodium aluminate solution, dissolve 15.5g of sodium hydroxide and 10.8g of potassium hydroxide in 32ml of water to form two A mixed solution of alkali and alkali, slowly add solution to solution , while stirring, then dropwise add solution and solution mixed solution, while stirring, put the evenly stirred mixture into a three-necked bottle Inside, aged and stirred at a temperature of 70°C for 3 hours, then crystallized at a temperature of 95°C for 2 hours, separated by filtration to obtain a crystalline solid-phase substance, and washed the crystalline solid-phase substance with deionized water to neutr...

Embodiment 3

[0038] The first step, the synthesis of iron-doped X-type zeolite molecular sieve

[0039] Take 0.5g H 2 C 2 o 4 , 0.5g Fe(NO 3 ) 3 Dissolved in 30ml deionized water to prepare a buffer solution of ferric oxalate , take 23g Na 2 SiO 3 9H 2 Dissolve O in 50ml of water to form a sodium silicate solution, dissolve 11.2g of sodium aluminate in 40ml of water to form a sodium aluminate solution, dissolve 15.5g of sodium hydroxide and 10.8g of potassium hydroxide in 32ml of water to form two A mixed solution of alkali and alkali, slowly add solution to solution , while stirring, then dropwise add solution and solution mixed solution, while stirring, put the evenly stirred mixture into a three-necked bottle Inside, aged and stirred at a temperature of 70°C for 3 hours, then crystallized at a temperature of 95°C for 2 hours, separated by filtration to obtain a crystalline solid-phase substance, and washed the crystalline solid-phase substance with deionized water to ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com