Rolling method capable of reducing as-rolled hardness of 42CrMo steel

A hardness, steel rolling technology, applied in the field of steel rolling, can solve problems such as easy occurrence of shear cracks, and achieve the effect of grain refinement and improvement of organizational uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] A kind of rolling method that reduces 42CrMo steel as-rolled hardness, comprises the following steps:

[0028] (1) Heat treatment of the blank of 42CrMo steel

[0029] (11) The billet of 42CrMo steel (250×280mm continuous casting billet) was heated from room temperature to 1180°C at a rate of 600°C / h and kept for 1.5h;

[0030] (12) The blank of 42CrMo steel in the step (1) is adjusted to 1160 DEG C with the speed of 150 DEG C / h, and after uniform temperature 1h, it is released from the furnace to obtain the blank of 42CrMo steel after treatment;

[0031] (2) Rolled billet

[0032] (21) Rough rolling

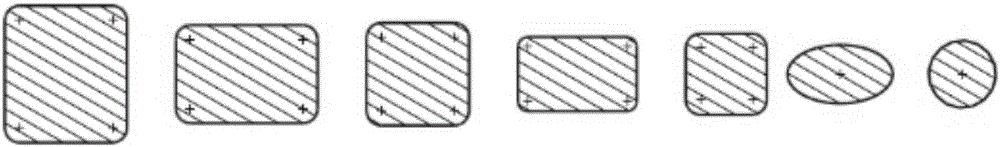

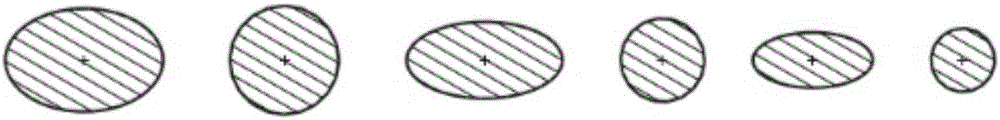

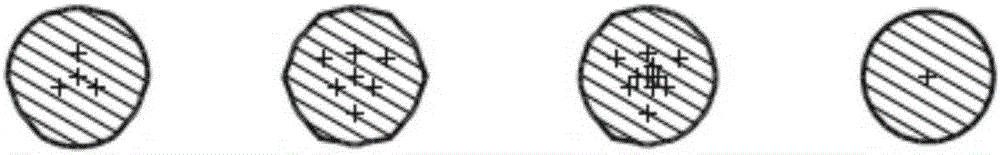

[0033] like figure 1 Shown, the billet of the processed 42CrMo steel that step (12) obtains is passed through seven stands of two-roll rolling mill continuous rolling ( figure 1 Each figure in the figure represents the cross-sectional schematic diagram of the billet after passing through a two-roll mill), the rolled 42CrMo steel material is a rough rolling preparation...

specific Embodiment 2

[0042] A kind of rolling method that reduces 42CrMo steel as-rolled hardness, comprises the following steps:

[0043] (1) Heat treatment of the blank of 42CrMo steel

[0044] (11) Heat the blank of 42CrMo steel from room temperature to 1160°C at a rate of 600°C / h and keep it warm for 2h;

[0045] (12) adjusting the temperature of the blank of 42CrMo steel in the step (1) to 1150° C. at a speed of 150° C. / h, taking out the furnace after 1 hour of uniform temperature, and obtaining the blank of 42CrMo steel after treatment;

[0046] (2) Rolled billet

[0047] (21) Rough rolling

[0048] The billet of the processed 42CrMo steel that step (12) obtains is adopted two-roller continuous rolling rolling, and the 42CrMo steel stock of rolling is rough rolling preparatory round, will be the billet of rough rolling preparatory round 42CrMo steel through standing in 20 seconds After rewarming, the temperature is controlled at 1000°C;

[0049] (22) Intermediate rolling

[0050] The bi...

specific Embodiment 3

[0057] A kind of rolling method that reduces 42CrMo steel as-rolled hardness, comprises the following steps:

[0058] (1) Heat treatment of the blank of 42CrMo steel

[0059] (11) Heat the blank of 42CrMo steel from room temperature to 1200°C at a rate of 600°C / h and keep it warm for 1h;

[0060] (12) The blank of 42CrMo steel in the step (1) is adjusted to 1180 DEG C with the speed of 150 DEG C / h, and after uniform temperature 1h, it is released from the furnace, so as to obtain the blank of 42CrMo steel after treatment;

[0061] (2) Rolled billet

[0062] (21) Rough rolling

[0063] The billet of the processed 42CrMo steel that step (12) obtains is adopted two-roller continuous rolling rolling, and the 42CrMo steel stock of rolling is rough rolling preparatory round, will be the billet of rough rolling preparatory round 42CrMo steel through 40 seconds standstill After rewarming, the temperature is controlled at 1050°C;

[0064] (22) Intermediate rolling

[0065]The bill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com