Phase-change energy-storage material nanocapsule and preparation method thereof

A technology of phase-change energy storage materials and nanocapsules, which is applied in the field of capsules of phase-change energy storage materials and its preparation, can solve the problems of irregular shape of nanocapsules, insufficient emulsion stability, unfavorable practical application, etc., and achieve convenient large-scale Effects of batch preparation, high heat storage/release efficiency, and regular morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] The specific embodiment of the present invention comprises the following steps:

[0039] 1) The oil phase formed by mixing the phase change energy storage material and tetraethyl orthosilicate in a reactor;

[0040] 2) Add water and ethanol to the oil phase described in step 1) to form a water phase, then add an emulsifier (ionic surfactant) and stir, so that the oil phase and the water phase are mixed to form an emulsion, and the oil in the emulsion The phase is dispersed in the water phase to form nano-scale droplets;

[0041]3) adding a basic catalyst to the emulsion to make it react, and obtain nanocapsules of phase-change energy storage materials after the reaction is completed;

[0042] Wherein the mass ratio of the energy storage material to tetraethyl orthosilicate is 1:1 to 5:1, the mass ratio of water to ethanol in the water phase is 0.5:1 to 20:1, and the emulsifier is an ion Type surfactant, its consumption is 0.2~5% of water phase quality, and the consump...

Embodiment 1

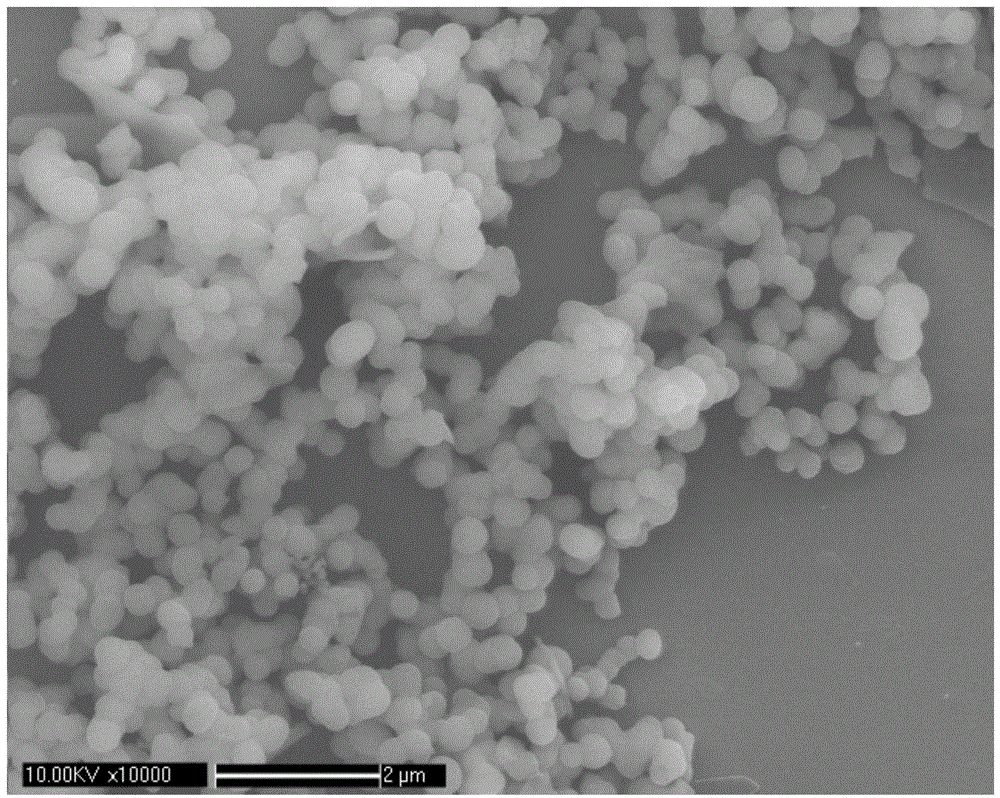

[0049] In a 100mL round bottom flask, add 2g of n-octadecane and 3g of tetraethyl orthosilicate to form an oil phase after miscibility, and then add 25mL of water and 17.7mL of ethanol to the flask in turn, and form a water phase after miscibility. Thereafter, add 0.82g cetyltrimethylammonium bromide, place the flask in a 35°C water bath, and magnetically stir the mixed solution in the flask for 30 minutes at a stirring rate of 1500 rpm to form water Oil-in-lotion. After completing the above steps, add 0.52mL of ammonia water with a mass concentration of 25wt% into the flask, and stir magnetically for 12 hours at 35°C at a stirring rate of 800 rpm. During this process, ethyl orthosilicate undergoes a hydrolysis-condensation reaction , forming a silica shell on the surface of the oil phase droplet. Filter the reacted mixed solution to obtain nanocapsules, wash them with deionized water several times, and then vacuum-dry them at 50°C for 24 hours to obtain nanocapsules with a s...

Embodiment 2

[0051] In a 100mL round bottom flask, add 2g of n-octadecane and 3g of tetraethyl orthosilicate to form an oil phase after miscibility, then add 25mL of water and 17.7mL of ethanol to the flask in turn, and form a water phase after miscibility. Thereafter, add 1.02g cetyltrimethylammonium bromide, place the flask in a 70°C water bath, and magnetically stir the mixed solution in the flask for 30 minutes at a stirring rate of 1500 rpm to form water Oil-in-lotion. After completing the above steps, add 0.52mL of ammonia water with a mass concentration of 25wt% into the flask, and stir magnetically for 6 hours at 70°C at a stirring rate of 800 rpm, during which ethyl orthosilicate undergoes hydrolysis-condensation reaction , forming a silica shell on the surface of the oil phase droplet. Filter the reacted mixed solution to obtain nanocapsules, wash them several times with deionized water, and then vacuum-dry them at 50°C for 24 hours to obtain nanocapsules with n-octadecane struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com