Granular titanium-silicon molecular sieve catalyst and preparation method thereof

A titanium-silicon molecular sieve and catalyst technology, applied in molecular sieve catalysts, catalyst activation/preparation, chemical instruments and methods, etc., can solve the problems of difficult separation, easy breakage, low strength, etc., and achieve easy separation, difficult to crush, and large particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a granular titanium-silicon molecular sieve catalyst, comprising the following steps:

[0032] (1) According to the mass ratio of 1:1:0.5:0.5:1: titanium silicon molecular sieve (TS-1) fine powder, tetraethyl silicate (TEOS), ethylene glycol-propylene glycol-ethylene glycol copolymer Compound (P123, average molecular weight 5800), mass percent concentration are 36% hydrochloric acid and water;

[0033] (2) Add hydrochloric acid into water, add P123 under stirring, after P123 dissolves, add TEOS dropwise, after TEOS is completely hydrolyzed (from milky to transparent), add TS-1 fine powder and mix to form a slurry;

[0034] (3) Calcining the slurry in air at 550° C. for 30 hours to obtain a granular titanium-silicon molecular sieve catalyst.

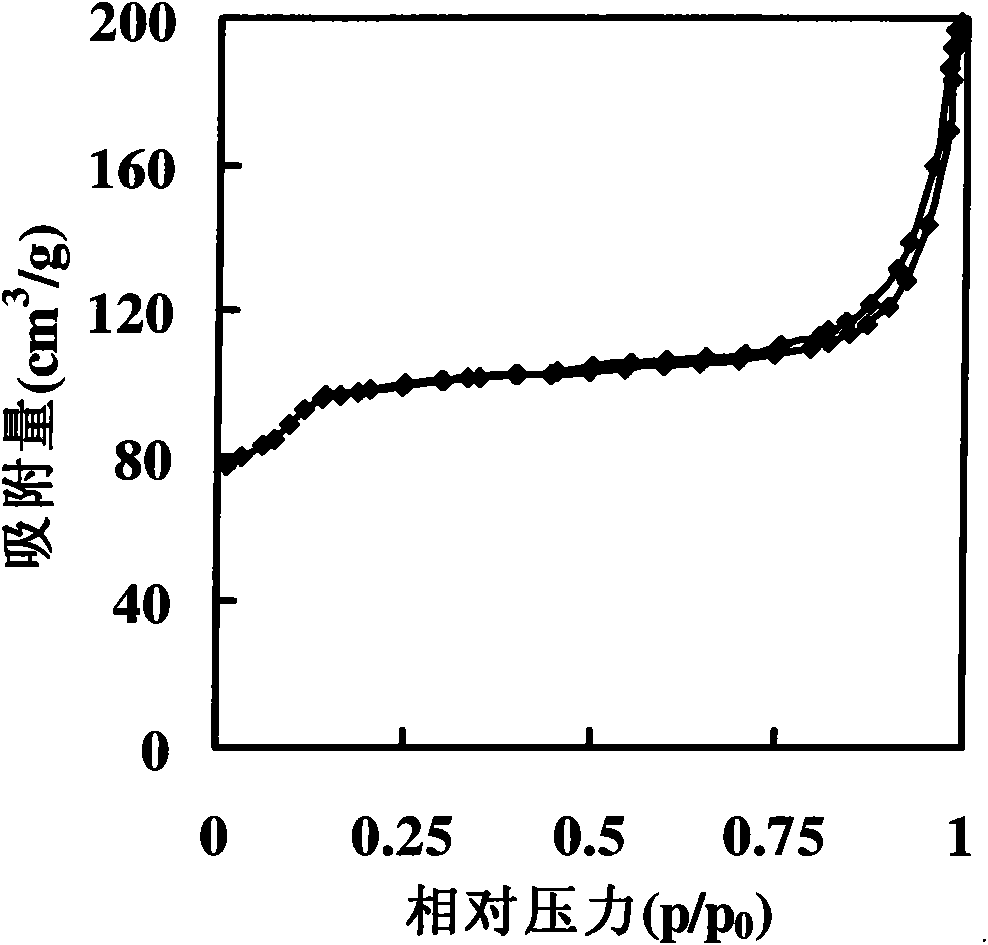

[0035] The particle diameter of the granular titanium-silicon molecular sieve catalyst is 5 μm to 75 μm. Nitrogen physical adsorption and desorption isotherms (see figure 1 ) shows a hysteresis loop, which...

Embodiment 2

[0037] The granular titanium-silicon molecular sieve catalyst prepared by Example 1 is used to catalyze the epoxidation reaction of propylene, and the experimental steps are as follows: the reaction is carried out at 120 cm 3 in a high-pressure reactor. Water bath heating, magnetic stirring, the reaction kettle is equipped with a water cooling device. Add 32cm to the reactor 3 Methanol, the granular titanium silicon molecular sieve catalyst that 0.40g prepares with embodiment 1, the hydrogen peroxide (H of 3.60g (30wt.%) 2 o 2 ) and 1.30 g of methyl tert-butyl ether (MTBE), heated to 40° C. in a water bath, passed through propylene to maintain the reaction pressure at 0.4 MPa, and the stirring speed was 1000 rpm, and the reaction was carried out for 1.5 h.

[0038] After the reaction, the product is separated from the catalyst with a centrifuge, analyzed by HP4890 gas chromatography, the FID detector, the chromatographic column is SE-54 (30m × 0.25mm × 0.33 μm), and the met...

Embodiment 3

[0044] A method for preparing a granular titanium-silicon molecular sieve catalyst, comprising the following steps:

[0045] (1) According to the mass ratio of 1:1:1.4:0.2:1: TS-1 fine powder, TEOS, P123 (average molecular weight 5800), hydrochloric acid and water with a mass percentage concentration of 36%;

[0046] (2) Add hydrochloric acid into water, add P123 under stirring, after P123 dissolves, add TEOS dropwise, after TEOS is completely hydrolyzed (from milky to transparent), add TS-1 fine powder and mix to form a slurry;

[0047](3) Calcining the slurry in air at 500° C. for 30 hours to obtain a granular titanium-silicon molecular sieve catalyst.

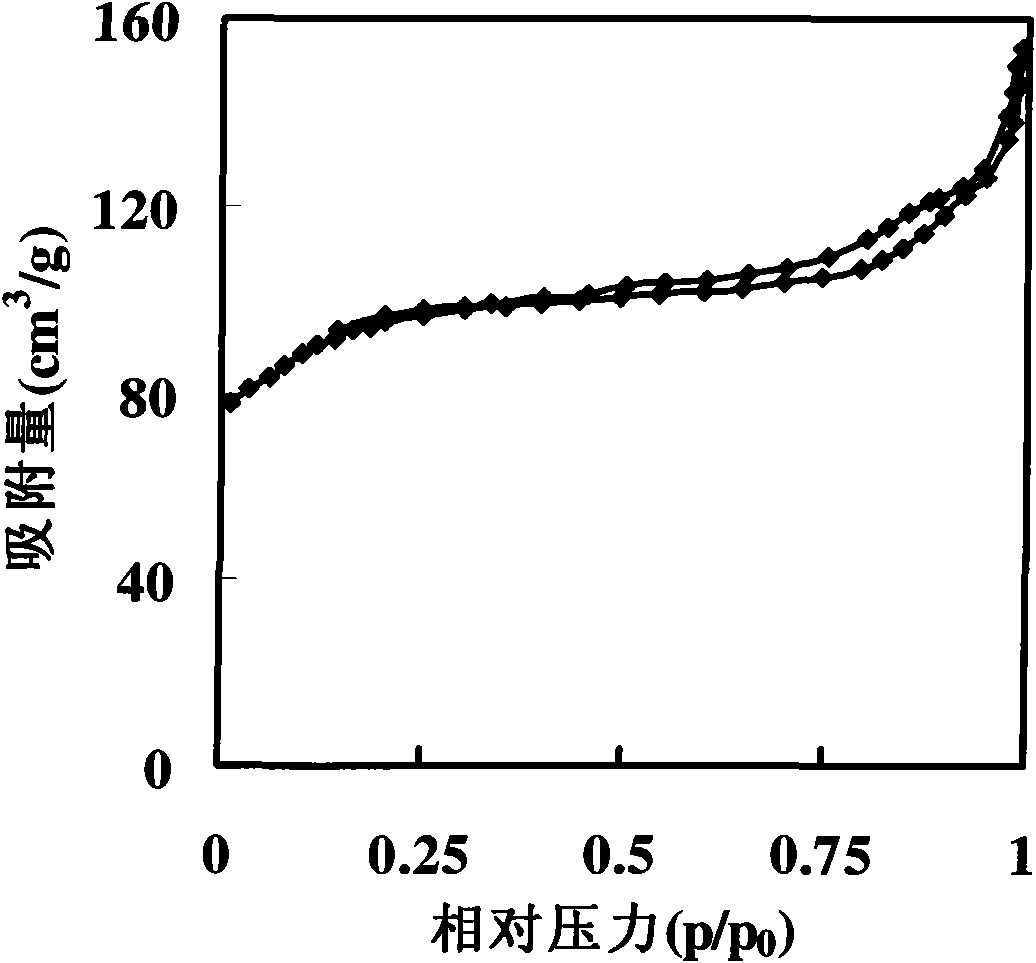

[0048] The particle diameter of the granular titanium-silicon molecular sieve catalyst is 5 μm to 70 μm. Nitrogen physical adsorption and desorption isotherms (see image 3 ) shows a hysteresis ring, indicating that the silica gel except TS-1 fine powder exists in the form of mesopores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com