Polyether polyol used for polyurethane single-component grouting materials and preparation method and application thereof

A technology of polyether polyol and grouting material, which is applied in the field of polyether polyol for polyurethane and its production method, and can solve problems such as high energy consumption, high melting point, and difficult reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

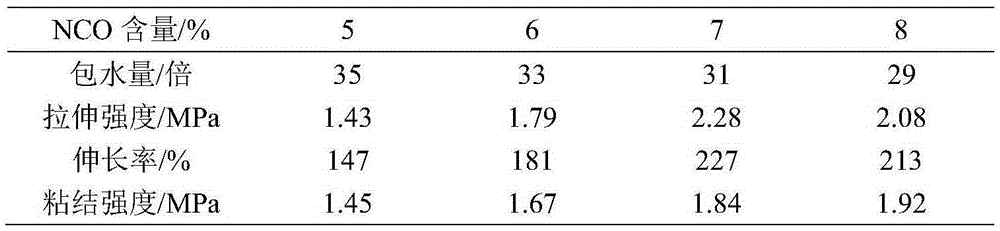

Examples

Embodiment 1

[0025] Add 15.4g of glycerin, 11.6g of sorbitol, and 4.5g of KOH into the polymerization reactor. After nitrogen replacement for 3 times, start vacuuming to -0.98MPa, then raise the temperature to 120°C and start dehydration for 2 hours. When the water content is less than 0.1%, the temperature is lowered to 105°C and the PO / EO (PO357g, EO2616g) mixture is continuously introduced until the pressure is ≤0.15MPa. After passing through, keep warm and age to negative pressure, cool down and discharge to obtain crude ether, and then press the crude ether with nitrogen to the refining tank for post-treatment. Add 150g of water into the refining kettle, heat up to 80°C and stir for 1 hour, then add 8.64g of phosphoric acid for neutralization and stir for 1 hour, then add 12g of refined preparation and stir for 1 hour, and finally heat up to 120°C and vacuum dehydrate until the water mass fraction is ≤0.08 %, the central control pH is 5.0-7.0, and the refined agent is removed by press...

Embodiment 2

[0029] Add 9.74g of glycerin, 19.26g of sorbitol, and 4.5g of KOH into the polymerization reactor. After nitrogen replacement for 3 times, start vacuuming to -0.98MPa, then raise the temperature to 115°C and start dehydration for 2 hours. When the water content is less than 0.1%, the temperature is lowered to 105°C and the PO / EO (PO59g, EO2912g) mixture is continuously introduced. After passing through, keep warm and age to negative pressure, cool down and discharge to obtain crude ether, and then press the crude ether with nitrogen to the refining tank for post-treatment. Add 150g of water into the refining kettle, heat up to 80°C and stir for 1 hour, then add 8.64g of phosphoric acid for neutralization and stir for 1 hour, then add 12g of refined preparation and stir for 1 hour, and finally heat up to 120°C and vacuum dehydrate until the water mass fraction is ≤0.08 %, the central control pH is 5.0-7.0, and the refined agent is removed by pressure filtration to obtain the fi...

Embodiment 3

[0033] Add 12.5g of glycerin, 15.5g of sucrose, and 9g of KOH into the polymerization reactor. After 3 times of nitrogen replacement, start to pull the vacuum to -0.98MPa, then raise the temperature to 125°C and start dehydration for 2 hours. When the water content is less than 0.1%, the temperature is lowered to 115°C and the PO / EO (PO238g, EO2734g) mixture is continuously introduced. After passing through, keep warm and age to negative pressure, cool down and discharge to obtain crude ether, and then press the crude ether with nitrogen to the refining tank for post-treatment. Add 150g of water into the refining kettle, heat up to 80°C and stir for 1 hour, then add 17.28g of phosphoric acid for neutralization and stir for 1 hour, then add 12g of refined preparation and stir for 1 hour, and finally heat up to 120°C and vacuum dehydrate until the water mass fraction is ≤0.08 %, the central control pH is 5.0-7.0, and the refined agent is removed by pressure filtration to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com