A kind of high porosity and high permeability nb2o5 ceramic membrane and preparation method thereof

A high-permeability, high-porosity technology, used in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problem of catalyst incompatibility, catalytic conversion efficiency, narrow pore size distribution, high permeability, and wide pore size distribution. and other problems, to achieve the effect of improving membrane treatment effect, easy control of pore structure and pore size, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

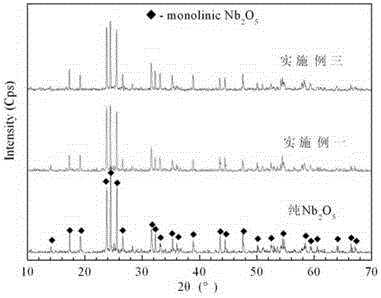

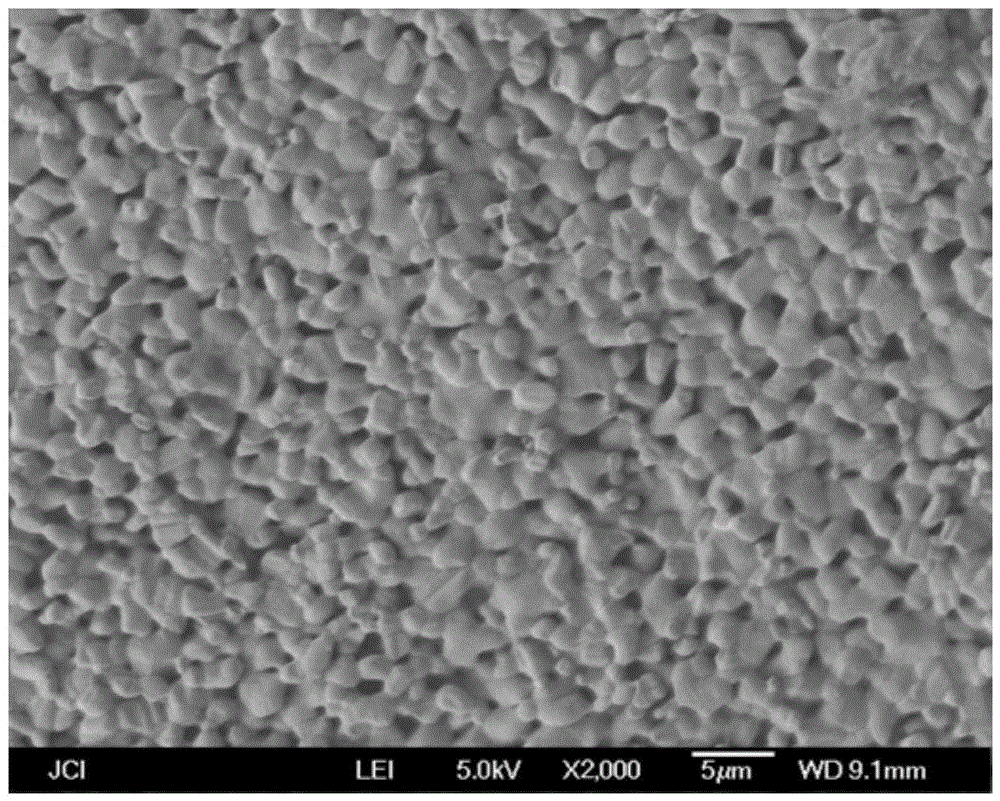

Embodiment 1

[0040] 1. A kind of high porosity and high permeability Nb in this embodiment 2 o 5 The ceramic membrane is composed of a support body and a separation membrane layer. Ta of support body and separation membrane layer 2 o 5 and TiO 2 The contents are respectively 15mol% and 4mol%, that is, the general formula is Nb 1.62 Ta 0.3 Ti 0.04 o 5-δ .

[0041] 2. The above-mentioned high porosity and high permeability Nb in this embodiment 2 o 5 The preparation method of ceramic film, its step is as follows:

[0042] (1) Preparation of support body

[0043] (1-1) with Nb 2 o 5 Powder, Ta 2 o 5 Powder and TiO 2 powder as raw material, where Nb 2 o 5 The particle size of powder is 1~100μm, Ta 2 o 5 Powder particle size ≤ 1μm, TiO 2 The particle size of the powder is less than or equal to 0.3 μm; batching is carried out according to the above-mentioned general formula of the support body, and then the yttrium oxide stabilized zirconia ball (TZP ball) is used as the gri...

Embodiment 2

[0053] 1. A kind of high porosity and high permeability Nb in this embodiment 2 o 5 Ceramic membrane, its composition is the same as embodiment one.

[0054] 2. The above-mentioned high porosity and high permeability Nb in this embodiment 2 o 5 The preparation method of ceramic film, its step is as follows:

[0055] (1) Preparation of support body

[0056] (1-1) The preparation of the support body mixed powder is the same as in Example 1;

[0057] (1-2) The support body adopts extrusion molding method, and the composition of its green body is as follows: support body mixed powder 70wt%, hydroxypropyl cellulose 6wt%, glycerin 2wt%, oleic acid 2wt%, water 20wt%, mix After homogeneity, the mud is vacuum smelted, and it is placed in an airtight container to stale for more than 24 hours for later use; it is extruded by an extrusion molding machine to obtain 19-channel Nb 2 o 5 The ceramic membrane support body was wet, dried at room temperature for 24 hours, and then dried a...

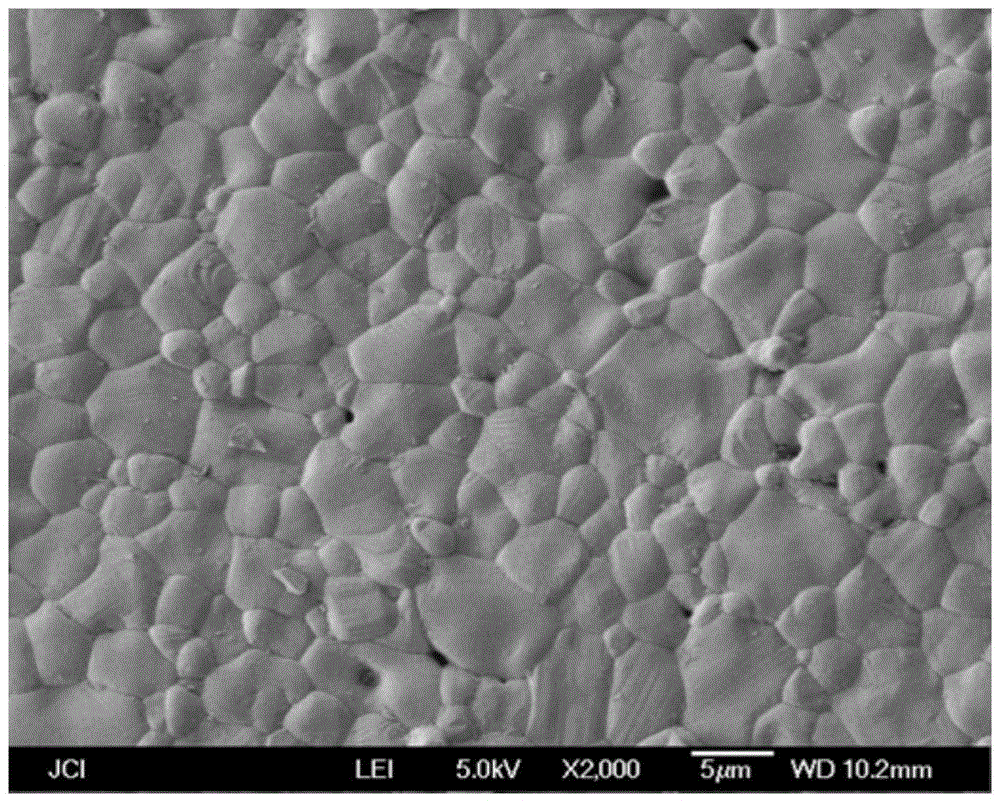

Embodiment 3

[0066] 1. A kind of high porosity and high permeability Nb in this embodiment 2 o 5 The ceramic membrane is composed of a support body and a separation membrane layer. Ta of support body and separation membrane layer 2 o 5 and TiO 2 The contents are respectively 25mol% and 6mol%, that is, the general formula is Nb 1.38 Ta 0.5 Ti 0.06 o 5-δ .

[0067] 2. The above-mentioned high porosity and high permeability Nb in this embodiment 2 o 5 The preparation method of ceramic film, its step is as follows:

[0068] (1) Preparation of support body

[0069] (1-1) with Nb 2 o 5 Powder, Ta 2 o 5 Powder and TiO 2 powder as raw material, where Nb 2 o 5 The particle size of powder is 1~100μm, Ta 2 o 5 Powder particle size ≤ 1μm, TiO 2 The particle size of the powder is less than or equal to 0.3 μm; batching is carried out according to the above-mentioned general formula of the support body, and then the yttrium oxide stabilized zirconia ball (TZP ball) is used as the gri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com