Blast furnace gravity ash-based SCR denitration catalyst as well as preparation method and application thereof

A technology of denitrification catalyst and gravity ash, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. It can solve the problems of polluting soil and water sources, wasting land resources, ecological impact, etc., and achieve high NOx conversion High efficiency, simple production and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

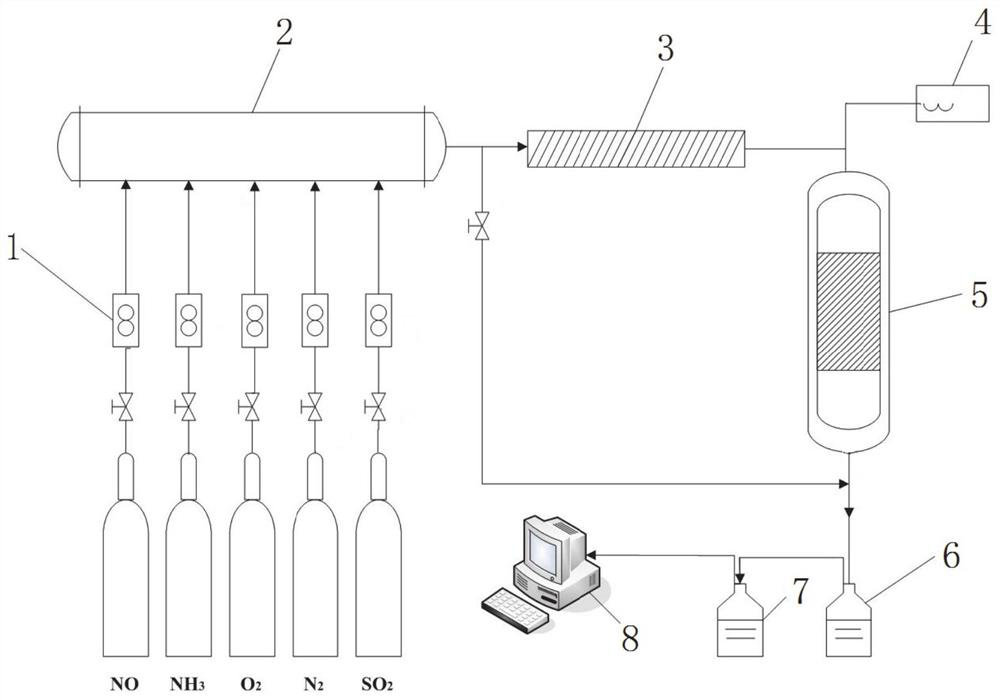

Method used

Image

Examples

Embodiment 1

[0038] (1) Precursor preparation

[0039] Take a certain amount of blast furnace gravity ash, dry it in a blast oven at 105°C for 24 hours, use a coal mill to crush it into small particles, and use a standard inspection sieve to sieve the particles below 100 mesh for use. Take a certain amount of 100-mesh blast furnace gravity ash and mix with 4.5mol / L nitric acid solution, the liquid-solid ratio is 6:1, then stir in a 90°C water bath, and then perform solid-liquid separation to obtain a solution. The composition of gravity ash is shown in Table 1.

[0040] Table 1 Gravity Ash Composition

[0041]

[0042] The leaching solution was detected by an inductively coupled plasma optical emission spectrometer (ICP-OES, PerkinElmer Optima7000DV), and Table 2 was obtained. It was found that the solution mainly contained Fe 3+ 、Al 3+ , Ca 2+ , Mg 2+ , Zn 2+ Wait.

[0043] Table 2 Extract composition

[0044]

[0045](2) pH adjustment

[0046] Ammonia water was added drop...

Embodiment 2

[0050] (1) Precursor preparation

[0051] Take a certain amount of blast furnace gravity ash, dry it in a blast oven at 105°C for 24 hours, use a coal mill to crush it into small particles, and use a standard inspection sieve to sieve the particles below 100 mesh for use. Take a certain amount of 100-mesh blast furnace gravity ash and mix with 4.5mol / L nitric acid solution, the liquid-solid ratio is 6:1, then stir in a 90°C water bath, and then perform solid-liquid separation to obtain a solution.

[0052] (2) pH adjustment

[0053] Ammonia water was added dropwise to the obtained solution to adjust the pH value to 4.5-5.5 to obtain solid phase precipitation, and then washed several times with deionized water until neutral.

[0054] (3) Drying and calcining.

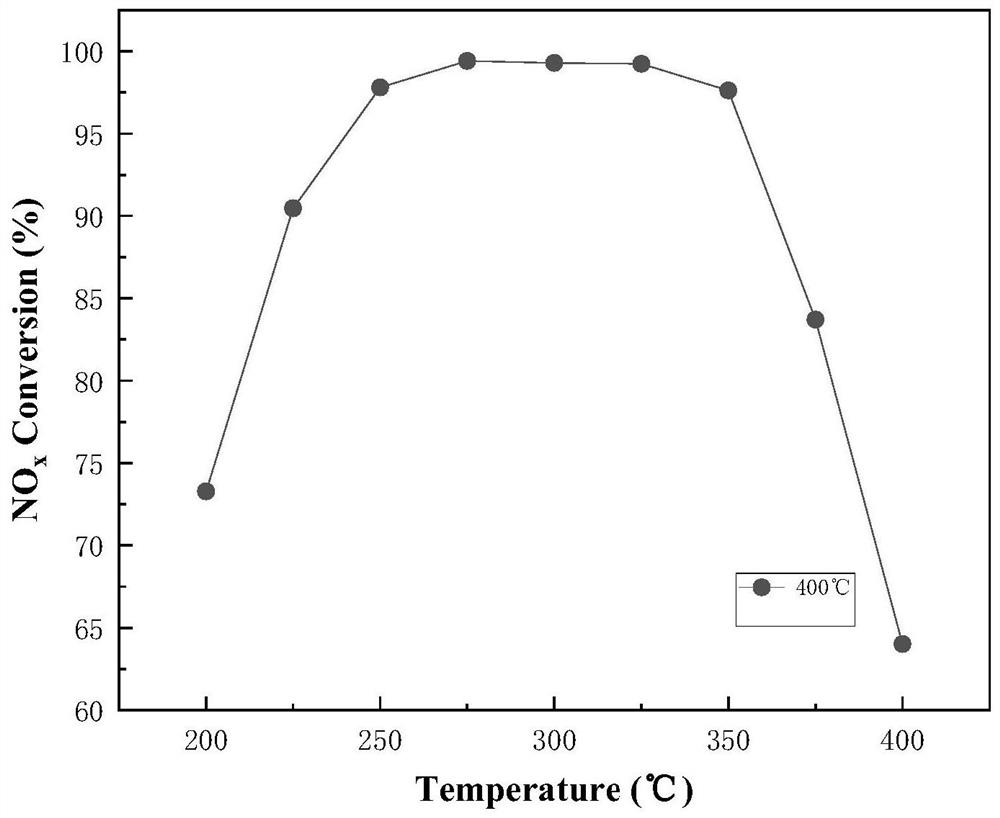

[0055] The neutral precipitate was dried at 105° C. for 12 h in a blast drying oven to constant weight. Finally, the temperature was raised from room temperature to 450°C at a rate of 5°C / min in a muffle furnace, and ...

Embodiment 3

[0057] (1) Precursor preparation

[0058] Take a certain amount of blast furnace gravity ash, dry it in a blast oven at 105°C for 24 hours, use a coal mill to crush it into small particles, and use a standard inspection sieve to sieve the particles below 100 mesh for use. Take a certain amount of 100-mesh blast furnace gravity ash and mix with 4.5mol / L nitric acid solution, the liquid-solid ratio is 6:1, then stir in a 90°C water bath, and then perform solid-liquid separation to obtain a solution.

[0059] (2) pH adjustment

[0060] Ammonia water was added dropwise to the obtained solution to adjust the pH value to 4.5-5.5 to obtain solid phase precipitation, and then washed several times with deionized water until neutral.

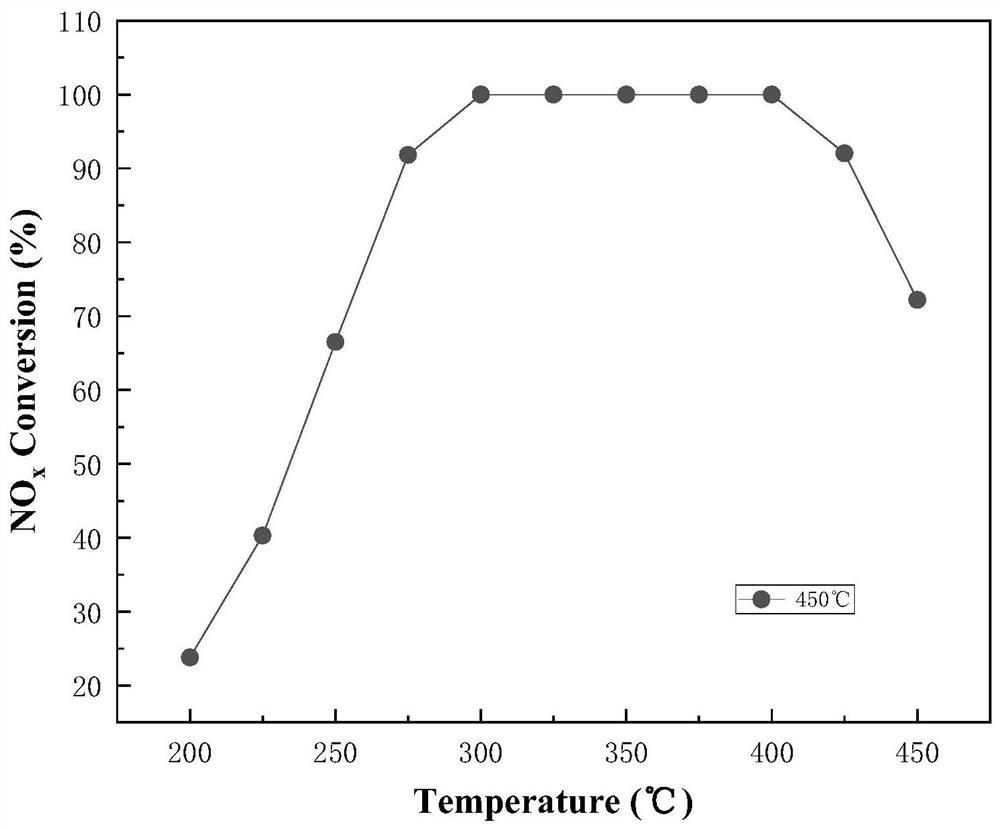

[0061] (3) Drying and calcining.

[0062] The neutral precipitate was dried at 105° C. for 12 h in a blast drying oven to constant weight. Finally, the temperature was raised from room temperature to 500°C at a rate of 5°C / min in a muffle furnace, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com