Molecular sieve packaged noble metal catalyst as well as preparation method and application thereof

A precious metal catalyst, precious metal technology, applied in molecular sieve catalysts, including molecular sieve catalysts, catalysts, etc., can solve problems such as affecting the catalytic performance of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a molecular sieve-encapsulated noble metal catalyst, comprising the following steps:

[0032] (1) heating and mixing the noble metal precursor with polyvinyl alcohol and water to obtain a premixed solution; the noble metal is one or more of Pd, Pt, Ru and Rh, and the noble metal precursor is a chloride of a noble metal, One or more of noble metal chloramines, noble metal nitrates, noble metal acetates and noble metal hydrochloric acid;

[0033] (2) NaBH 4 Mixing with the premixed solution, performing a reduction reaction to obtain a precious metal sol dispersion;

[0034] (3) mixing the molecular sieve with the precious metal sol dispersion, and performing the first drying and the first roasting on the obtained solid after the solid-liquid separation to obtain the molecular sieve with the precious metal loaded on the surface;

[0035] (4) Mix the molecular sieve loaded with the precious metal on the surface with the organi...

Embodiment 1

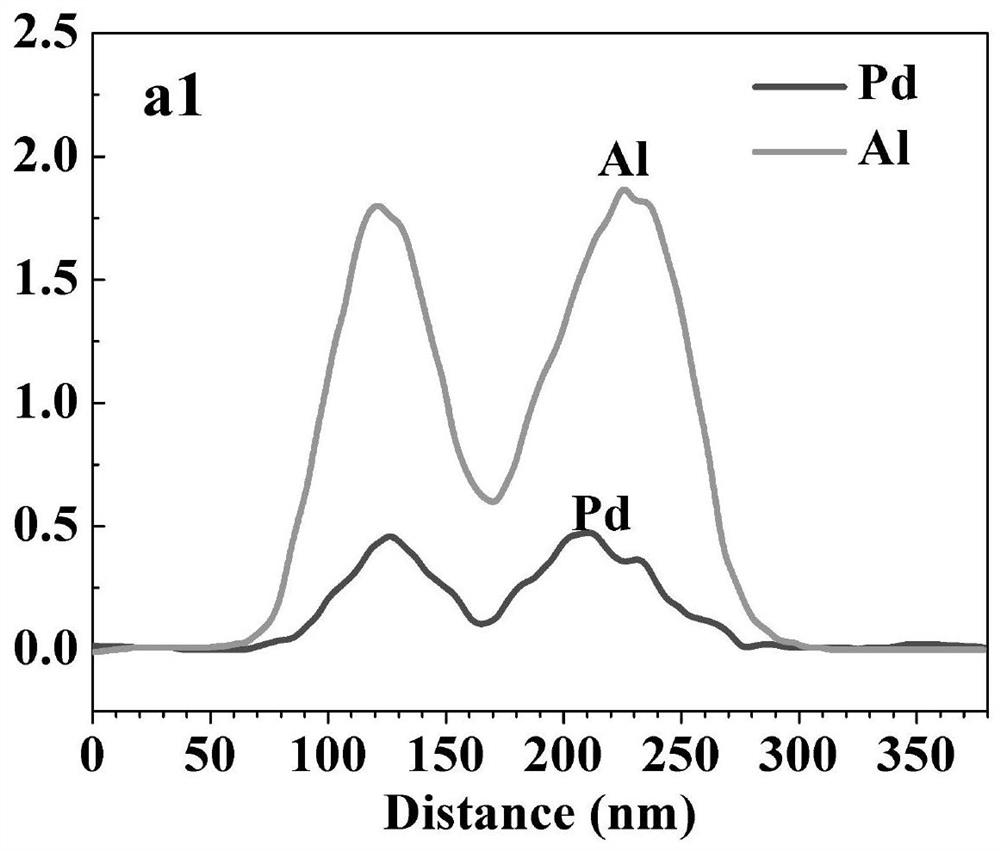

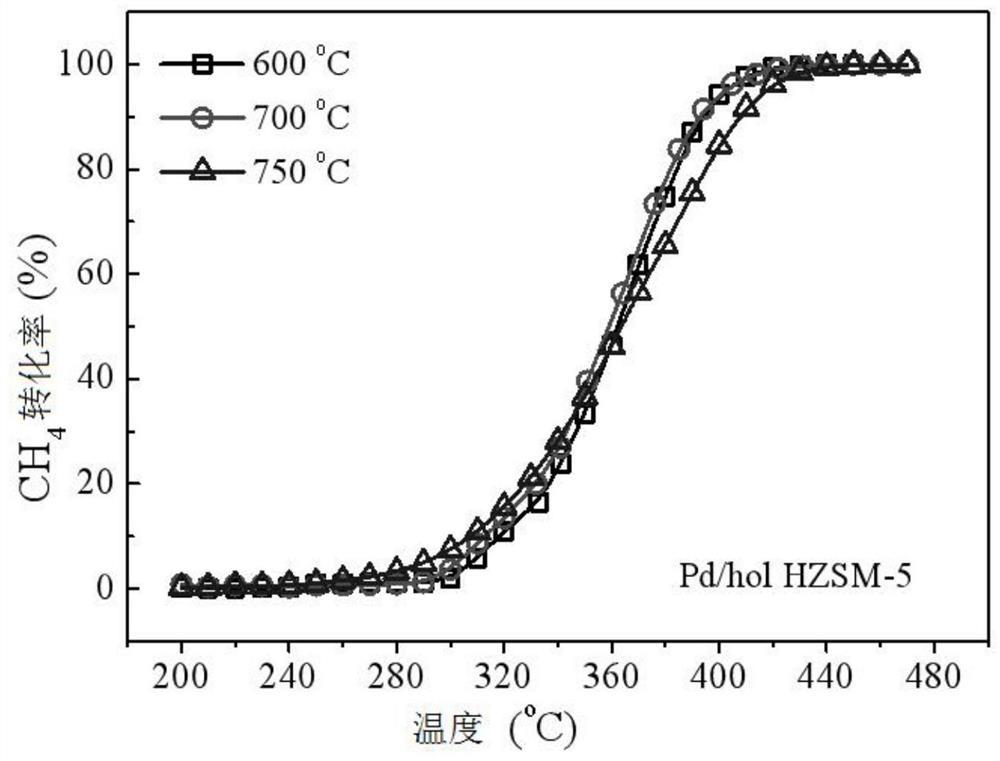

[0055] (1) Take 0.167g of palladium chloride, add it into 8g of water, stir evenly, add 0.4g of PVA, stir evenly, heat to 80°C for 10 minutes to peptize. Then 0.1mol / L NaBH 4 Aqueous solution (NaBH 4 The molar ratio to Pd is 5:1) was quickly added to the above solution to obtain a PVA-stabilized Pd sol; after vigorous stirring for 30 min, it was ready for use.

[0056] (2) Add 10 g of molecular sieve molecular sieve carriers with a grain size of 500 nm and a silicon-aluminum ratio of 30 to (1), continue stirring for 3 hours until the color of the solution fades, and finally centrifuge and wash until no Cl is detected. ﹣ Finally, the sample was dried in an oven at 100°C for 5h, and then calcined at 500°C for 5h in the air atmosphere of a muffle furnace to obtain a molecular sieve with a Pd content of 1wt% on the surface of a noble metal, which was designated as Pd / H-ZSM-5. use.

[0057] (3) Disperse the surface-loaded noble metal molecular sieve prepared in (2) in 0.1mol / L T...

Embodiment 2

[0062] (1) Take 0.133g of chloroplatinic acid, add it into 8g of water, stir evenly, add 0.4g of PVA, stir evenly, heat to 80°C for 10 minutes to peptize. Then 0.1mol / L NaBH 4 An aqueous solution (the molar ratio of NaBH4 to Pd is 4:1) was quickly added to the above solution to obtain a PVA-stabilized Pd sol; after vigorous stirring for 30 min, it was ready for use.

[0063] (2) Add 10 g of Silicalite-1 molecular sieve carrier with a grain size of 400 nm to (1), continue to stir for 3 hours until the color of the solution fades, and finally centrifuge and wash until no Cl is detected. ﹣ Finally, the sample was dried in an oven at 100°C for 5h, and then calcined at 500°C for 5h in the air atmosphere of a muffle furnace to obtain a Pd / H-ZSM-5 catalyst with a Pt content of 0.5%.

[0064] (3) Disperse the catalyst prepared in (2) in 0.1mol / L TPAOH solution (1g catalyst corresponds to 10mL TPAOH solution), stir at room temperature for 30min, then transfer it to the reaction kettle, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com