Preparation method of graphene-based iridium copper nano composite material

A composite material, alkenyl iridium technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of large difference in carbon powder morphology, low catalyst uniformity and dispersion, and grinding degree. Limitation and other problems, to achieve the effect of increasing the number of active sites, increasing the number of electrocatalytic active sites, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step 1, the IrCl 3 and CuCl 2 Dissolve in deionized water to obtain a mixed solution; in the mixed solution, IrCl 3 and CuCl 2 The total concentration of is 1g / L, and the element molar ratio of iridium and copper is 1:1;

[0030] Step 2, adding graphene oxide powder to the mixed solution prepared in step 1, and then ultrasonically dispersing for 1 h to obtain a suspension; the quality of the graphene oxide powder is 1 times the metal equivalent in the mixed solution;

[0031] Step 3, sending the suspension obtained in step 2 into a spray dryer at a feeding rate of 50mL / h, and performing atomization and drying at 120° C. to obtain a powder of graphene oxide-loaded mixed metal salt;

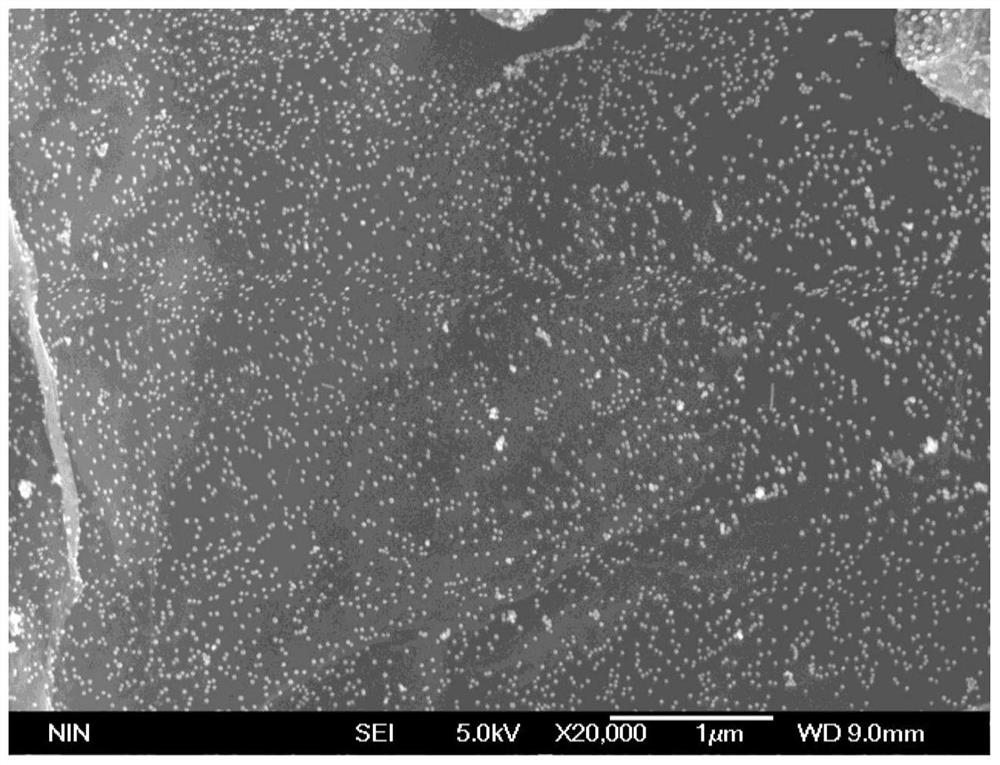

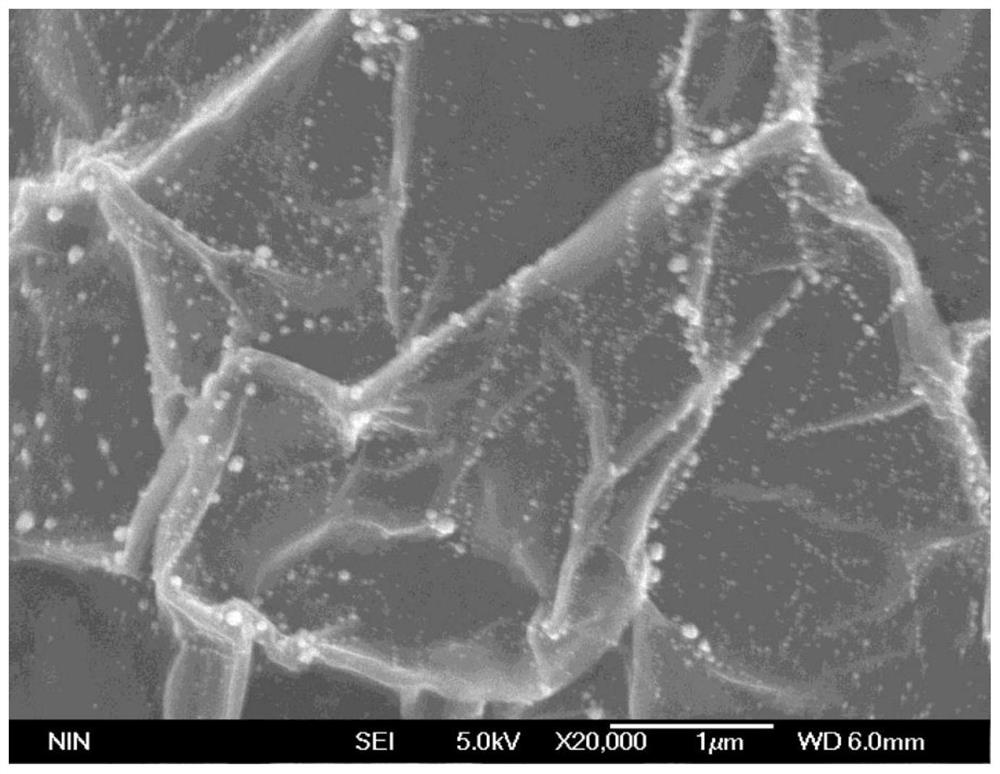

[0032] Step 4, placing the powder of the graphene oxide loaded mixed metal salt obtained in step 3 in a tube furnace for synchronous thermal reduction treatment to obtain graphene-based iridium-copper nanocomposites; the process of t...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step 1, the IrCl 3 and CuCl 2 Dissolve in deionized water to obtain a mixed solution; in the mixed solution, IrCl 3 and CuCl 2 The total concentration of is 5g / L, and the element molar ratio of iridium and copper is 1:1;

[0038] Step 2, adding graphene oxide powder to the mixed solution prepared in step 1, and then ultrasonically dispersing for 1 h to obtain a suspension; the quality of the graphene oxide powder is 1 times the metal equivalent in the mixed solution;

[0039]Step 3, sending the suspension obtained in step 2 into a spray dryer at a feed rate of 200mL / h, and performing atomization and drying at 250° C. to obtain a powder of graphene oxide-loaded mixed metal salt;

[0040] Step 4, placing the powder of the graphene oxide loaded mixed metal salt obtained in step 3 in a tube furnace for synchronous thermal reduction treatment to obtain graphene-based iridium-copper nanocomposites; the process of the ...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] Step 1, the IrCl 3 and CuCl 2 Dissolve in deionized water to obtain a mixed solution; in the mixed solution, IrCl 3 and CuCl 2 The total concentration of is 0.5g / L, and the element molar ratio of iridium and copper is 1:4;

[0046] Step 2, adding graphene oxide powder to the mixed solution prepared in step 1, and then ultrasonically dispersing for 1 h to obtain a suspension; the quality of the graphene oxide powder is 2 times the metal equivalent in the mixed solution;

[0047] Step 3, sending the suspension obtained in step 2 into a spray dryer at a feed rate of 100mL / h, and performing atomization and drying at 150° C. to obtain a powder of graphene oxide-loaded mixed metal salt;

[0048] Step 4, placing the powder of the graphene oxide loaded mixed metal salt obtained in step 3 in a tube furnace for synchronous thermal reduction treatment to obtain graphene-based iridium-copper nanocomposites; the process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com