Cold forging gear steel and preparation method thereof

A gear steel and cold forging technology, applied in the field of steel, can solve problems such as low hardness cold plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A preparation method of cold forged gear steel, the method comprising:

[0046] The smelted molten steel is sequentially poured and continuously cast to obtain a slab;

[0047] Heating the cast slab, and finally descaling to obtain the cast slab after descaling;

[0048] Rolling and cooling the cast slab after descaling in sequence to obtain the gear steel;

[0049] The rolling includes rough rolling and finishing rolling, the starting temperature of the rough rolling is 1050-1100°C, the temperature of the finishing rolling is 850-950°C, and the total deformation of the finishing rolling unit is 40% ~60%.

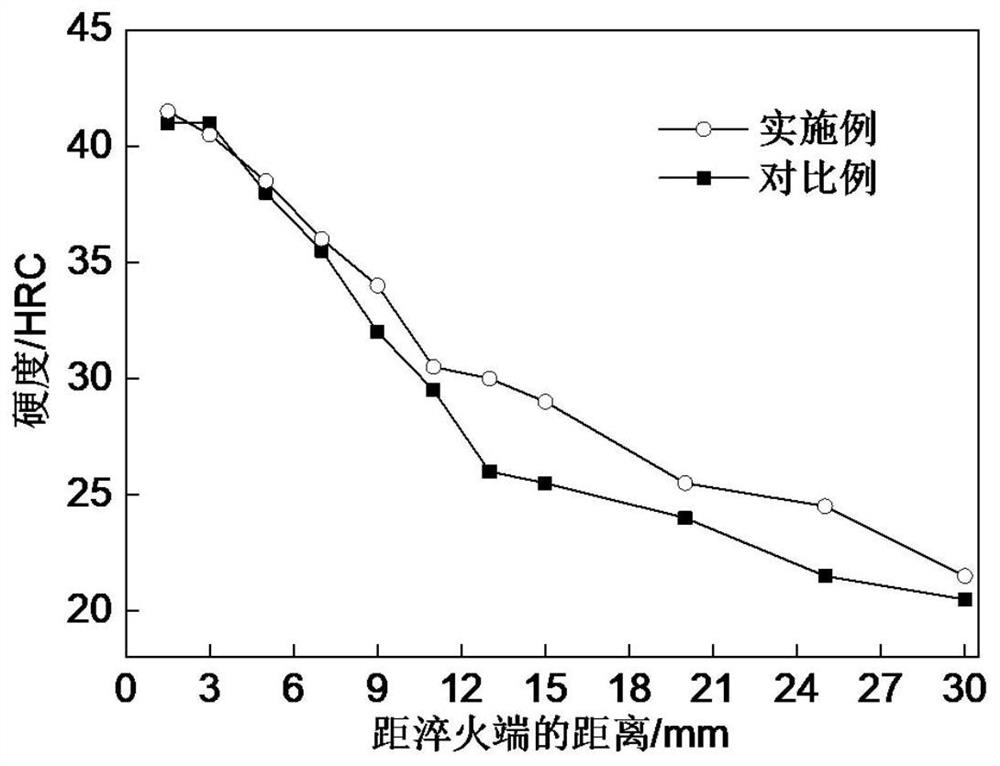

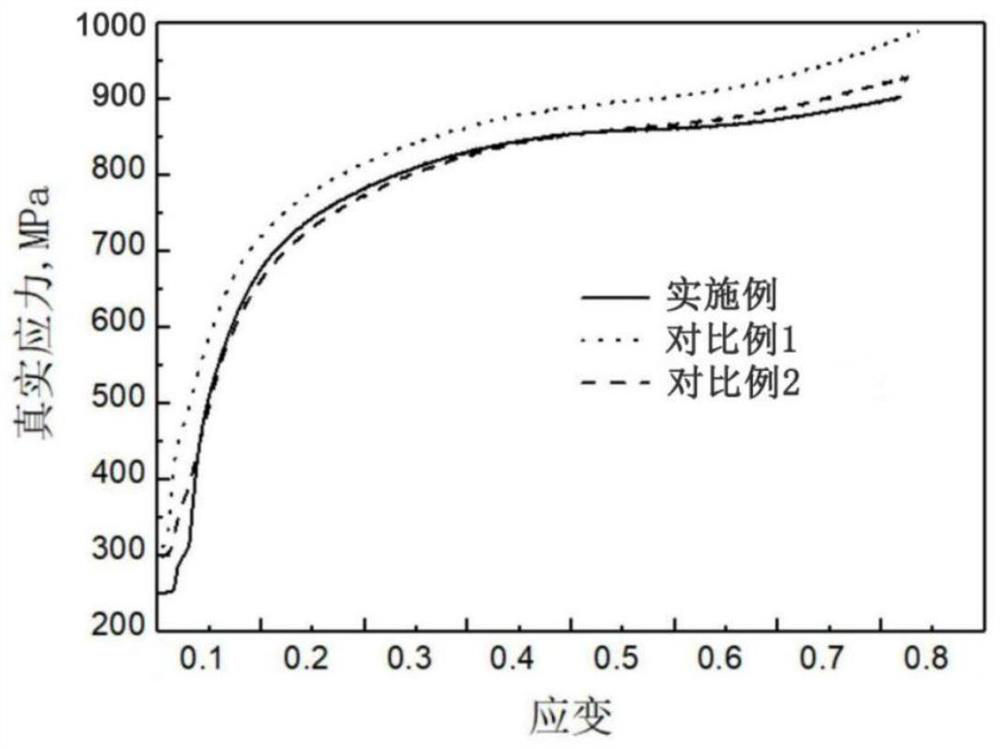

[0050] Through the method of low-temperature and large-deformation finish rolling, the number of deformation bands inside the austenite grains is greatly increased, and a large number of nucleation sites are provided for the ferrite transformation to promote the ferrite transformation. The method of slow cooling after rolling is adopted. , increasing the residence...

Embodiment 1

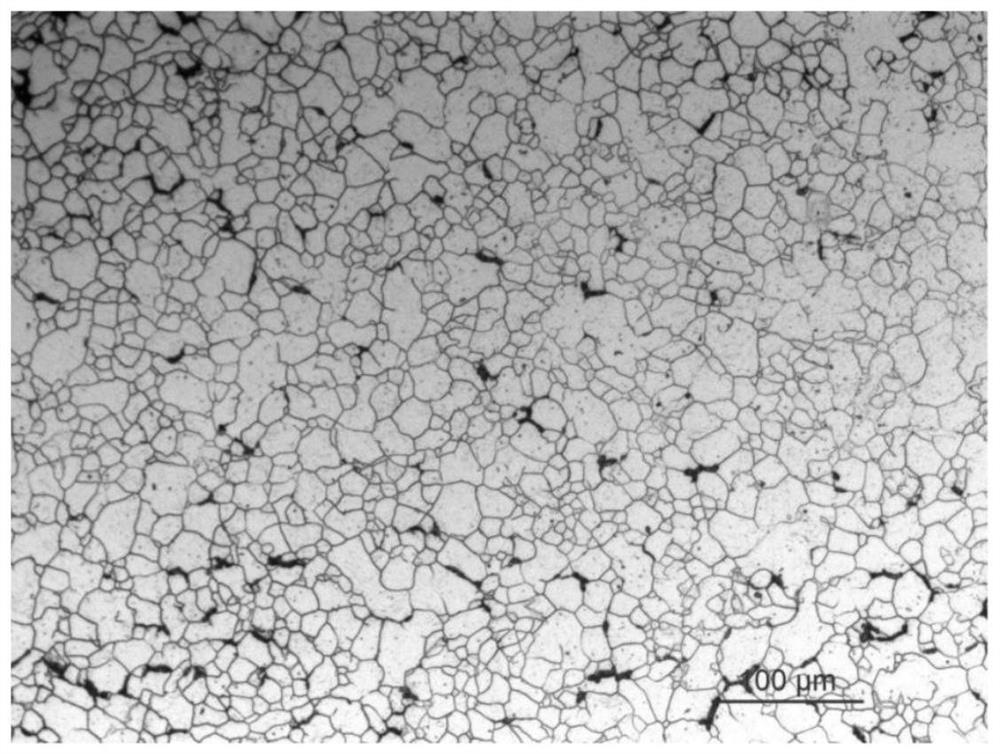

[0068] In this example, the constituent elements and mass percentages used in the gear steel are: C 0.17%, Si 0.08%, Mn 0.60%, P 0.010%, S 0.025%, Cr 1.30%, Ti 0.04%, Al 0.033%, Cu 0.13%, N0.0065%, the balance is Fe and unavoidable impurities. The metallographic structure of the gear steel includes austenite, and the grain size of the austenite is grade 6-7.

[0069] The production specification is Φ80mm new cold forged gear steel. The specific control parameters are:

[0070] (1) Electric furnace is used for smelting, and the carbon content (mass fraction) at the end of tapping is controlled at 0.10%; then it enters the LF furnace for out-of-furnace refining, and feeds aluminum wire 4.5m / t after the seat cladding, and controls the target aluminum content of J1 to reach 0.060%, Add lime and fluorite according to slag condition and sulfur content during tapping to ensure good slag fluidity; then carry out VD vacuum degassing on the molten steel, the pumping time is 5 minutes, ...

Embodiment 2

[0074] In this embodiment, the constituent elements and mass percentages of the gear steel are: C: 0.15%, Si: 0.05%, Mn: 0.30%, Cr: 0.80%, Ti: 0-0.05%, and the balance is Fe and not Avoid impurities. The metallographic structure of the gear steel includes austenite, and the grain size of the austenite is grade 6-7.

[0075] A kind of cold forging gear steel and preparation method thereof, described method comprises continuous casting, rolling successively, and specific process parameter is as follows:

[0076] pouring the molten steel at a temperature of 1500°C to obtain a slab;

[0077] Heating the billet at a temperature of 1150°C for 2.5 hours, and then descaling;

[0078] The rolling start temperature in the rolling is 1050°C, and the finish rolling temperature in the rolling is 850°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com