A multi-channel swirling automatic liquid control device

A multi-channel, automatic technology, applied in wellbore/well valve device, production fluid, wellbore/well components, etc., can solve the problems of insignificant phase separation effect, insufficient fluid swirl, etc., to achieve phase separation The effect is obvious, the integrity is high, and the effect of increasing the pressure drop ratio along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a clearer understanding of the present invention, the present invention is now described with reference to the accompanying drawings, and the protection scope of the present invention is not limited to the following:

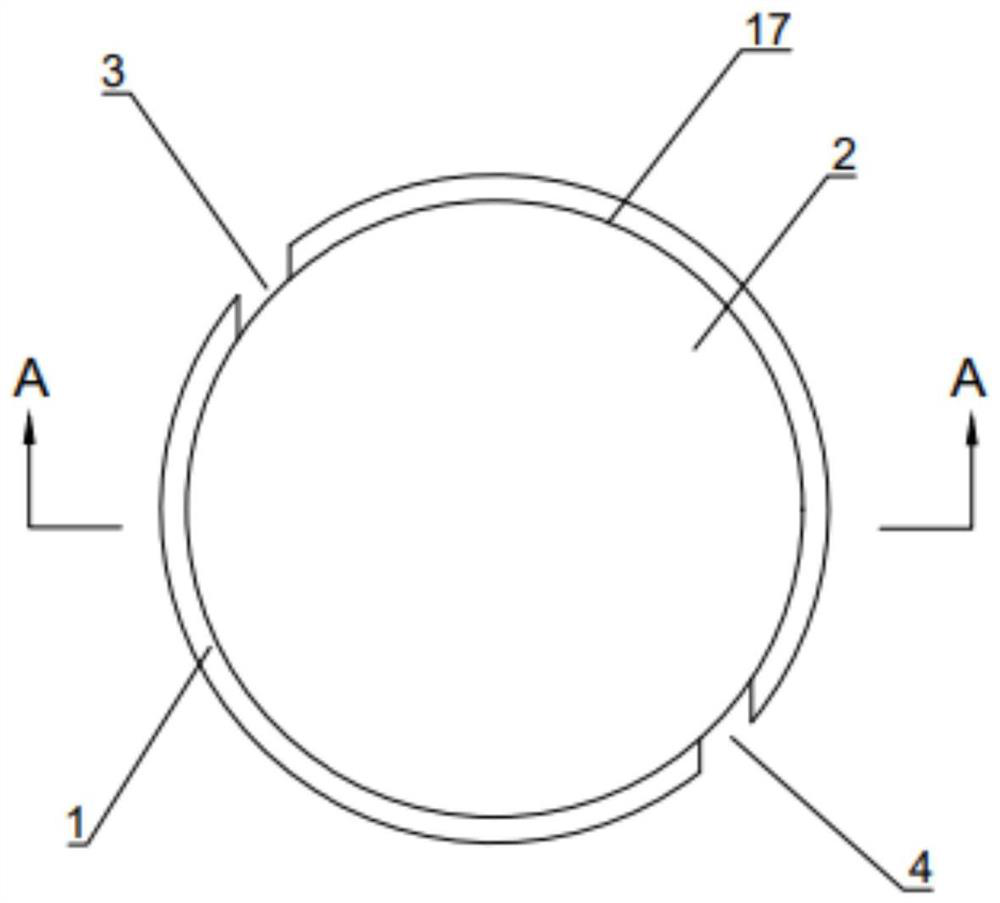

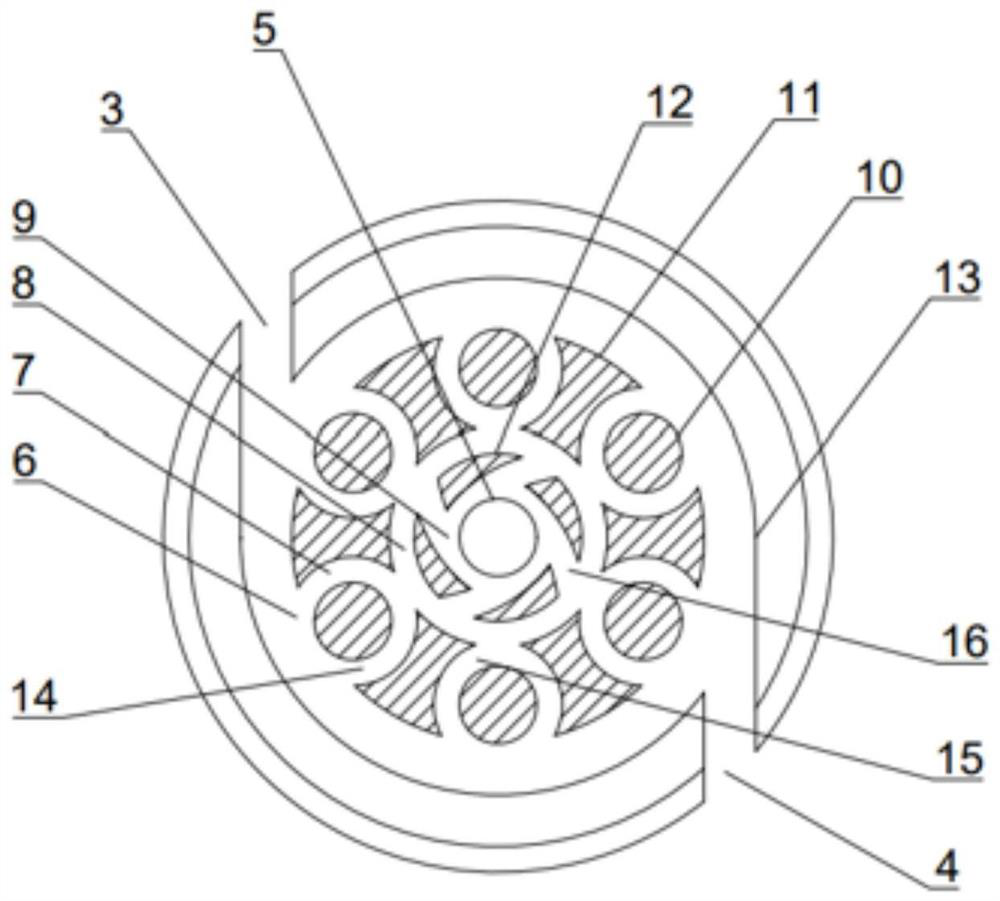

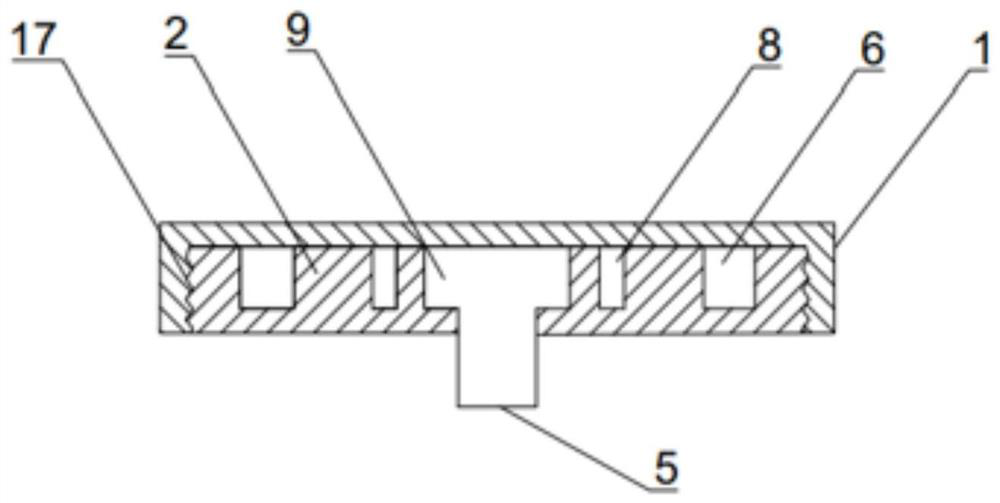

[0024] like figure 1 , figure 2 As shown, a multi-channel swirl automatic liquid control device includes a valve cover 1 and a valve body 2, and the valve body 2 includes a liquid inlet A3, a liquid inlet B4, a liquid outlet 5 and a multi-stage flow channel; The stage flow channel includes an outer swirl flow channel 6, a tangential flow channel 7, an intermediate flow channel 8 and an inner swirl flow channel 9; the valve body 2 connects the liquid inlet A3 and the liquid inlet B4 through the multi-stage flow channel in a groove type. Connecting with the liquid outlet 5 , the valve cover 1 and the valve body 2 are connected by connecting threads 17 .

[0025] like figure 2 As shown, the liquid inlet A3 and the liquid inlet B4 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com