Phase transformation memory storing unit and producing method thereof

A technology of phase-change memory and storage unit, applied in the field of microelectronics, which can solve the problems of reducing operating current, large device operating current, and high power consumption, and achieve the effect of reducing contact area, small contact area, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A specific preparation process of a phase change memory storage unit is as follows:

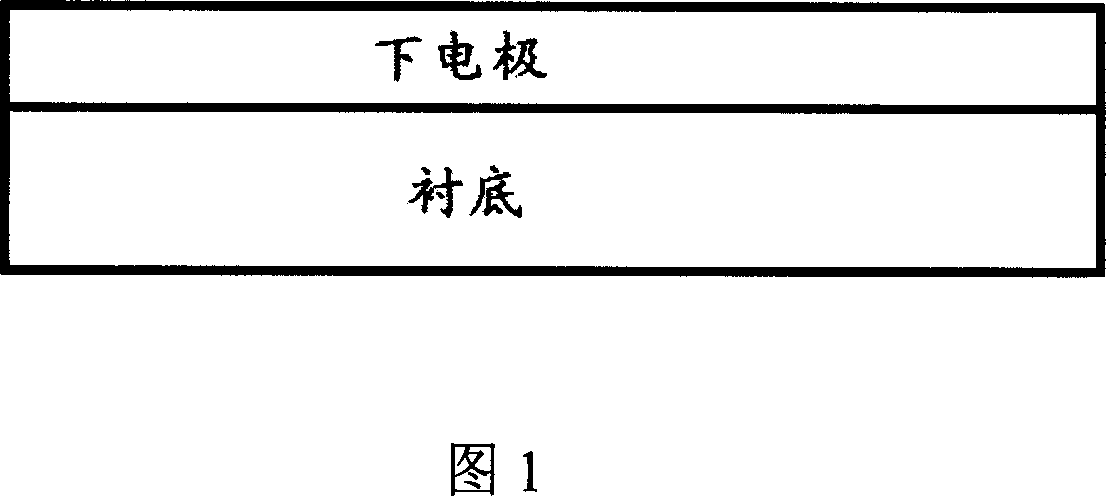

[0035] 1) covered with SiO 2 A layer of Al lower electrode layer was prepared by DC magnetron sputtering on the silicon substrate, and the SiO on the silicon substrate 2 Prepared by thermal oxidation method, SiO 2 The thickness of the material is 1000 nm. The process parameters for preparing Al electrodes are: the background pressure is 2×10 -4 Pa, the Ar gas pressure during sputtering is 0.2Pa, the sputtering power is 200W, the substrate temperature is 25°C, and the film thickness is 400nm. (figure 1)

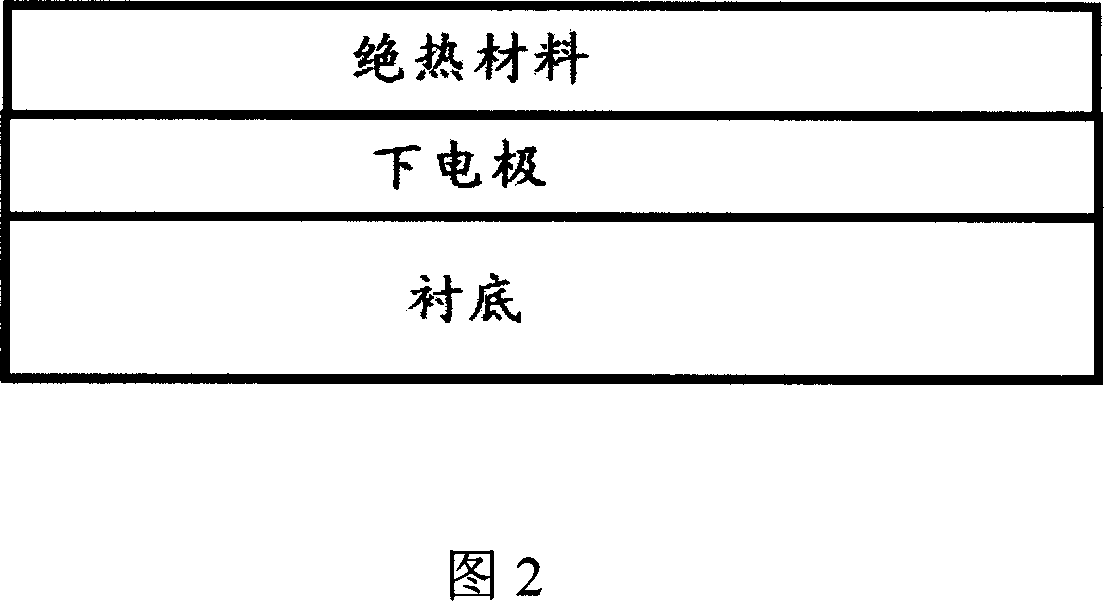

[0036] 2) Preparation of SiO on Al electrode 2 The thermal insulation material layer is a chemical vapor deposition method, and the thickness of the film is 500nm. (figure 2)

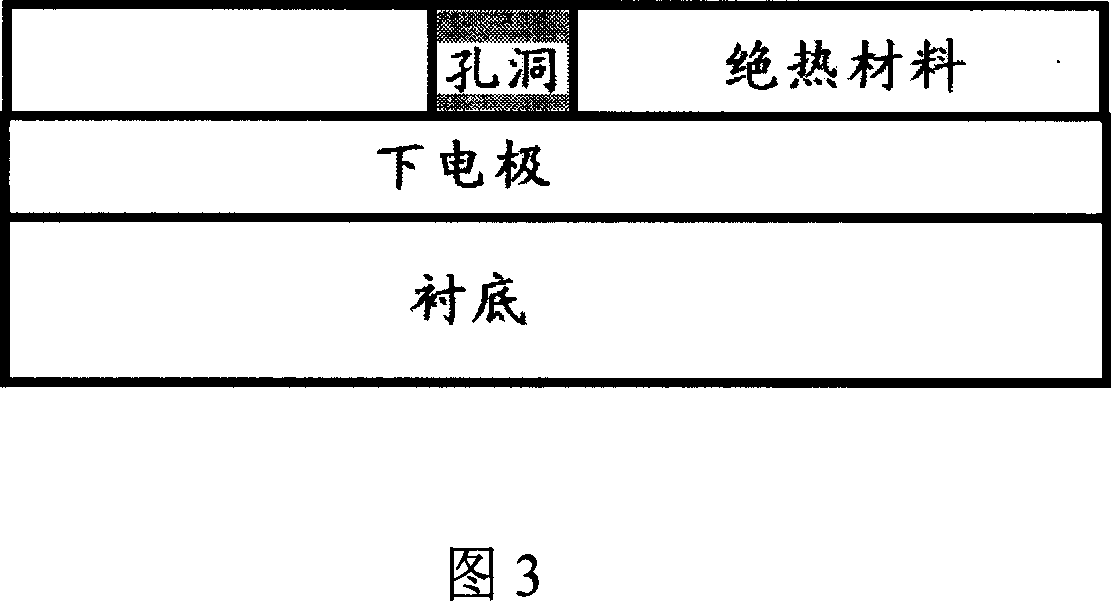

[0037] 3) Using 0.18μm standard process on SiO 2 Holes are prepared in the heat insulating material layer, and the diameter of the holes is 260 nm. (image 3)

[0038] 4) Use chemical vapor deposition t...

Embodiment 2

[0051] The W columnar electrode in Embodiment 1 is changed to TiN, and the rest is similar to Embodiment 1.

Embodiment 3

[0053] The Ge of embodiment 1 and embodiment 2 2 Sb 2 Te 5 Phase change film changed to Si 2 Sb 2 Te 5 Phase change thin film, all the other are similar to embodiment 1 and embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com