Lithium-sulfur battery conductive agent based on nano transition metal phosphide/carbon composite material as well as preparation method and application of lithium-sulfur battery conductive agent

A carbon composite material, transition metal technology, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as single function and pure electrical conductivity, and achieve overall stability and improve electrical conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

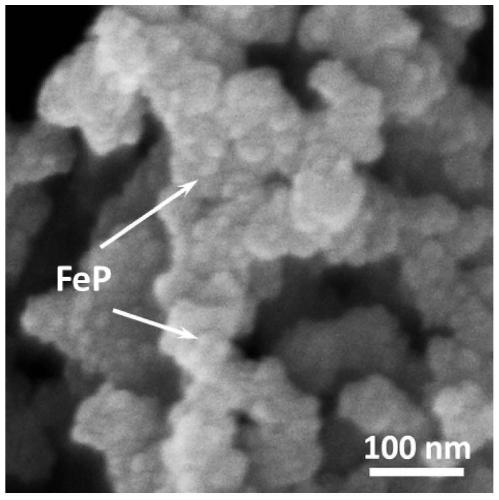

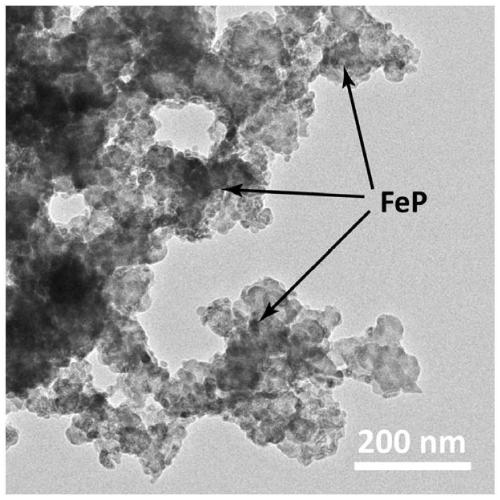

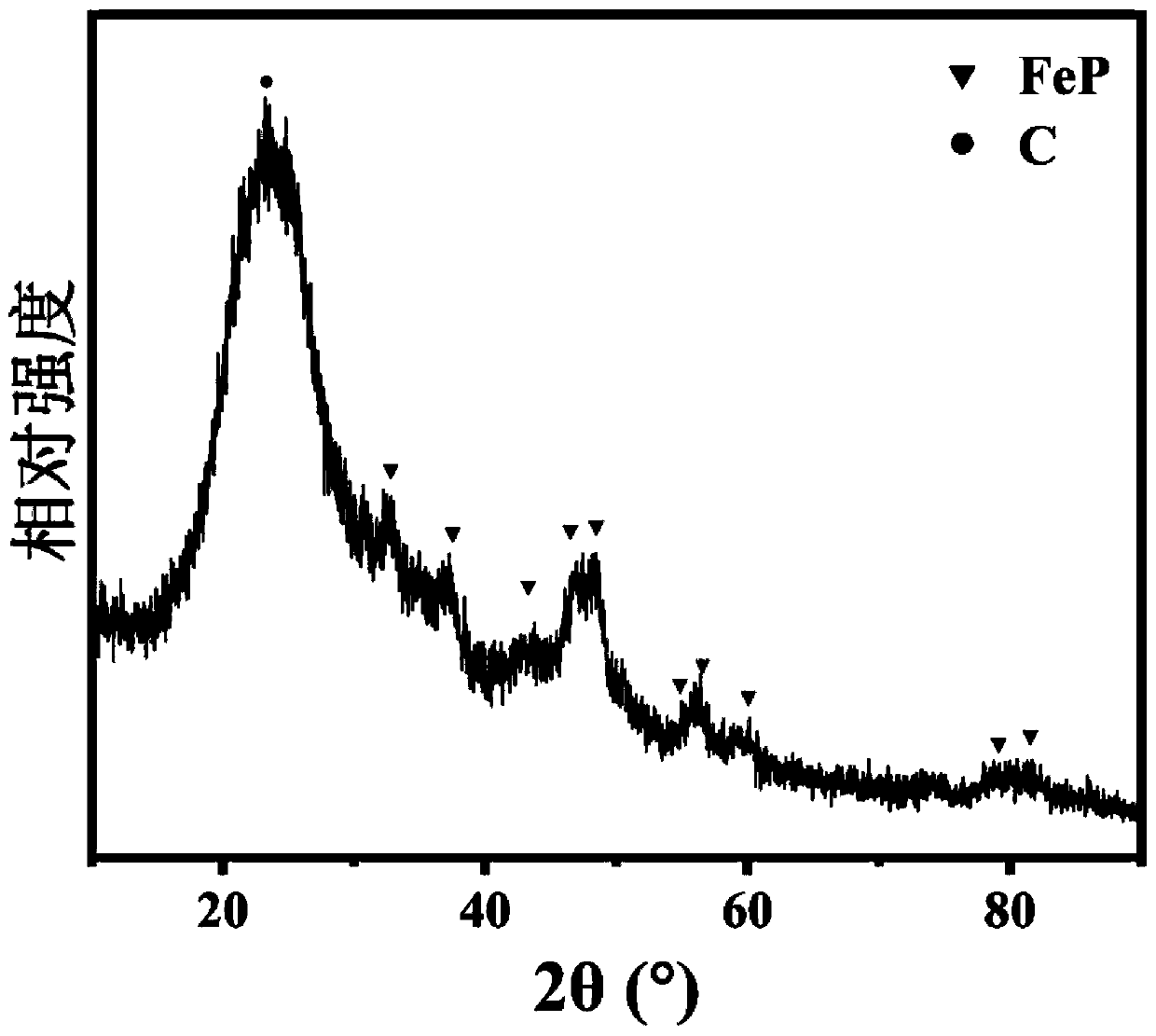

[0068] 1. A preparation of a nano-transition metal phosphide / carbon composite material, comprising the steps of:

[0069] (1) Weigh 1g Super P (conductive carbon black), measure 10mL 30wt.% hydrogen peroxide, put the two into a stainless steel reactor with a capacity of 100mL lined with Teflon, and react hydrothermally at 150°C for 4h, The black powder obtained after the reaction was centrifuged and washed with deionized water for 3 times, and then air-dried at 120°C for 3 hours to obtain Super P with oxygen-containing groups.

[0070] (2) Add 80 mg of the Super P with oxygen-containing groups and 3.2 mmol of ferric nitrate to 160 mL of N,N-dimethylformamide and place them in a sealed glass bottle for ultrasonic dispersion for 1 hour to form 0.2 mol / L Fe 3+ Suspension. The mixed solution was transferred to an oil bath environment at 60° C., and stirred for 14 h. The reacted mixed solution is centrifugally washed and separated, and then freeze-dried to obtain an iron oxide / Su...

no. 2 example

[0082] 1. A preparation of a nano-transition metal phosphide / carbon composite material, comprising the steps of:

[0083] (1) Weigh 1g Super P (conductive carbon black), measure 10mL 30wt.% hydrogen peroxide, put the two into a stainless steel reactor with a capacity of 100mL lined with Teflon, and react hydrothermally at 150°C for 4h, The black powder obtained after the reaction was centrifuged and washed with deionized water for 3 times, and then air-dried at 120°C for 3 hours to obtain Super P with oxygen-containing groups.

[0084] (2) 80 mg of the Super P with oxygen-containing groups and 0.16 mol of ferric nitrate are added to 80 mL of deionized water and placed in a sealed glass bottle for ultrasonic dispersion for 1 h to form 2 mol / L Fe 3+ Suspension. The reaction was stirred at 20°C for 8h. After the reacted mixed solution was centrifugally cleaned and separated, and then air-dried at 60° C., the iron oxide / Super P composite material was obtained.

[0085] (3) The ...

no. 3 example

[0093] 1. A preparation of a nano-transition metal phosphide / carbon composite material, comprising the steps of:

[0094] (1) Weigh 1g Super P (conductive carbon black), measure 10mL 30wt.% hydrogen peroxide, put the two into a stainless steel reactor with a capacity of 100mL lined with Teflon, react at 150°C for 4h, and react The obtained black powder was centrifuged three times with deionized water and then air-dried at 120°C for 3 hours to obtain Super P with oxygen-containing groups.

[0095] (2) Add 60 mg of the Super P with oxygen-containing groups, 2.8 mol of cobalt acetate and 10.8 mL of 25 wt.% ammonia water into 140 mL of absolute ethanol, and then place it in a stoppered flask for ultrasonic dispersion for 15 minutes to form a 0.2 mol / Co of L 2+ Suspension. And the mixed solution was transferred to an 80°C oil bath environment, and stirred for 12 hours. After the reaction, the mixed solution was centrifugally cleaned and separated, and then freeze-dried to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com