Heavy oil full-fraction hydrotreatment method and system thereof

A hydrogenation treatment and fractionation technology, which is applied in the field of coal chemical industry, can solve the problems of resource waste and low light oil rate, and achieve the effects of stable operation, high oil yield and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

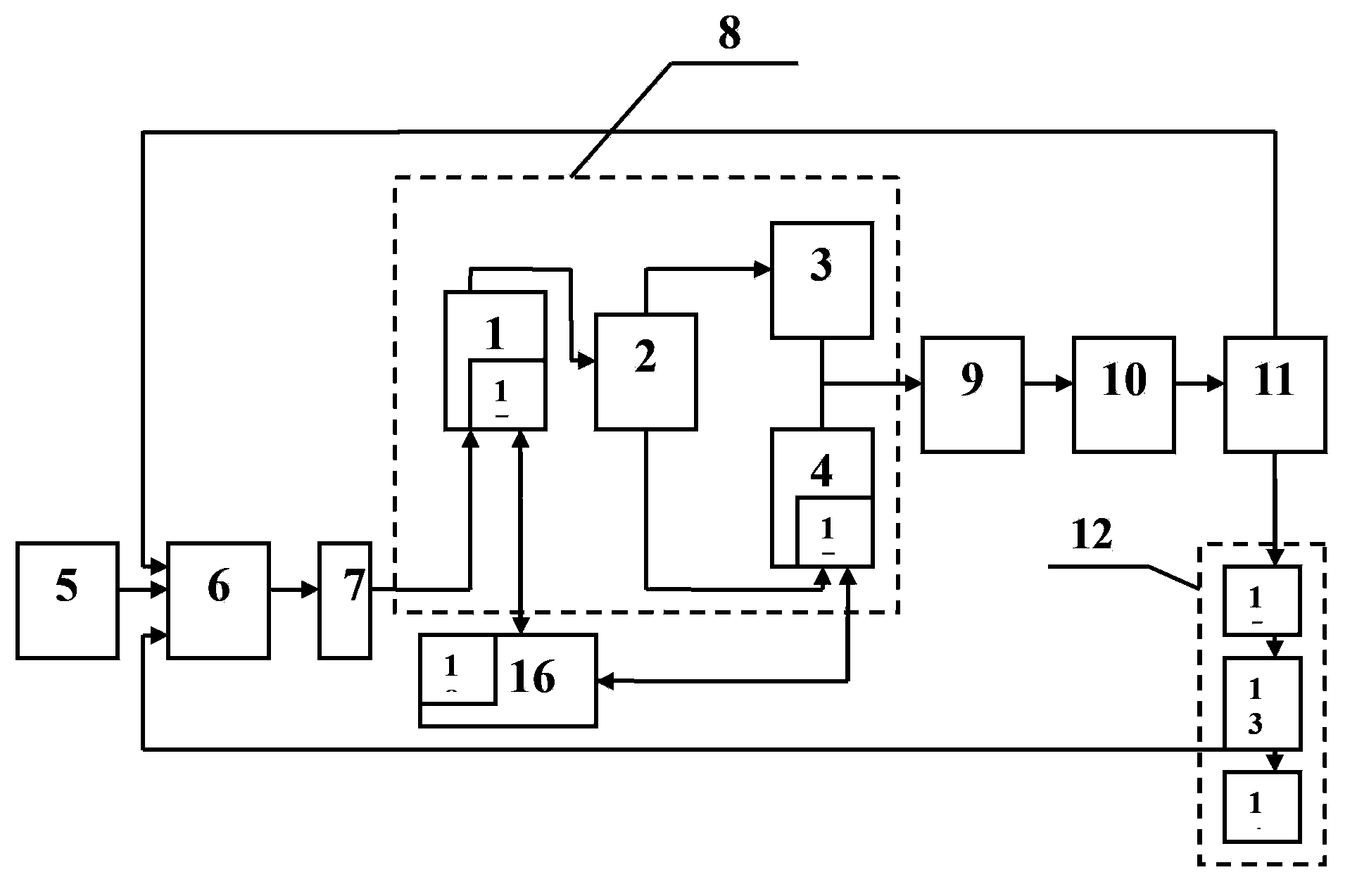

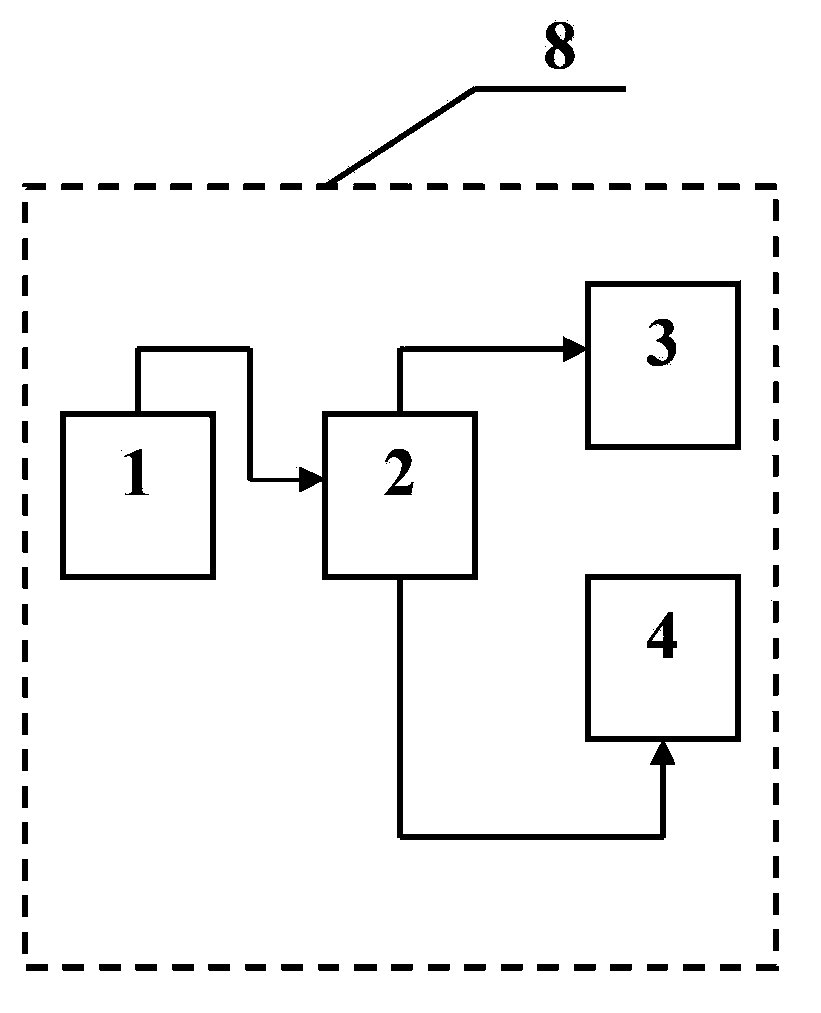

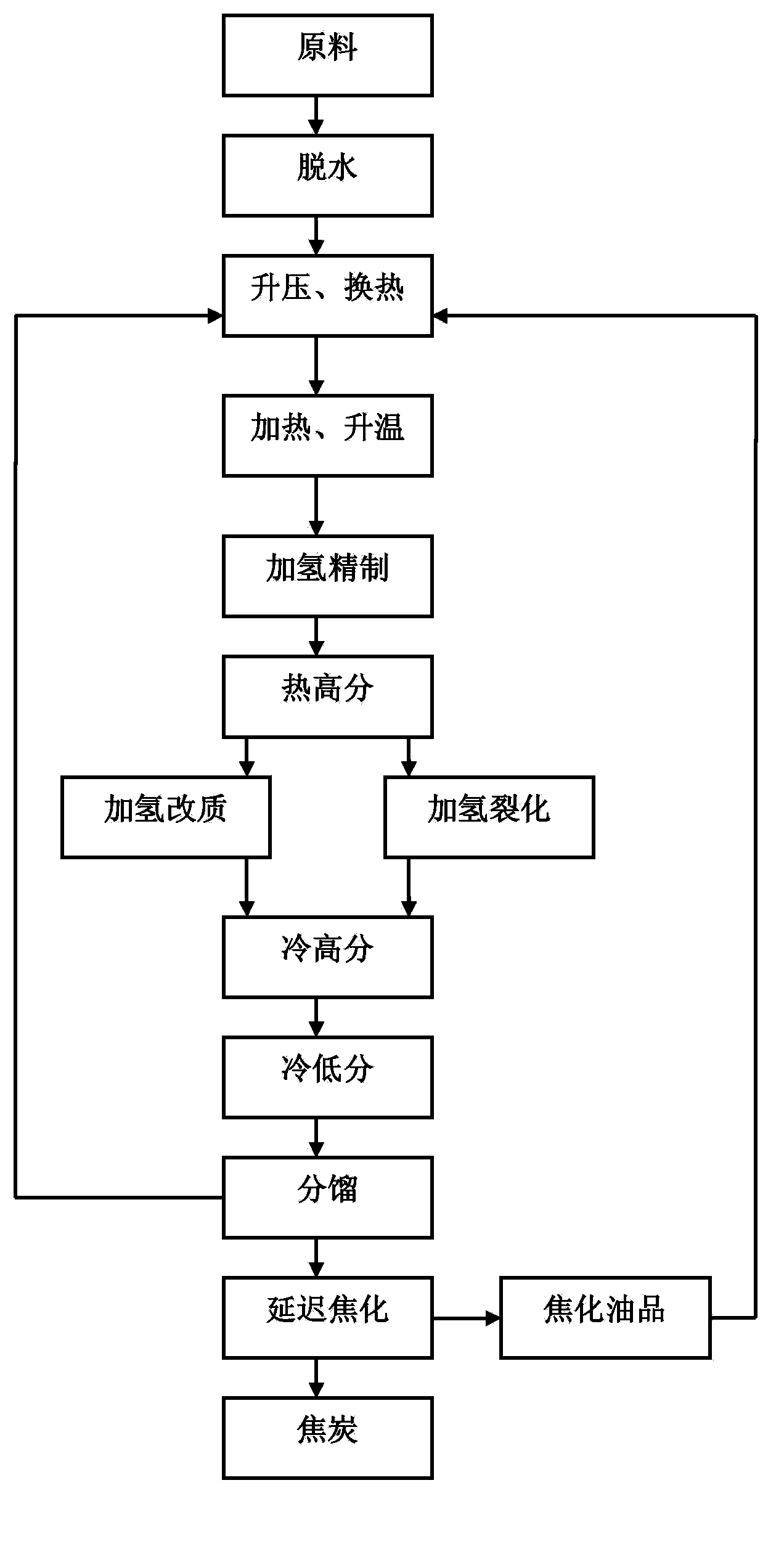

[0031] Embodiment 1: as figure 1 , figure 2 , image 3 As shown: the heavy component raw oil comes from outside the boundary area, and after exchanging heat with the system heat exchanger, the temperature is raised to 150-180°C, and then enters the vacuum dehydration tower 5 to remove moisture. The dehydrated raw material oil is boosted by the feed pump 6, and after heat exchange, it is mixed with hydrogen and enters the raw material heating furnace 7. The raw material oil is heated by the heating furnace 7 to 260-300°C and then enters the hydrotreating device 8 for hydrogenation. It specifically includes: the raw material oil enters the fluidized bed hydrofining reactor 1 (bottom-in and top-out type), and hydrofining reaction occurs under the action of high temperature, high pressure, hydrogenation and catalyst. The reaction temperature is controlled at 360-385°C, the reaction pressure is controlled at about 15-18MPa, the hydrogen-oil ratio is controlled at 800:1, and the ...

Embodiment 2

[0036] Embodiment 2: as figure 1 , figure 2 , image 3 As shown: the heavy component raw oil comes from outside the boundary area, and after exchanging heat with the system heat exchanger, the temperature is raised to 150-180°C, and then enters the vacuum dehydration tower 5 to remove moisture. The dehydrated raw material oil is boosted by the feed pump 6, and after heat exchange, it is mixed with hydrogen and enters the raw material heating furnace 7. The raw material oil is heated by the heating furnace 7 to 260-300°C and then enters the hydrotreating device 8 for hydrogenation. It specifically includes: the raw material oil enters the fluidized bed hydrofining reactor 1 (bottom-in and top-out type), and hydrofining reaction occurs under the action of high temperature, high pressure, hydrogenation and catalyst. The reaction temperature is controlled at 360-385°C, the reaction pressure is controlled at about 15-18MPa, the hydrogen-oil ratio is controlled at 800:1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com