W/O emulsion demulsification method

An emulsion and demulsification technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of difficult recovery, large equipment volume and high cost, and achieve wide application prospects, large processing capacity, and processing costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

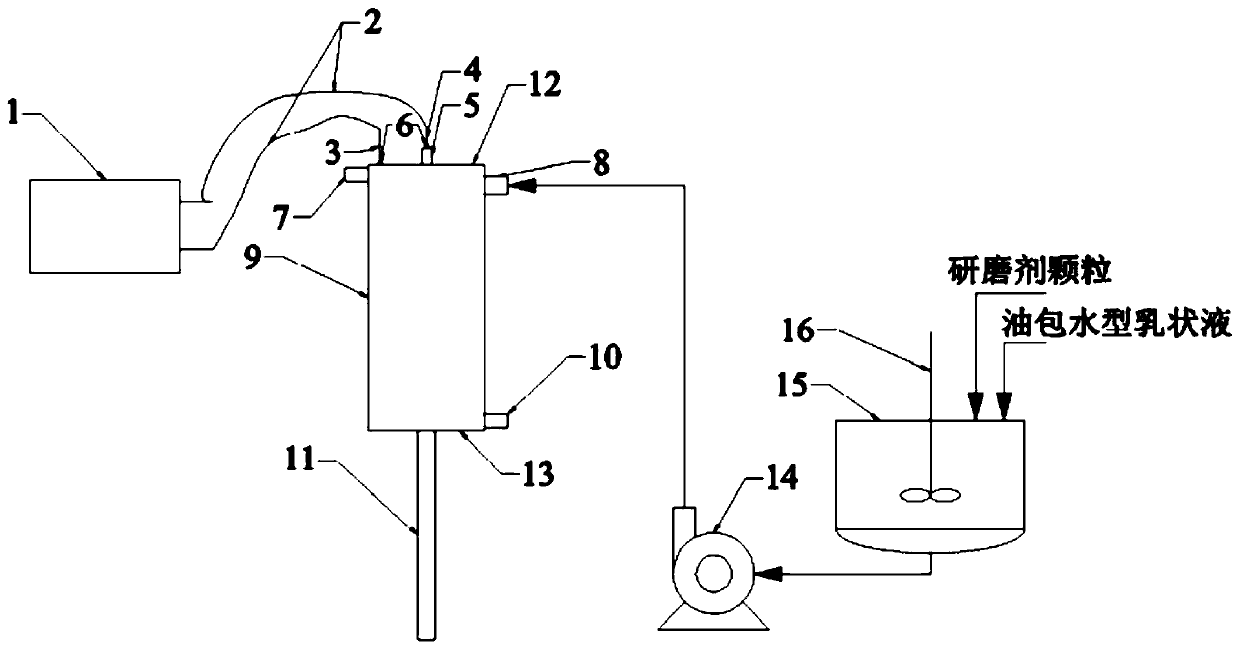

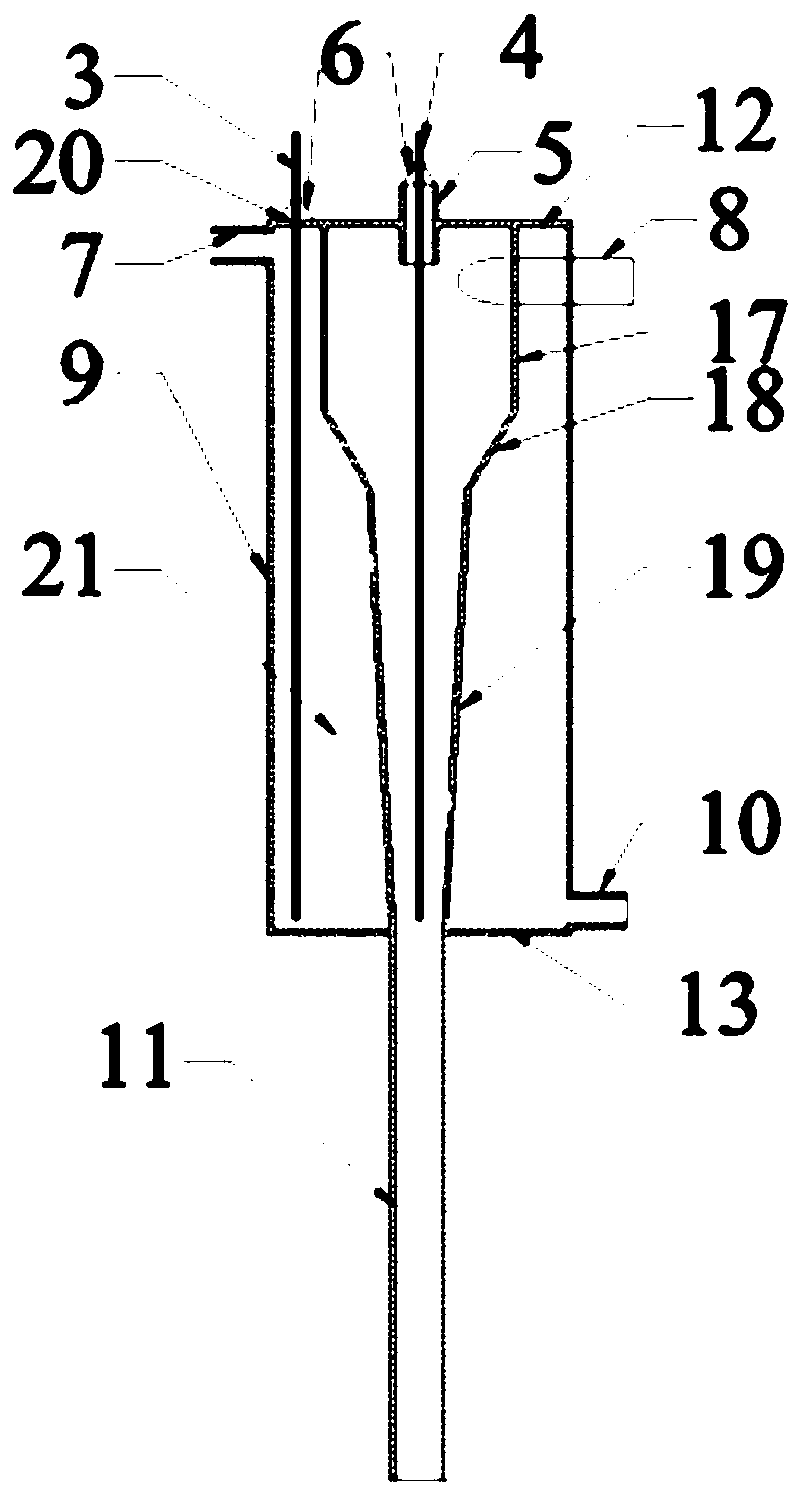

[0035] This embodiment discloses a demulsification device for the demulsification method of a W / O emulsion, such as figure 1 As shown, during use: put the abrasive particles and the W / O emulsion in the storage tank 15 before starting, and stir and mix them evenly with the agitator 16 . Connect the positive pole and the negative pole of the power generator 1 to the first insulated electrode 3 and the second insulated electrode 4 respectively through the insulated wire 2, insert the first insulated electrode 3 into the annular gap 21 through the socket 20 to the bottom end of the annular gap 21, and The bracket 6 is fixed, and the second insulated electrode 4 is inserted into the cyclone device through the oil outlet 5 to the bottom of the small cone section 19 and fixed by the bracket 6 . Close the valve of the liquid outlet 10 , inject the electrolyte solution into the annular gap 21 from the liquid inlet 7 and fill the annular gap 21 . The demulsification starts, the power g...

Embodiment 2

[0037] This embodiment discloses a method for demulsifying a W / O emulsion. The demulsification operation steps for a W / O emulsion include:

[0038] (1) Use a stirrer to evenly distribute the abrasive particles in the W / O emulsion, wherein the speed of the stirrer is 50-100r / min, and the W / O emulsion is stirred at a speed of 50-100r / min, On the one hand, in order to avoid the further emulsification effect of the W / O emulsion, on the other hand, the abrasive particles can be fully and evenly distributed in the W / O emulsion, and the abrasive particles are particles of hydrophilic and oleophobic materials. The hydrophilic and oleophobic material is silica material or zeolite material. The abrasive particles of this material can promote the full phase separation of oil and water; the particle size of the abrasive particles is 0.5mm-8mm, and the abrasive particles are The diameter of the abrasive particle should not be too large or too small. If the particle size of the abrasive par...

Embodiment 3

[0043]This example discloses a method for demulsifying a W / O emulsion based on Example 1 or Example 2. The specific steps are: abrasive particles: silicon dioxide particles; the W / O emulsion is : The organic phase is kerosene 2000mL + tributyl phosphate 3000mL, the internal water phase is wet-process phosphoric acid 1000mL, the volume ratio of oil and water is 5:1; the feed volume flow rate of W / O emulsion is 14.5L / min; NaCl solution; pulse electric field strength and frequency are 5kV / cm and 700Hz, respectively. The demulsification experiment was carried out under the above experimental conditions. After the demulsification, the oil-water two phases were respectively connected to a measuring cylinder through the hoses connected to the oil outlet and the water outlet, and the volumes of the oil-water two phases were read. The experimental results are shown in the table below. It can be seen from the table that the demulsification rate can reach 97.3%. Here, the demulsification...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com