A kind of uv-cured electrospun colored micro-nano fiber stranded wire and preparation method thereof

A technology of micro-nano fiber and color, applied in the preparation of spinning solution, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of single white color, achieve good flexibility, and the phenomenon of oxygen inhibition is not obvious , Rich and full color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of the colored micro-nano fiber stranded wire of UV curing electrospinning, comprises the following steps:

[0037] 1) Configure the spinning precursor solution: add 8 grams of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)) and 0.4 grams of liquid photoinitiator (photoinitiator 1173, 2-hydroxy- 2-Methyl-1-phenyl-1-acetone, Aldrich) was carried out shading stirring with a magnetic stirrer, heated in a 40-degree water bath, and stirred for 2 hours to fully mix the photoinitiator and urethane acrylate, and stand at room temperature In 2 days, a certain degree of prepolymerization occurred to obtain the spinning precursor solution;

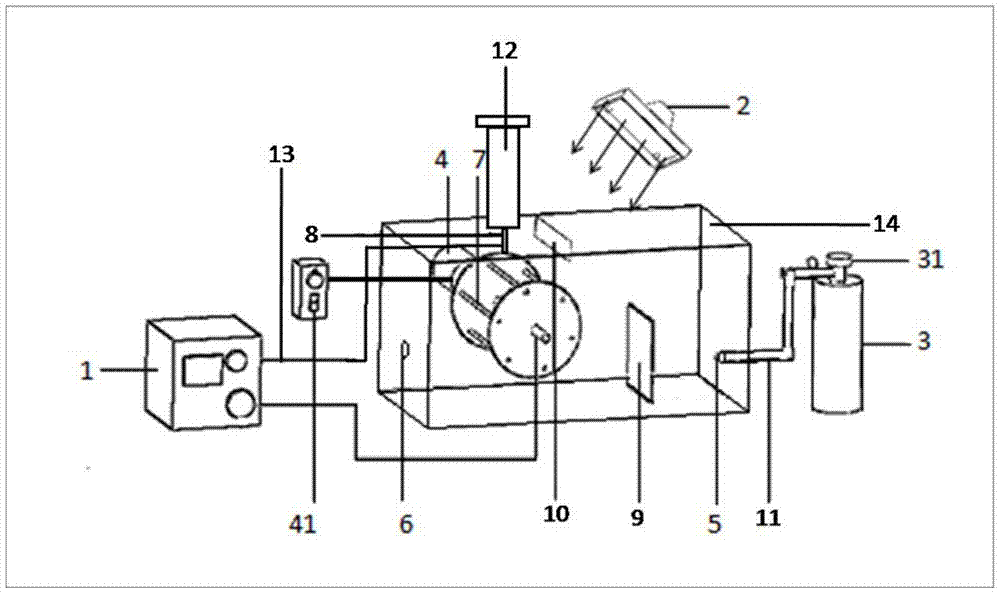

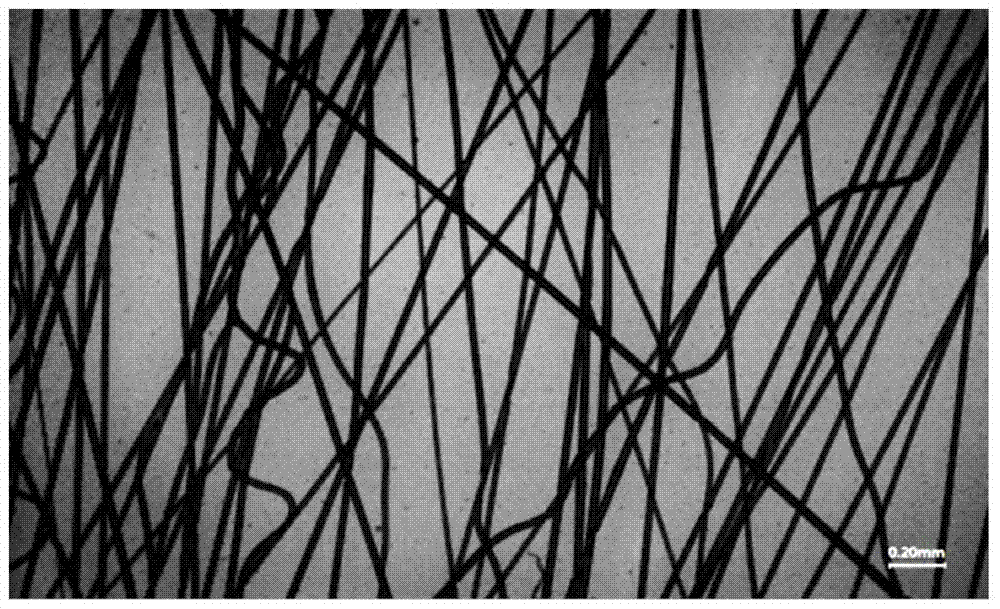

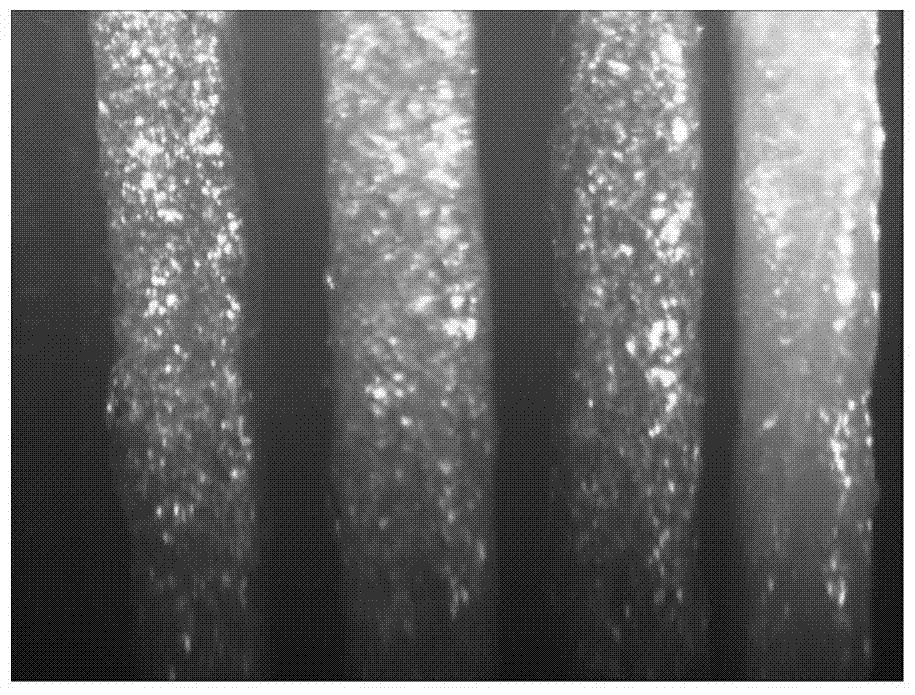

[0038] (2) Preparation of stranded wire: Pour the prepared spinning precursor solution into an aluminum spinneret with an inner diameter of 1.2 cm, the tip of the spinneret is 2 mm in size, and nitrogen is introduced into the airtight box at a nitrogen flow rate of 3 Cubic millimete...

Embodiment 2

[0043] Embodiment 2 white control group

[0044] A kind of preparation method of the colored micro-nano fiber stranded wire of UV curing electrospinning, comprises the following steps:

[0045] 1) Configure the spinning precursor solution: add 8 grams of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)) and 0.4 grams of liquid photoinitiator (photoinitiator 1173, 2-hydroxy- 2-Methyl-1-phenyl-1-acetone, Aldrich) carry out light-shielding stirring with a magnetic stirrer, adopt 40 degree of water bath heating, stir for 2 hours, make photoinitiator and polyurethane acrylate fully mix, in above-mentioned Erlenmeyer flask Then add 1.0 gram of red phototherapy glue (Maychao, A011) and stir for 4 hours with a magnetic stirrer in shading, so that the photoinitiator and urethane acrylate are fully mixed, and left to stand at room temperature for 2 days, a certain degree of prepolymerization occurs, and the obtained Spinning precursor;

[0046] (2) Prepar...

Embodiment 3

[0050] A kind of preparation method of the colored micro-nano fiber stranded wire of UV curing electrospinning, it is characterized in that, comprises the following steps:

[0051] (1) Configure the spinning precursor solution: add 8 grams of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)) and 0.8 grams of solid-state photoinitiator (184,1-hydroxy- Cyclohexyl-phenyl ketone, Aldrich) carried out shading stirring with a magnetic stirrer, heated in a 44-degree water bath, stirred for 3 hours, and then added 1.0 gram of red phototherapy glue (Maychao, A011) in the above-mentioned Erlenmeyer flask with a magnetic stirrer Shade and stir for 4 hours to fully mix the photoinitiator and urethane acrylate, and let it stand at room temperature for 1 day to mix the phototherapy glue and DR-U301 evenly and prepolymerize to a certain extent to obtain the spinning precursor;

[0052] (2) Preparation of stranded wire: Pour the prepared spinning precursor soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com