Cu-SAPO-34 molecular sieve, preparation method thereof and application of Cu-SAPO-34 molecular sieve in selective catalytic reduction denitration

A technology of cu-sapo-34 and molecular sieve, which is applied in the direction of molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of narrow activity temperature window, high preparation cost, and poor activity at low temperature, and achieve a wide activity temperature window, Low cost, enhanced low temperature activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment discloses a Cu-SAPO-34 molecular sieve catalyst. The preparation method of the Cu-SAPO-34 molecular sieve catalyst comprises the following steps: mixing 8.8g of orthophosphoric acid with 30g of deionized water, and then mixing 5.1g of Add pseudo-boehmite slowly and stir until completely dissolved; add 4g of silica sol and stir for 2h, add 8g of morpholine, and then add 0.75g of cuproammonia complex dropwise; after stirring evenly, add ammonia dropwise to adjust the pH From 7 to 8, stir vigorously for 12 hours. The Cu-SAPO-34 molecular sieve initial gel was obtained. The mixture was transferred to a hydrothermal crystallization kettle, crystallized at 180° C. for 48 hours, and cooled to room temperature; after treatment, it was pressed into tablets to obtain a Cu-SAPO-34 molecular sieve catalyst.

[0034] On the fixed bed device, the Cu-SAPO-34 molecular sieve catalyst of this embodiment was used to carry out the simulation test of removing NOx from moto...

Embodiment 2~3

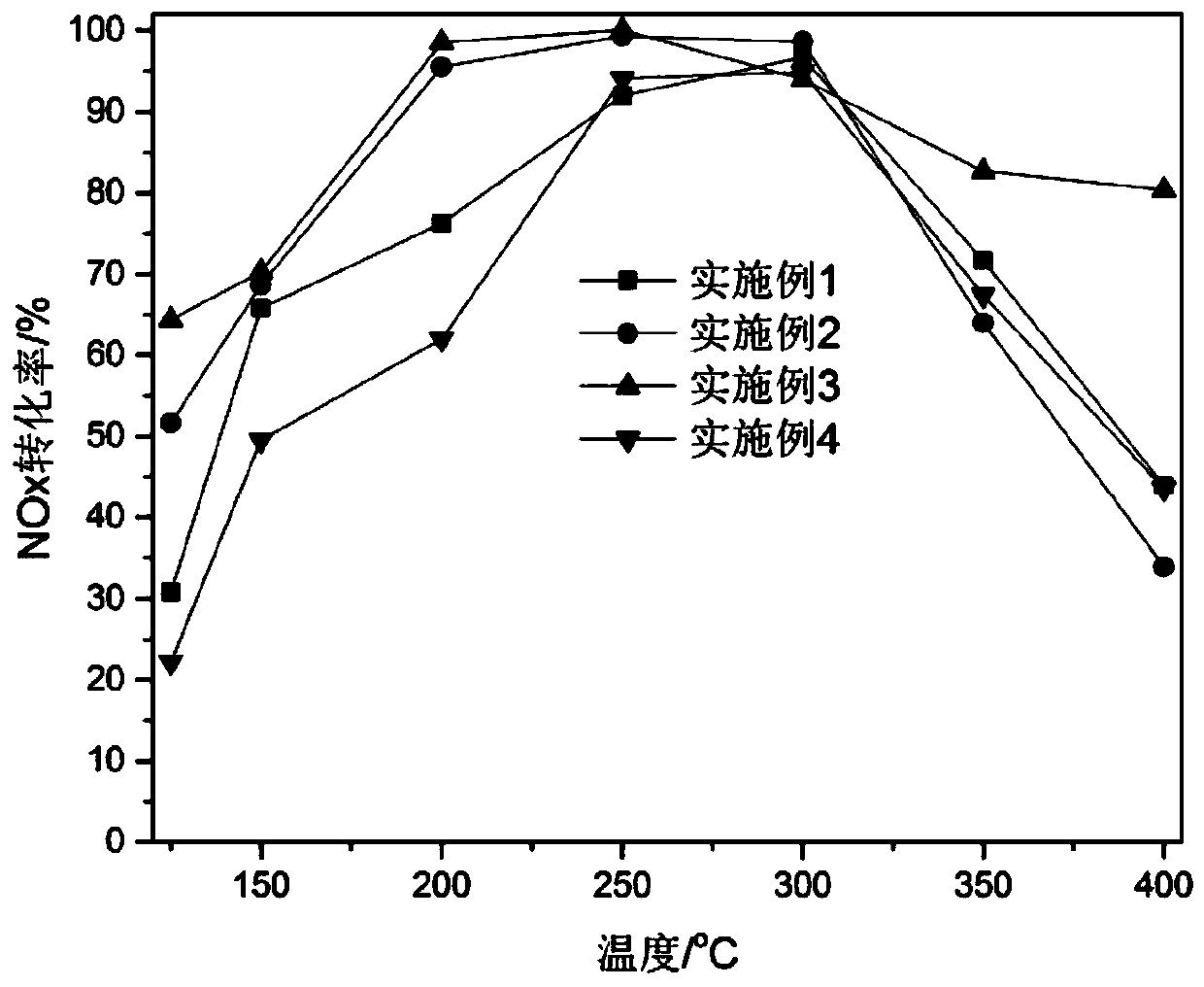

[0036] The Cu-SAPO-34 molecular sieve catalyst was prepared according to the steps and conditions of Example 1 and the activity test was carried out. To change the addition amount of silica sol, the changed conditions are listed in Table 1 and Table 2. The SCR activity test result of the Cu-SAPO-34 molecular sieve catalyst prepared by implementation cases 2-3 after calcination is in figure 1 given in.

Embodiment 4

[0038] This embodiment discloses a Cu-SAPO-34 molecular sieve catalyst. The preparation method of the Cu-SAPO-34 molecular sieve catalyst comprises the following steps: mixing 8.8g of orthophosphoric acid with 30g of deionized water, and then mixing 5.1g of Slowly add pseudo-boehmite and stir until completely dissolved; add 8g of silica sol and stir for 2h, add 8g of morpholine, and then add 0.75g of cuproammonia complex dropwise; after stirring evenly, add ammonia dropwise to adjust the pH From 7 to 8, stir vigorously for 12 hours. The Cu-SAPO-34 molecular sieve initial gel was obtained. The mixture was transferred to a hydrothermal crystallization kettle, crystallized at 180° C. for 48 hours, and cooled to room temperature; after treatment, it was pressed into tablets to obtain a Cu-SAPO-34 molecular sieve catalyst.

[0039] On the fixed bed device, the Cu-SAPO-34 molecular sieve catalyst of this embodiment was used to carry out the simulation test of removing NOx from moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com