Laser welding method for cold-rolled steel plates for car and welding joint thereof

A cold-rolled steel plate and laser welding technology, which is applied to laser welding equipment, welding media, welding equipment, etc., can solve problems such as excessive alloying of welds, waste of resources, and increased production costs, and achieve a reduction in the temperature range where high temperatures exist, The effect of reducing the degree of alloying and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

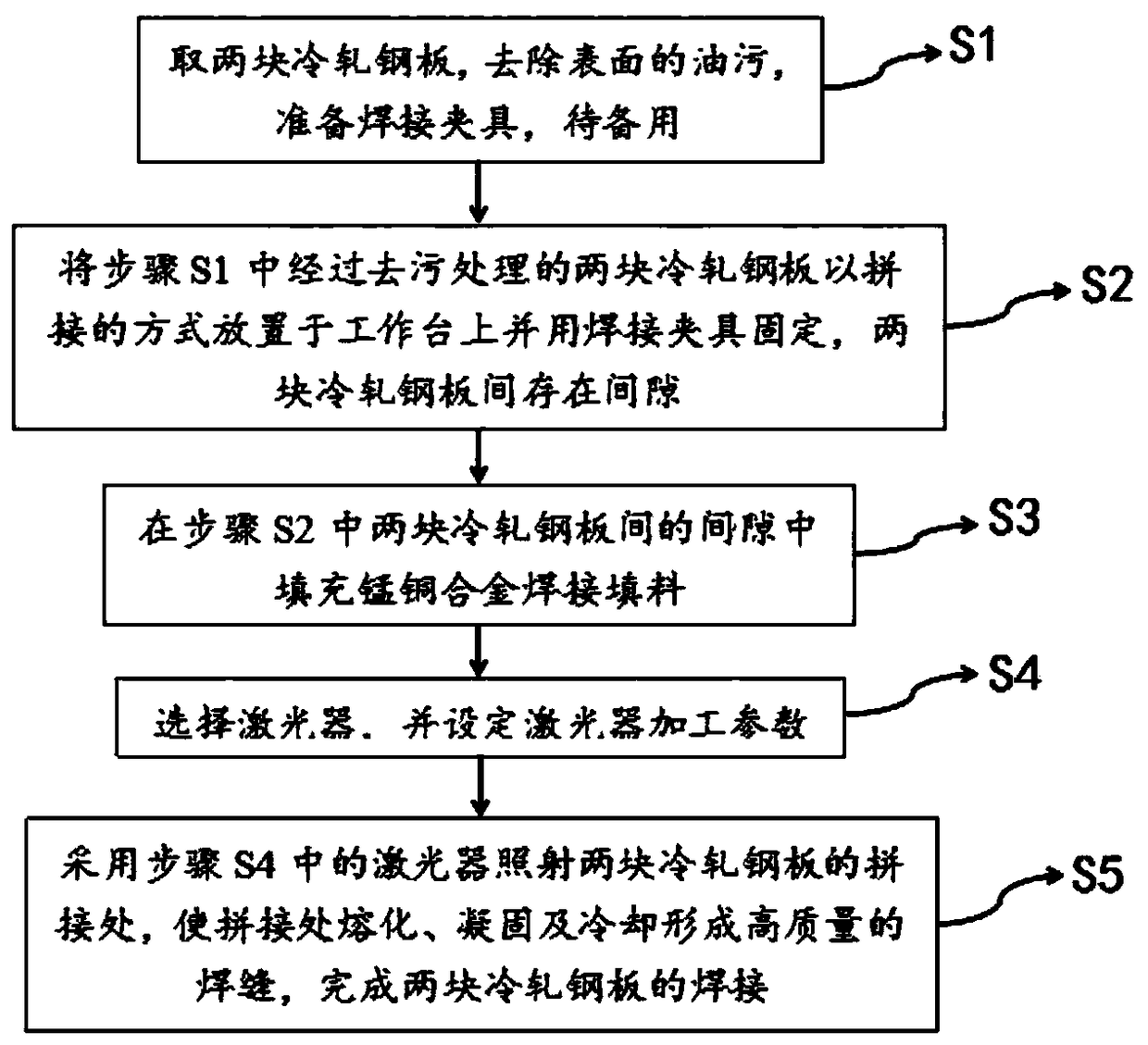

[0046] A laser welding method for cold-rolled steel sheets for automobiles, comprising the steps of:

[0047] S1. Take two cold-rolled steel plates with a thickness of 1.5 mm. The base metal structure is lath martensite. At least one cold-rolled steel plate is a hot-formed steel plate with an Al-Si coating. Use acetone to remove the oil on the surface of the hot-formed steel plate , prepare the welding jig and wait for it to be used.

[0048] S2. Place the two cold-rolled steel plates that have been decontaminated in step S1 on the workbench in a spliced manner and fix them with welding fixtures. There is a gap between the two cold-rolled steel plates, and the gap distance is 0.02mm.

[0049] S3. In step S2, manganese-copper alloy foil is filled in the gap between the two cold-rolled steel plates, wherein the selected manganese-copper alloy foil has a manganese element content of 5%, a copper element content of 95%, and a thickness of 0.02 mm;

[0050] S4. Use the IPG-6kW f...

Embodiment 2

[0054] A laser welding method for cold-rolled steel sheets for automobiles, comprising the steps of:

[0055] S1. Take two cold-rolled steel plates with a thickness of 1.5 mm. The base metal structure is lath martensite. At least one cold-rolled steel plate is a hot-formed steel plate with an Al-Si coating. Use acetone to remove the surface of the hot-formed steel plate. Oil stains, prepare the welding jig and wait for it to be used.

[0056] S2. Place the two cold-rolled steel plates that have been decontaminated in step S1 on the workbench in a spliced manner and fix them with welding fixtures. There is a gap between the two cold-rolled steel plates, and the gap distance is 0.06mm.

[0057] S3, filling the gap between the two cold-rolled steel plates in step S2 with manganese-copper alloy wire, wherein the selected manganese-copper alloy wire has a manganese element content of 10%, a copper element content of 90%, and a thickness of 0.06 mm;

[0058] S4. Use the IPG-6kW f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com