Preparation method for flexible foam polyether polyol for low-density sponge

A polyether polyol and low-density technology is applied in the field of preparation of soft-foam polyether polyol for low-density sponges, which can solve the problems of poor performance, no obvious breakthrough, and inability to realize high molecular weight special polyether polymerization, and achieves Narrow molecular weight distribution, excellent operating latitude, low unsaturation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

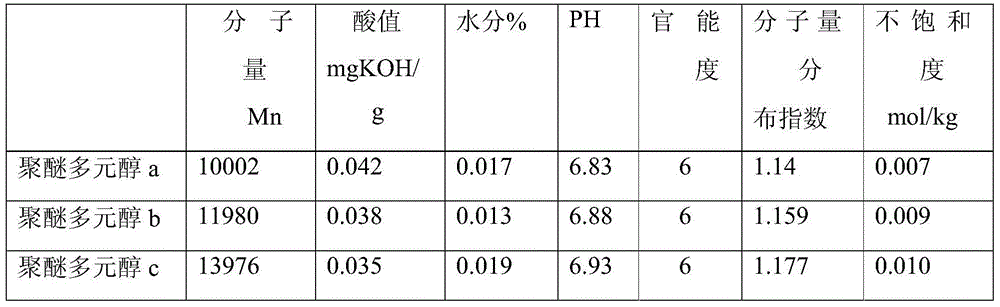

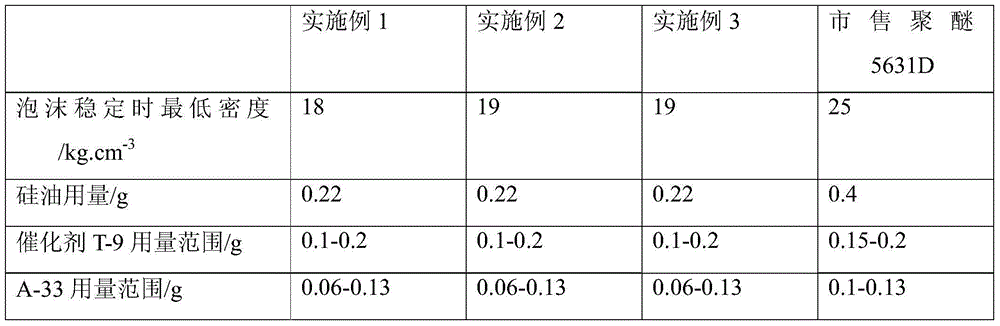

Examples

Embodiment 1

[0024] In a 2L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 182g of solid sorbitol, 48g of 1,3-dimethylimidazoline Ketone, after stirring evenly, add 3.6g KOH, replace nitrogen 5 times, heat up to 70°C, then add 48g propylene oxide to polymerize, stir and react for 1.5h, remove the solvent 1,3-dimethyl in vacuum at -0.10MPa Imidazolinone, then continue to add 970g of propylene oxide in batches, control the reaction temperature at 105°C, and the pressure at 0.16MPa. After the reaction is completed, lower the temperature to 85°C, add 7.02g of phosphoric acid and 36g of distilled water, stir the reaction for 45min, and then add 1.2g Magnesium aluminum silicate, stirred for 30 minutes, dehydrated in vacuum at -0.10MPa for 2 hours, filtered to obtain the intermediate polyether polyol, and set aside.

[0025] Add 240g of intermediate polyether polyol and 0.1...

Embodiment 2

[0027] In a 2L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 182g of solid sorbitol, 40g of 1,3-dimethylimidazoline Ketone, 20g N, N-dimethylformamide, after stirring evenly, add 3gKOH, replace nitrogen 3 times, heat up to 80°C, then add 50g propylene oxide to polymerize, stir and react for 1.5h, then vacuum at -0.10MPa Remove the solvent 1,3-dimethylimidazolinone and N,N-dimethylformamide, then continue to add 768g of propylene oxide in batches, control the reaction temperature at 110°C, and the pressure at 0.18MPa. After the reaction is completed, cool down to 85°C, add 5.85g phosphoric acid and 30g distilled water, stir and react for 45min, then add 1g magnesium silicate and 1.0g aluminum silicate, stir for 30min, vacuum dehydrate at -0.10MPa for 2h, filter to obtain the intermediate polyether polyol, wait use.

[0028] Add 200g of intermediate poly...

Embodiment 3

[0030] In a 2L autoclave equipped with a stirrer, a meter, a heating temperature control device, a cooling device (including an outer jacket and an inner coil) and a pressure sensor, add 182g of solid sorbitol, 40g of 1,3-dimethylimidazoline Ketone, 24g dimethyl sulfoxide, after stirring evenly, add 2.4gKOH, replace with nitrogen 3 times, heat up to 90°C, then add 48g propylene oxide to polymerize, stir for 1.5h, then vacuum remove at -0.10MPa Solvent 1,3-dimethylimidazolinone, N,N-dimethylformamide, and then continue to add 570g of propylene oxide in batches, control the reaction temperature to 120°C, and the pressure to 0.20MPa. After the reaction is completed, cool down to 85°C , add 4.68g of phosphoric acid and 24g of distilled water, stir for 45min, then add 2.4g of aluminum magnesium silicate, stir for 30min, vacuum dehydrate at -0.10MPa for 2h, filter to obtain the intermediate polyether polyol, and set aside.

[0031] Add 160g of intermediate polyether polyol and 0.07g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com