High strength thermoplastic polyurethane solid-solid phase change energy storage material and preparation method thereof

A phase-change energy storage material, thermoplastic polyurethane technology, applied in the field of thermoplastic polyurethane elastomers, can solve the problems of low elongation at break, poor mechanical properties, and limited applications, and achieve excellent mechanical properties, easy operation, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

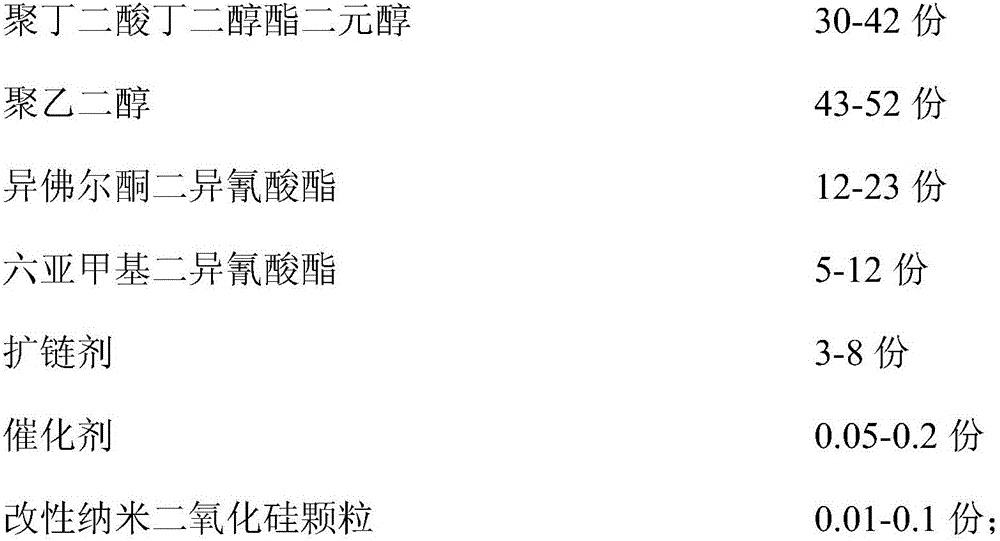

[0047] A thermoplastic polyurethane solid-solid phase change energy storage material, the thermoplastic polyurethane solid-solid phase change energy storage material is prepared from the following raw materials in parts by weight:

[0048]

[0049] Wherein, the number average molecular weight of the polybutylene succinate diol is 8000-8500, and the number average molecular weight of the polyethylene glycol is 7500-8000.

[0050] The modified nano silicon dioxide particles are silicon dioxide nanoparticles modified by γ-glycidyl ether propyl trimethoxysilane; the particle size of the modified nano silicon dioxide particles is 15-50nm.

[0051] The chain extender is ethylene glycol.

[0052] The catalyst is dibutyltin dilaurate.

[0053] The preparation method of the thermoplastic polyurethane solid-solid phase change energy storage material comprises the following steps:

[0054] (1) dehydrating the polybutylene succinate diol and polyethylene glycol in the formula amount ...

Embodiment 2

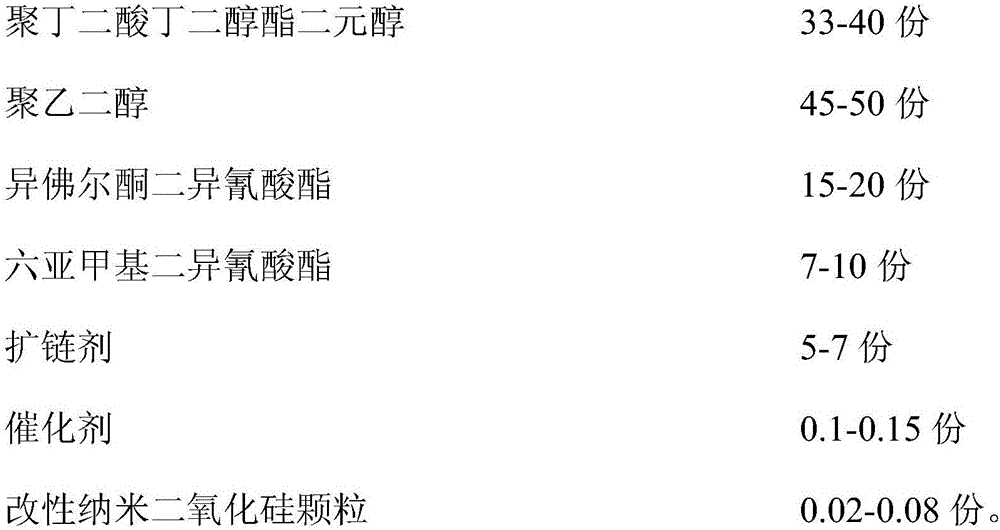

[0059] A thermoplastic polyurethane solid-solid phase change energy storage material, the thermoplastic polyurethane solid-solid phase change energy storage material is prepared from the following raw materials in parts by weight:

[0060]

[0061] Wherein, the number average molecular weight of the polybutylene succinate diol is 7000-7500, and the number average molecular weight of the polyethylene glycol is 6000-6500.

[0062] The modified nano silicon dioxide particles are silicon dioxide nanoparticles modified by γ-glycidyl ether propyl trimethoxysilane; the particle size of the modified nano silicon dioxide particles is 50-150nm.

[0063] The chain extender is 1,4-butanediol and 1,6-hexanediol.

[0064] The catalyst is stannous octoate.

[0065] The preparation method of the thermoplastic polyurethane solid-solid phase change energy storage material comprises the following steps:

[0066] (1) dehydrating the polybutylene succinate diol and polyethylene glycol of the ...

Embodiment 3

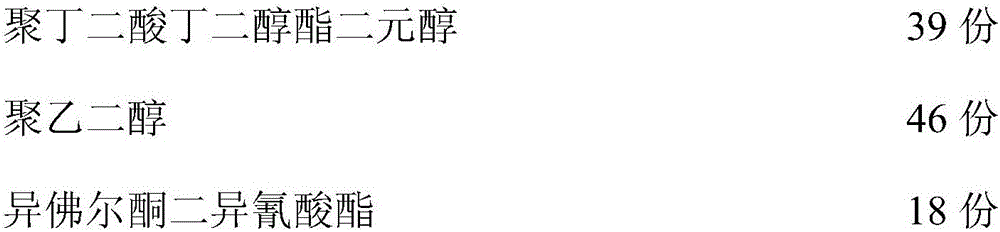

[0071] A thermoplastic polyurethane solid-solid phase change energy storage material, the thermoplastic polyurethane solid-solid phase change energy storage material is prepared from the following raw materials in parts by weight:

[0072]

[0073] Wherein, the number average molecular weight of the polybutylene succinate diol is 7600-8000; the number average molecular weight of the polyethylene glycol is 6700-7200.

[0074] The modified nano silicon dioxide particles are silicon dioxide nanoparticles modified by γ-glycidyl ether propyl trimethoxysilane; the particle diameter of the modified nano silicon dioxide particles is 200-300nm.

[0075] The chain extender is ethylene glycol and 1,4-butanediol with a mass ratio of 1:1.

[0076] The catalyst is stannous octoate and zinc octoate.

[0077] The preparation method of the thermoplastic polyurethane solid-solid phase change energy storage material comprises the following steps:

[0078] (1) Dehydrating the polybutylene su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com