Tabular sodium bismuth titanate/polyvinylidene fluoride composite material and preparation method thereof

A technology of polyvinylidene fluoride and sodium bismuth titanate is applied in the directions of titanate, titanium compound, chemical instruments and methods, etc., to achieve the effect of expanding the scope of application and reducing the probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

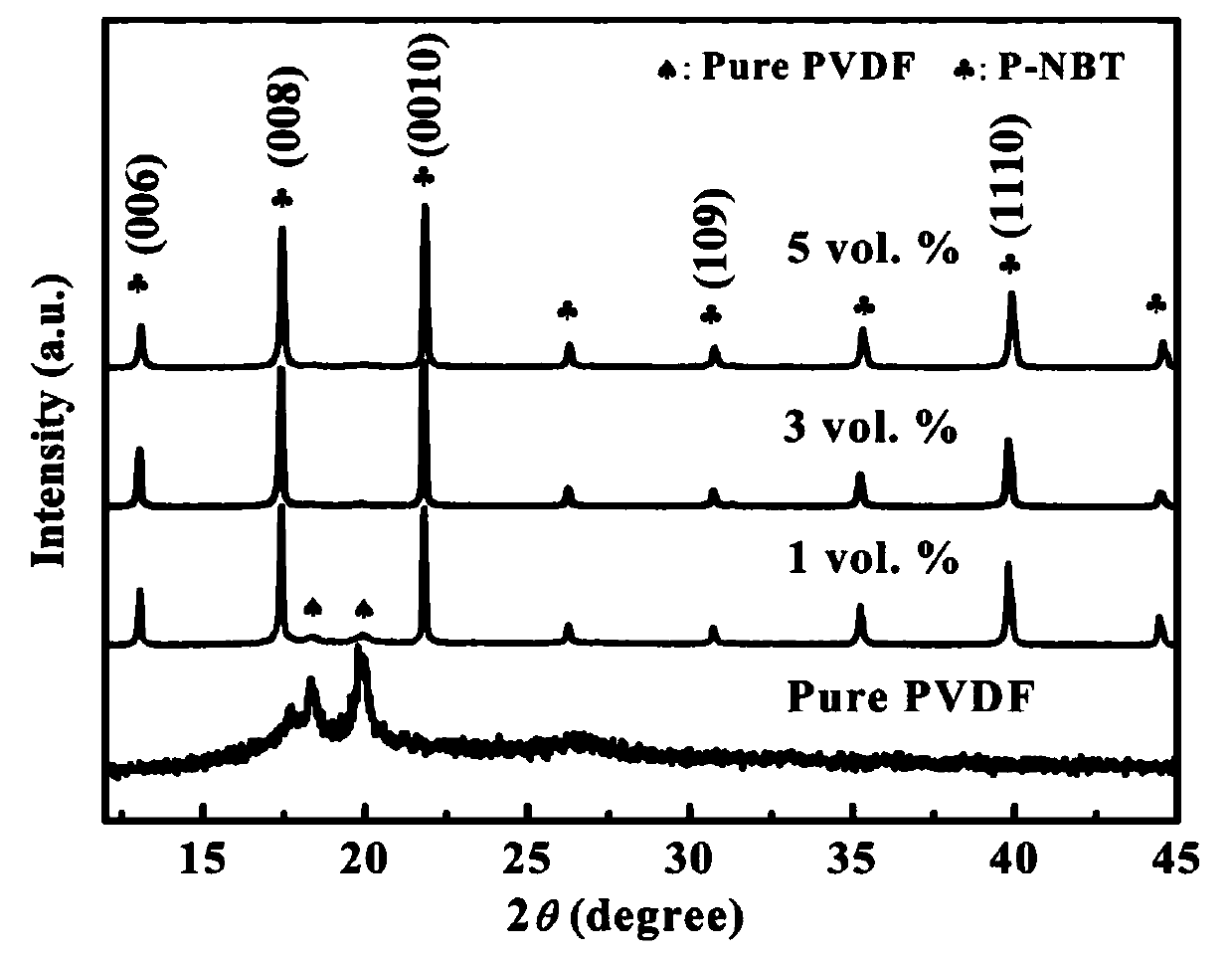

[0037] A preparation method of a textured plate-shaped sodium bismuth titanate / polyvinylidene fluoride composite material comprises the following steps,

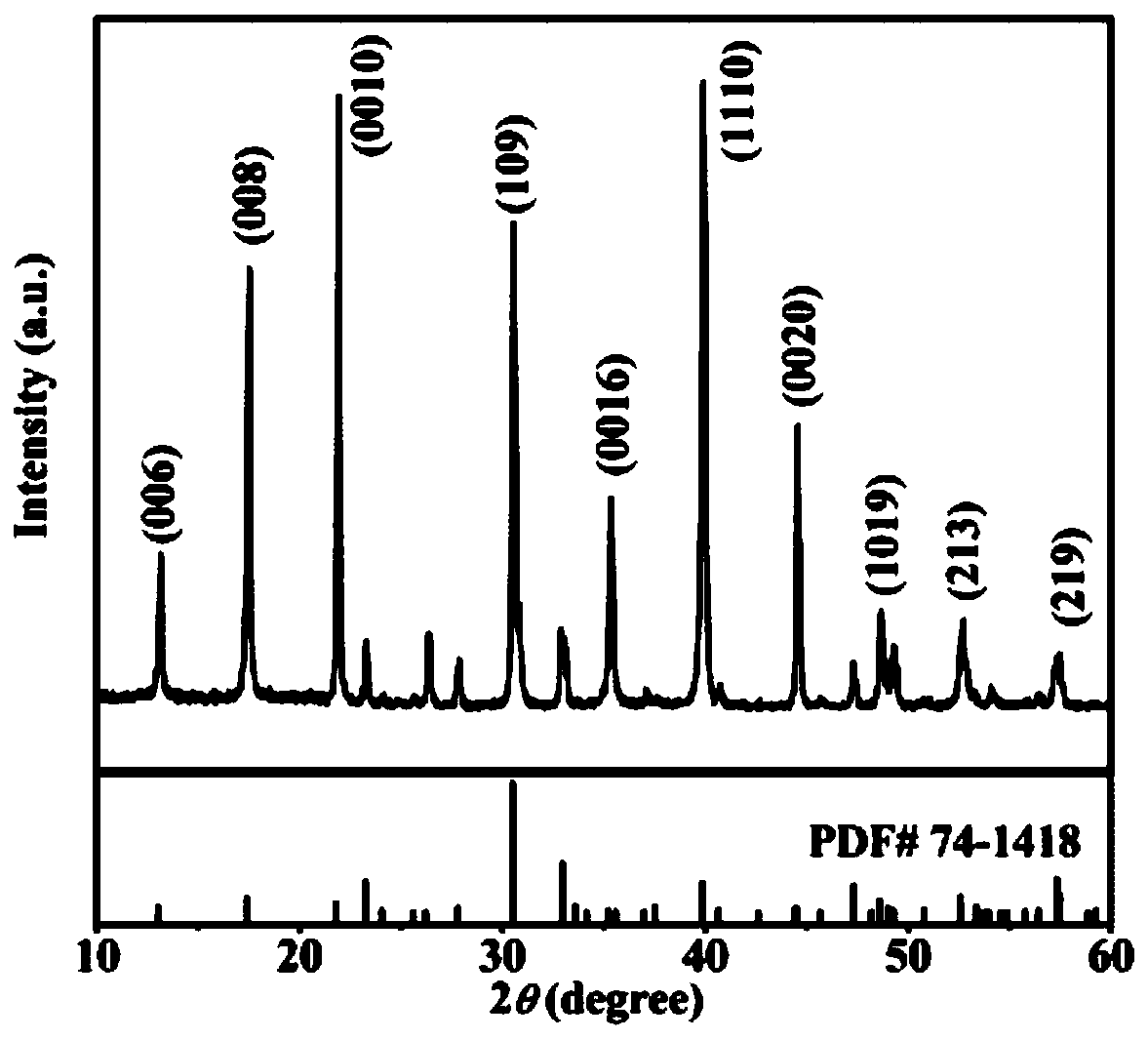

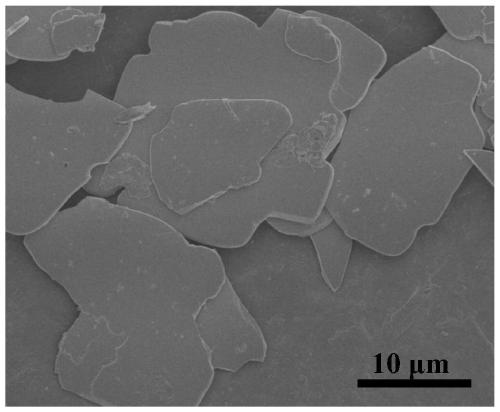

[0038] Step 1, prepare the plate-like Na 0.5 Bi 4.5 Ti 4 o 15 ;

[0039] Weigh Na proportionally 2 CO 3 、 Bi 2o 3 、TiO 2 and NaCl, where Na 2 CO 3 、 Bi 2 o 3 , and TiO 2 The mass ratio of the composed oxide to NaCl ranges from 0.5 to 1; these four kinds of mixtures, zirconia ball stones, and absolute ethanol are added to the ball mill tank according to the mass ratio of 1:2:1, and the absolute ethanol is submerged Na 2 CO 3 、 Bi 2 o 3 、TiO 2 , NaCl, zirconia balls, and spheroidal ink for 4 to 12 hours, and dry; put the dried mixture into a crucible for calcination, the temperature is between 900 and 1100 ° C, and the time is between 2 and 8 hours; the calcined product Grind and sieve into a beaker, wash with 80-90°C deionized water for 7-10 times to remove Cl - Remove it clean, and generally use silver ni...

Embodiment 1

[0052] A preparation method of a textured plate-shaped sodium bismuth titanate / polyvinylidene fluoride composite material comprises the following steps,

[0053] Step 1, prepare the plate-like Na 0.5 Bi 4.5 Ti 4 o 15 ;

[0054] Weigh Na proportionally 2 CO 3 、 Bi 2 o 3 、TiO 2 and NaCl, where Na 2 CO 3 、 Bi 2 o 3 , and TiO 2 The mass ratio of the formed oxide to NaCl is 0.5; these four kinds of mixtures, zirconia ball stone, and absolute ethanol are added to the ball milling tank according to the mass ratio of 1:2:1, and the absolute ethanol has submerged the NaCl at this time. 2 CO 3 、 Bi 2 o 3 、TiO 2 , NaCl and zirconia balls, spheroidal graphite for 4 hours, and dried; put the dried mixture into a crucible for calcination at a temperature of 900°C for 8 hours; grind the calcined product and sieve it into a beaker, Cl was washed seven times with deionized water at 80°C - Remove it clean, and generally use silver nitrate solution to test Cl - Whether it is ...

Embodiment 2

[0063] A preparation method of a textured plate-shaped sodium bismuth titanate / polyvinylidene fluoride composite material comprises the following steps,

[0064] Step 1, prepare the plate-like Na 0.5 Bi 4.5 Ti 4 o 15 ;

[0065] Weigh Na proportionally 2 CO 3 、 Bi 2 o 3 、TiO 2 and NaCl, where Na 2 CO 3 、 Bi 2 o 3 , and TiO 2 The mass ratio of the formed oxide to NaCl is 1; these four kinds of mixtures, zirconia balls, and absolute ethanol are added to the ball mill jar according to the mass ratio of 1:2:1, and the absolute ethanol has submerged the NaCl at this time. 2 CO 3 、 Bi 2 o 3 、TiO 2 , NaCl and zirconia balls, spheroidal graphite for 8 hours, and dried; put the dried mixture into a crucible for calcination at a temperature of 1100°C for 2 hours; grind the calcined product and sieve it into a beaker, Cl was washed 10 times with deionized water at 85°C - Remove it clean, and generally use silver nitrate solution to test Cl - Whether it is removed compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com