Method for manufacturing steel thin-wall welding equal-strength components with aluminum or aluminum alloy coatings

A manufacturing method and aluminum alloy technology, which is applied in the field of manufacturing strong parts, can solve problems such as performance deterioration, and achieve the effects of increasing stability, improving hardenability, and improving hardenability and heat strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Clean the surface of the hot-formed steel plate to be welded to remove oil, water stains and other pollutants on the surface to ensure a clean surface.

[0051] The steel plate with aluminum alloy coating of 1.75mm (steel plate composition is shown in Table 1) adopts following process to carry out laser wire filling tailor welding, adopts welding wire described in the present invention (welding wire composition is shown in Table 2), and the spot diameter is the light beam of 1.8mm, welding power 4.5kW, welding speed 80mm / s, reserve 0.3mm for splicing plate gap, 8mm defocus, wire feeding speed 3m / min, welding wire diameter 1.2mm, shielding gas 90% argon + 10% carbon dioxide gas, gas flow rate It is 15L / min.

[0052] After welding, the cross-sectional metallographic observation of the weld seam shows that the macroscopic appearance of the weld seam is excellent, and there is no obvious spatter.

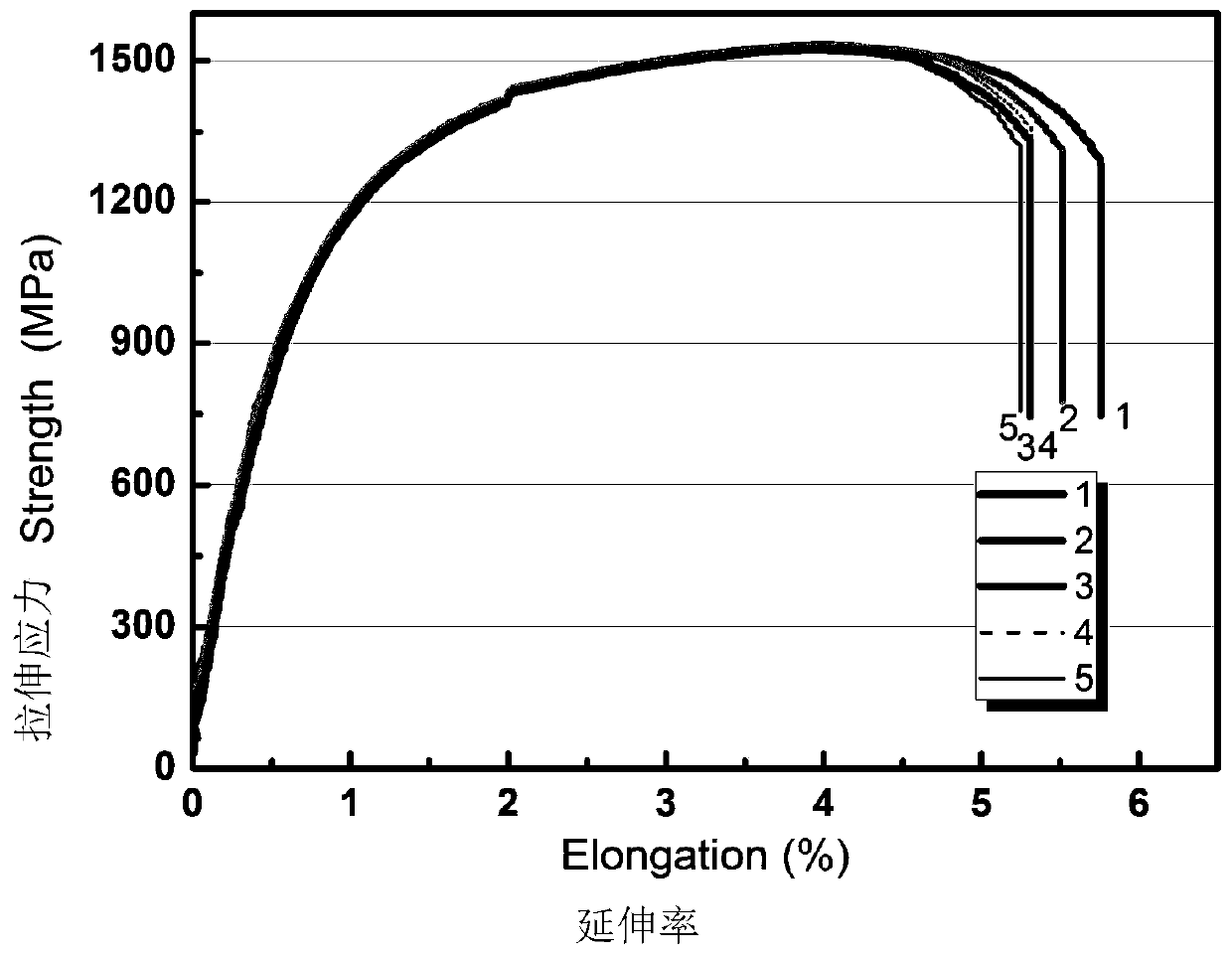

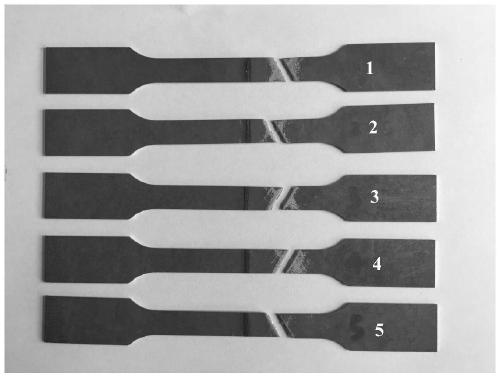

[0053] After welding, hot stamping and quenching is carried out on the tail...

Embodiment 2

[0056] Clean the surface of the hot-formed steel plate to be welded to remove oil, water stains and other pollutants on the surface to ensure a clean surface.

[0057] The steel plate with aluminum alloy coating of 1.8mm (steel plate composition is shown in Table 1) adopts following process to carry out laser filler wire tailor welding, adopts welding wire described in the present invention (welding wire composition is shown in Table 2), and the spot diameter is the light beam of 2.0mm, welding power 6kW, welding speed 80mm / s, reserve 0.5mm for splicing plate gap, 10mm defocus, wire feeding speed 4m / min, welding wire diameter 1.2mm, shielding gas 80% argon + 20% carbon dioxide gas, gas flow rate is 15L / min.

[0058] After welding, the cross-sectional metallographic observation of the weld seam shows that the macroscopic appearance of the weld seam is excellent, and there is no obvious spatter.

[0059] After welding, the same hot stamping process as in Example 1 is used to ca...

Embodiment 3

[0061] Clean the surface of the hot-formed steel plate to be welded to remove oil, water stains and other pollutants on the surface to ensure a clean surface.

[0062] The steel plate with aluminum alloy coating of 1.5mm (steel plate composition is shown in Table 1) adopts following process to carry out laser filler wire tailor welding, adopts welding wire described in the present invention (welding wire composition is shown in Table 2), and laser spot diameter is the light beam of 1.8mm, welding The power is 5kW, the welding speed is 80mm / s, the splicing plate gap is reserved for 0.4mm, the defocus is 8mm, the wire feeding speed is 3m / min, the welding wire diameter is 1.2mm, the shielding gas is 60% argon + 40% carbon dioxide gas, the gas flow rate It is 15L / min.

[0063] After welding, the cross-sectional metallographic observation of the weld seam shows that the macroscopic appearance of the weld seam is excellent, and there is no obvious spatter.

[0064] After welding, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com