Rolling process of improving 38CrMoAl steel rolling state structure

A technology of microstructure and steel rolling, applied in the field of rolling process for improving the as-rolled microstructure of 38CrMoAl steel, can solve the problems of cumbersome steps, high hardness, poor effect, etc., to reduce material loss, production efficiency, hardness and mechanical properties The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

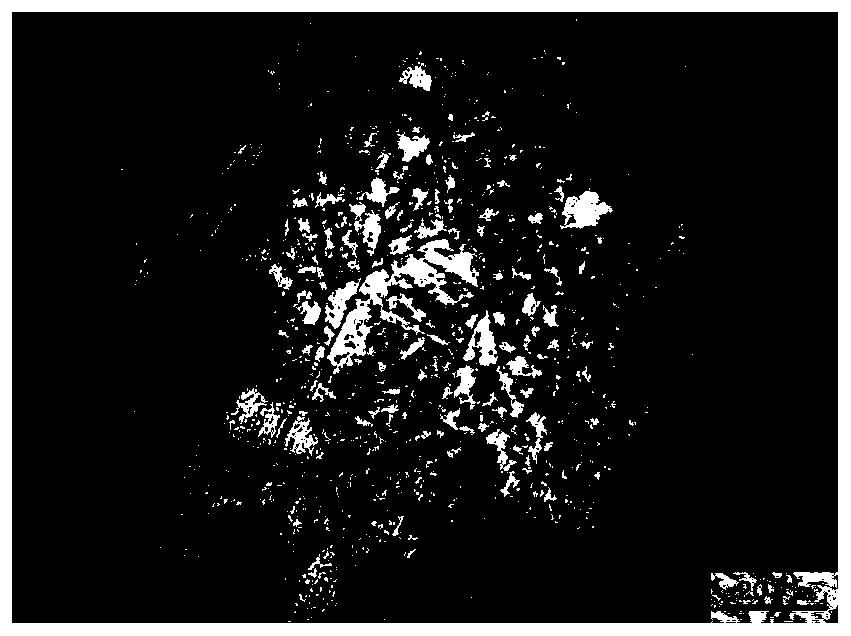

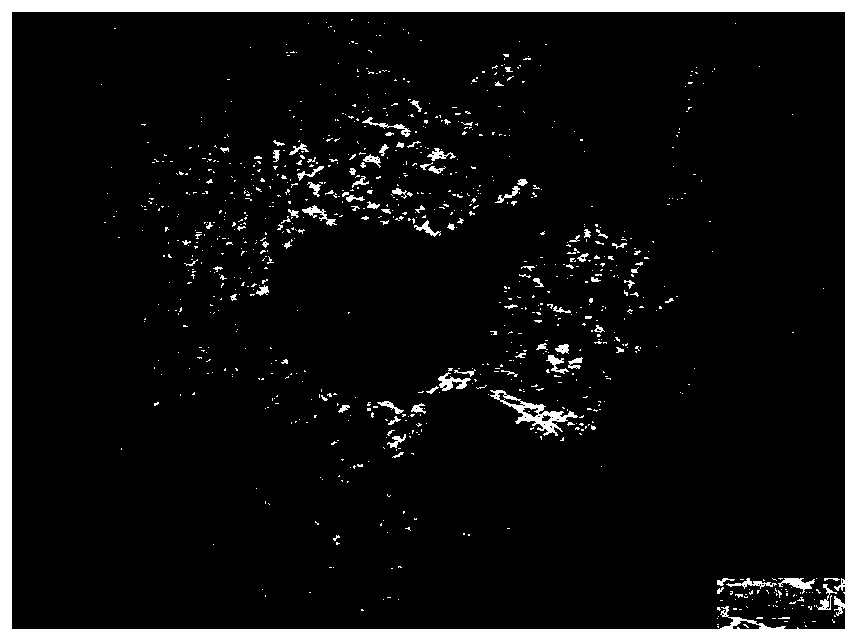

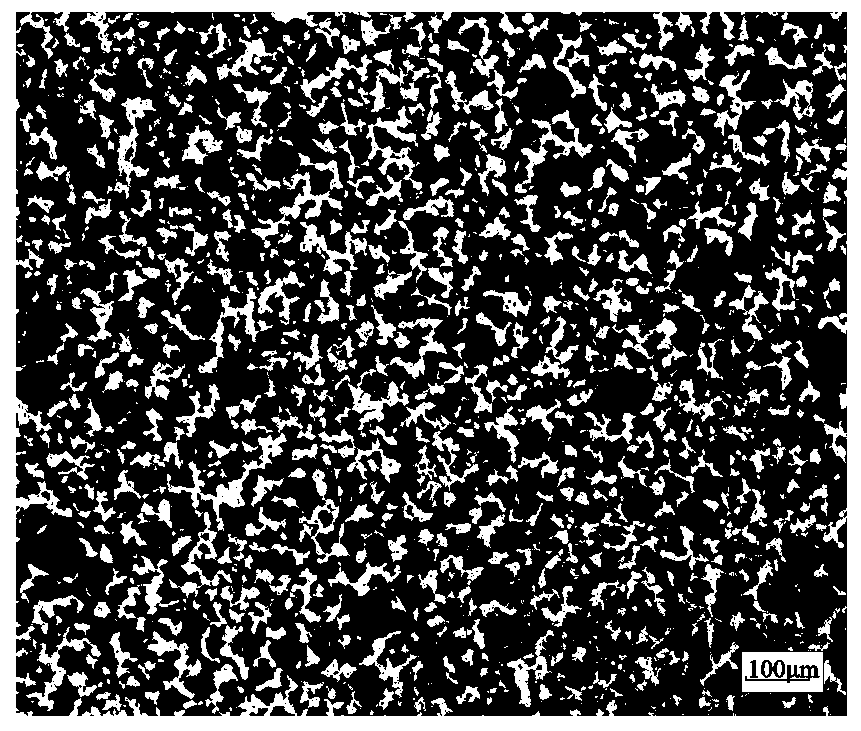

Image

Examples

Embodiment 1

[0028] A rolling process for improving the as-rolled structure of 38CrMoAl steel comprises the following steps:

[0029] (1) Selection of 38CrMoAl steel billet: select the end face 250×280mm continuous casting billet as the 38CrMoAl steel billet;

[0030] (2) Billet heating: raise the temperature of 38CrMoAl steel billet to 1160-1180°C at a rate of 600°C / h, and keep it for more than 1.5h; , to ensure that the 38CrMoAl steel billet is completely evenly fired and then released from the furnace;

[0031] (3) Billet Rough Rolling: The 38CrMoAl steel billet after being released from the furnace is descaled by high-pressure water and then rolled into a Φ135mm process circle by 7 rough rolling racks; Total rolling deformation > 79%;

[0032] (4) Intermediate rolling of steel billet: Φ135mm process circle is carried out intermediate rolling after passing through the heat preservation roller table; the intermediate rolling adopts two-roller continuous rolling, and the process tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com