5182-0 aluminum alloy sheet preparation method for automobiles

An aluminum alloy plate and aluminum alloy technology, applied in the field of aluminum alloy manufacturing, can solve problems such as cracking, uneven grain structure, large deformation of aluminum alloy plate, etc., to increase annealing temperature, improve grain structure, and improve performance stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

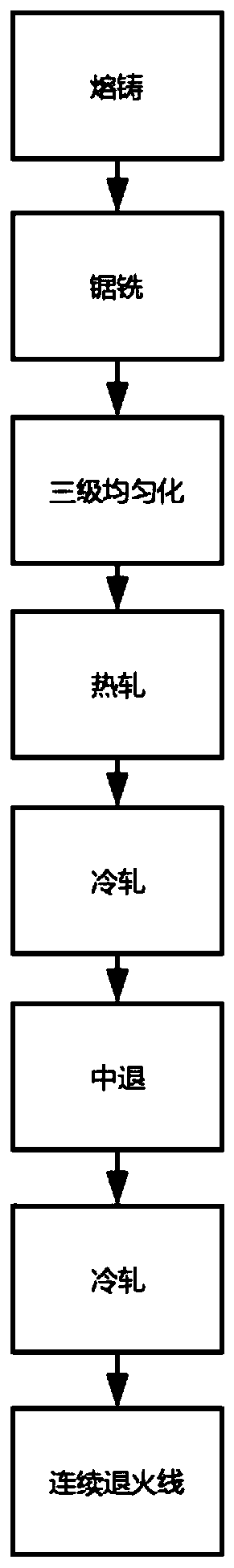

[0033] Such as figure 1 Shown is a method for preparing a 5182-O state aluminum alloy plate for automobiles, comprising the following steps:

[0034] A. Ingredients: The 5182 aluminum alloy raw materials are batched according to the weight percentage, and the mass percentage ratio of each element of the aluminum alloy raw materials is as follows:

[0035] element Si Fe Cu mn Mg Cr Zn Ti Ni Impurities Al content 0.06 0.179 0.05 0.20 4.8 0.1 0.05 0.1 0.1 0.03 margin

[0036]B. Melting and casting: Add the prepared aluminum alloy raw materials into the smelting furnace and mix them evenly to melt them into liquid aluminum alloys. After standing still, refining, slag removal, online degassing, and filtering processes, the liquid aluminum alloys are melted and cast into aluminum alloys. Ingot casting, adding Al-5Ti-B wire refining agent during the refining process of molten aluminum, using double rotors for online degassing, and t...

Embodiment 2

[0043] The difference between embodiment 2 and embodiment 1 is that the thickness of the aluminum alloy coil after hot rolling in step E is 4.0 mm.

Embodiment 3

[0045] The difference between embodiment 3 and embodiment 1 is that the thickness of the aluminum alloy coil after hot rolling in step E is 3.0 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com