Cold forging gear steel containing Nb and B and preparation method thereof

A gear steel, cold forging technology, applied in the field of gear steel, can solve the problems of coarse grain and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] A kind of preparation method that contains Nb, B cold forging gear steel, described method comprises:

[0049] The smelted molten steel is sequentially poured and continuously cast to obtain a slab;

[0050] Heating the cast slab, and finally descaling to obtain the cast slab after descaling;

[0051] Rolling and cooling the cast slab after descaling in sequence to obtain the gear steel;

[0052] The rolling includes rough rolling and finish rolling, the starting temperature of the rough rolling is 1050-1100°C, the temperature of the finish rolling is 850-950°C, and the total deformation of the finish rolling unit is 40%- 60%.

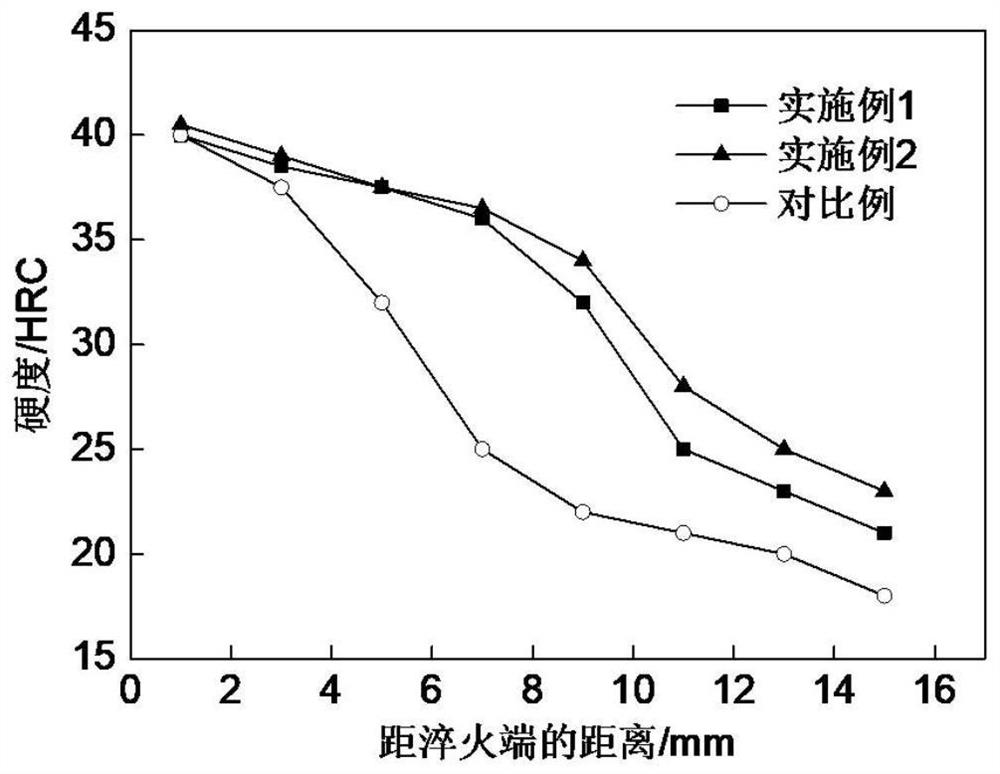

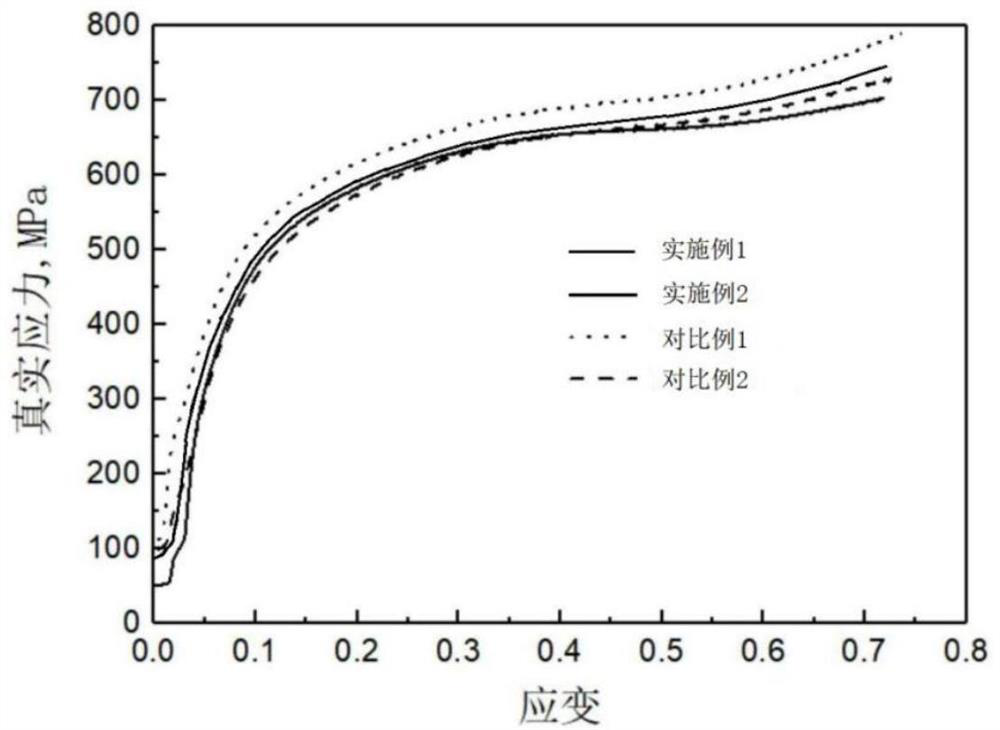

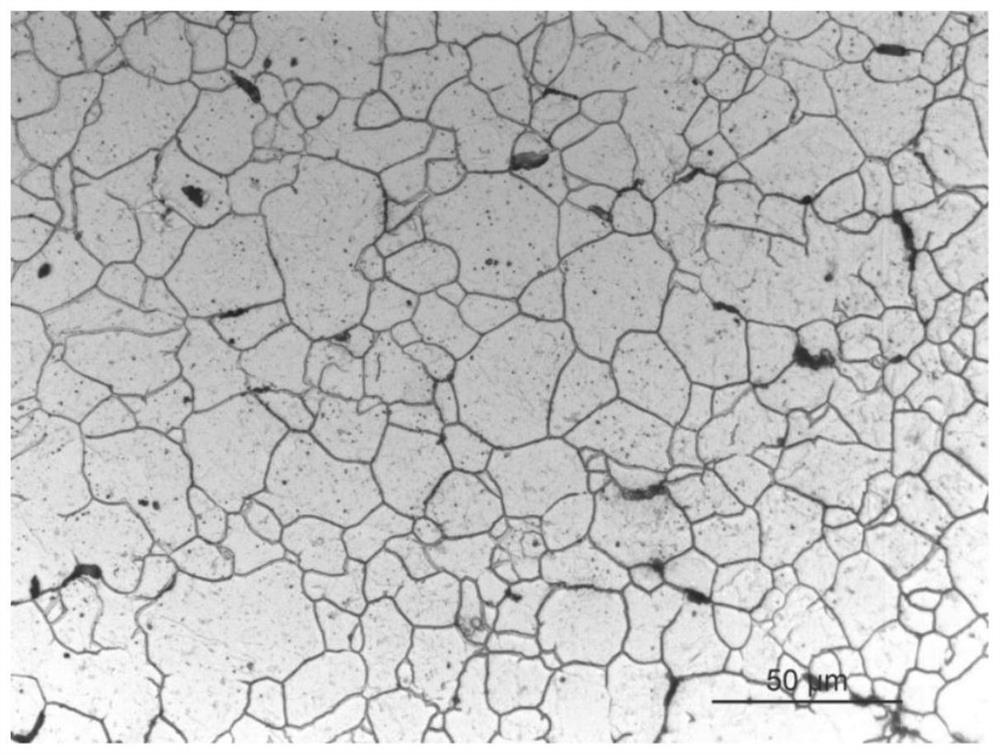

[0053] Utilize the pinning effect of precipitates formed after cold forging and carburizing to prevent the growth of austenite grains, thereby avoiding the local coarse grain phenomenon, and at the same time, it can compensate for the decrease in hardenability after reducing the content of Si and Mn to meet the requirements of gears. Hardenab...

Embodiment 1

[0069] In this embodiment, the constituent elements and mass percentages used in the gear steel are: C 0.18%, Si 0.07%, Mn 0.50%, P 0.011%, S 0.005%, Cr 1.15%, Nb 0.02%, B 0.0015%, Cu 0.11%, N0.0040%, the balance is Fe and unavoidable impurities.

[0070] The production specification is Φ60mm new cold forged gear steel. The specific control parameters are:

[0071] (1) Electric furnace is used for smelting, and the carbon content (mass fraction) at the end of tapping is controlled at 0.12%; then it enters the LF furnace for out-of-furnace refining, and feeds aluminum wire 5m / t after the seat ladle, and controls the target aluminum content of the primary composition J1 of refining to the station When reaching 0.060%, add lime and fluorite according to the slag condition and the sulfur content during tapping to ensure good fluidity of the slag; then carry out VD vacuum degassing on the molten steel, the pumping time is 4min, and the vacuum holding time is less than 67Pa Up to 1...

Embodiment 2

[0075] In this embodiment, the constituent elements and mass percentages used in the gear steel are: C 0.18%, Si 0.07%, Mn 0.50%, P 0.011%, S 0.005%, Cr 1.15%, Nb 0.02%, B 0.0015%, Ti 0.05%, Al0.025%, Cu 0.11%, N 0.0045%, the balance is Fe and unavoidable impurities.

[0076] The production specification is Φ120mm new type cold forged gear steel. The specific control parameters are:

[0077] (1) Converter smelting is adopted, and the carbon content (mass fraction) at the end of tapping is controlled at 0.08%; then it enters the LF furnace for out-of-furnace refining, and feeds aluminum wire 4m / t after the seat ladle, and controls the target aluminum content of the primary composition J1 of the refining station Reach 0.045%, add lime and fluorite according to slag condition and sulfur content during tapping to ensure good slag fluidity; then carry out VOD vacuum degassing on molten steel, pumping time is 7min, less than 67Pa vacuum holding time up to 10min.

[0078] (2) Prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com