Composite phase-change energy storage material, and preparation method and application thereof

A composite phase transition and phase separation technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve problems such as increasing fire prevention, mildew and decay, and achieve long service life, increase service life, and improve the effect of energy storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

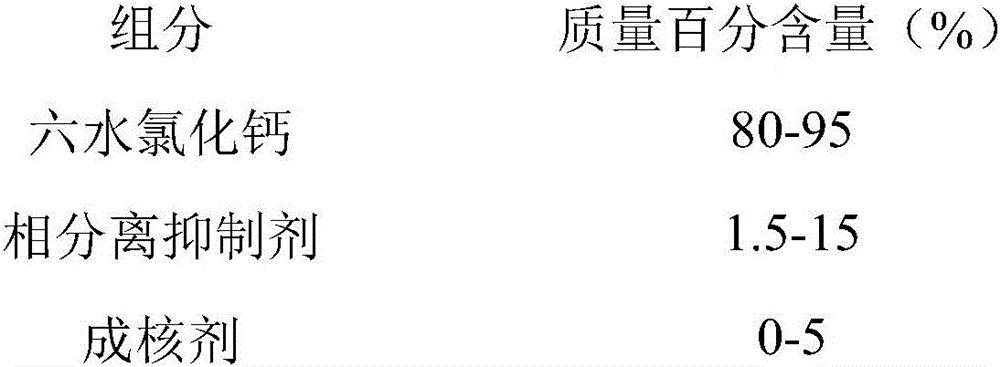

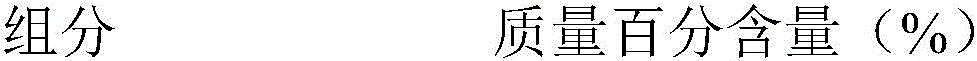

Method used

Image

Examples

Embodiment 1

[0056] Weigh 470g of anhydrous calcium chloride, add it into 470g of water under constant stirring, until it is completely dissolved to form a uniform and transparent solution, add 45g of strontium chloride hexahydrate and stir for 5min, after it is completely dissolved, add 15g of silica airgel to continue Stir for 1 hour to obtain a uniformly dispersed liquid compound salt phase change material.

[0057] The phase change temperature of the prepared phase change energy storage material is 28.5° C., and the phase change latent heat is 178 kJ / kg; after 2000 cycles, the phase change latent heat decays less than 5%.

[0058] Replace the nucleating agent in this example with barium sulfate, replace the phase separation inhibitor with diatomite, attapulgite, sepiolite or zeolite, and keep other preparation conditions unchanged, the phase change of the obtained composite energy storage material The temperature is between 27-29°C, and the phase change enthalpy is between 140-180kJ / kg...

Embodiment 2

[0060] Weigh 400g of anhydrous calcium chloride, add it into 400g of water under constant stirring, until it is completely dissolved to form a uniform and transparent solution, add 25g of strontium chloride hexahydrate + 25g of barium sulfate and stir for 10min to form a suspension, add 0.5g of silicon dioxide Airgel + 49.5g sepiolite powder + 50g diatomite powder + 50g attapulgite powder were continuously stirred for 1 hour to obtain a uniformly dispersed liquid composite salt phase change material.

[0061] The phase change temperature of the prepared phase change energy storage material is 27.8° C., and the phase change latent heat is 143 kJ / kg; after 2000 cycles, the phase change latent heat decays less than 5%.

[0062] The phase separation inhibitor in this example was replaced by a combination of silica airgel, diatomaceous earth, attapulgite, sepiolite and the other four components of zeolite, and the other preparation conditions remained unchanged, and the obtained com...

Embodiment 3

[0064] Weigh 450g of anhydrous calcium chloride, add it into 450g of water under constant stirring, until it is completely dissolved to form a uniform and transparent solution, add 5g of strontium chloride hexahydrate and stir for 5min, after it is completely dissolved, add 95g of diatomite powder and continue stirring After 0.5h, a uniformly dispersed liquid compound salt phase change material was obtained.

[0065] The phase change temperature of the prepared phase change energy storage material is 28.1° C., and the phase change latent heat is 162 kJ / kg; after 2000 cycles, the phase change latent heat decays less than 5%.

[0066] In this example, the nucleating agent is replaced by barium sulfate, the phase separation inhibitor is replaced by silica airgel, attapulgite, sepiolite or zeolite, and other preparation conditions remain unchanged, and the obtained composite energy storage material The phase change temperature is between 27-29°C, and the phase change enthalpy is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com