Method for preparing natural gas/liquefied natural gas by denitrifying nitrogen-containing methane gas

A technology of liquefied natural gas and methane gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of waste of pressure and loss of methane, and achieve the effect of high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

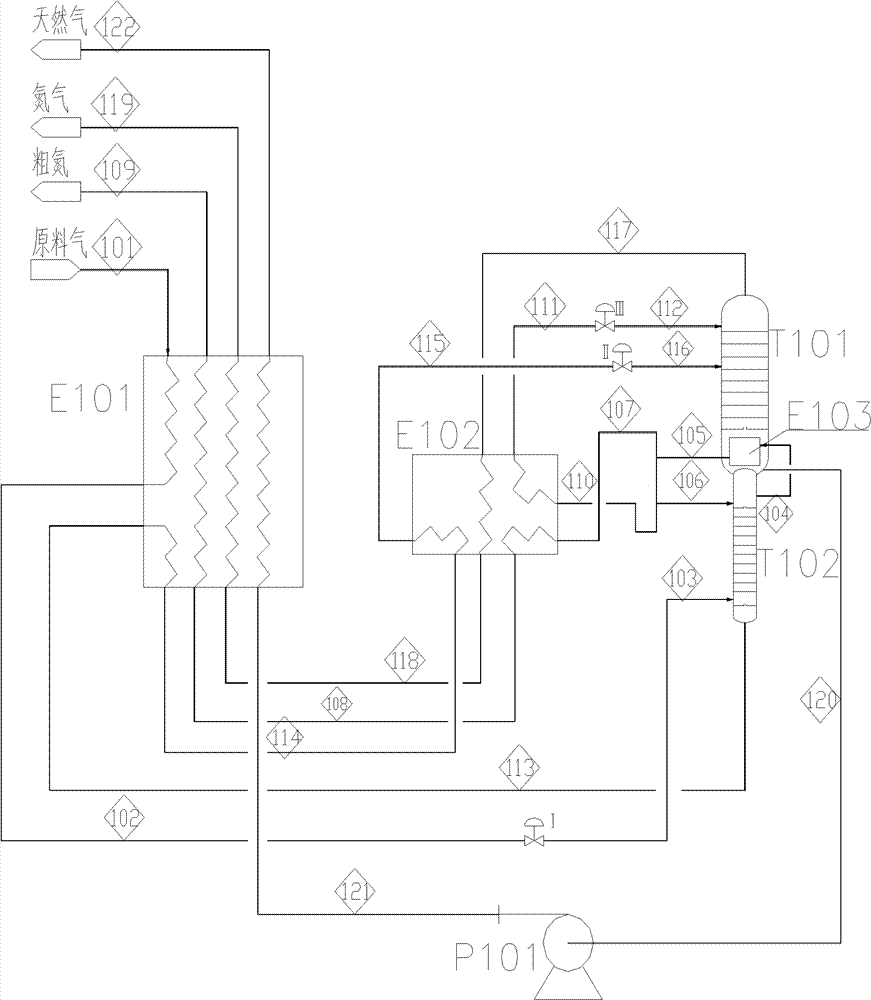

[0042] The flow chart of this embodiment is as follows figure 1 As shown, the nitrogen-containing methane gas enumerated in this embodiment is the gas produced by the purge gas of synthetic ammonia after membrane separation and recovery of hydrogen. The process steps of using this gas to produce liquefied natural gas (LNG) through double-tower rectification are as follows:

[0043] (1) Raw material gas precooling:

[0044] The raw material gas 101 enters the denitrification device, and is first condensed to a liquid state or partially condensed to a liquid state 102 in the condenser E101, and then the pressure is reduced to the operating pressure of the high-pressure tower (lower tower) T102 through the first pressure reducing valve I, from Stream 103 is introduced into high-pressure tower T102 for rectification;

[0045] (2) High-pressure column distillation:

[0046] In the high-pressure tower T102, the volatile components rich in nitrogen go upward along the tower height...

Embodiment 2

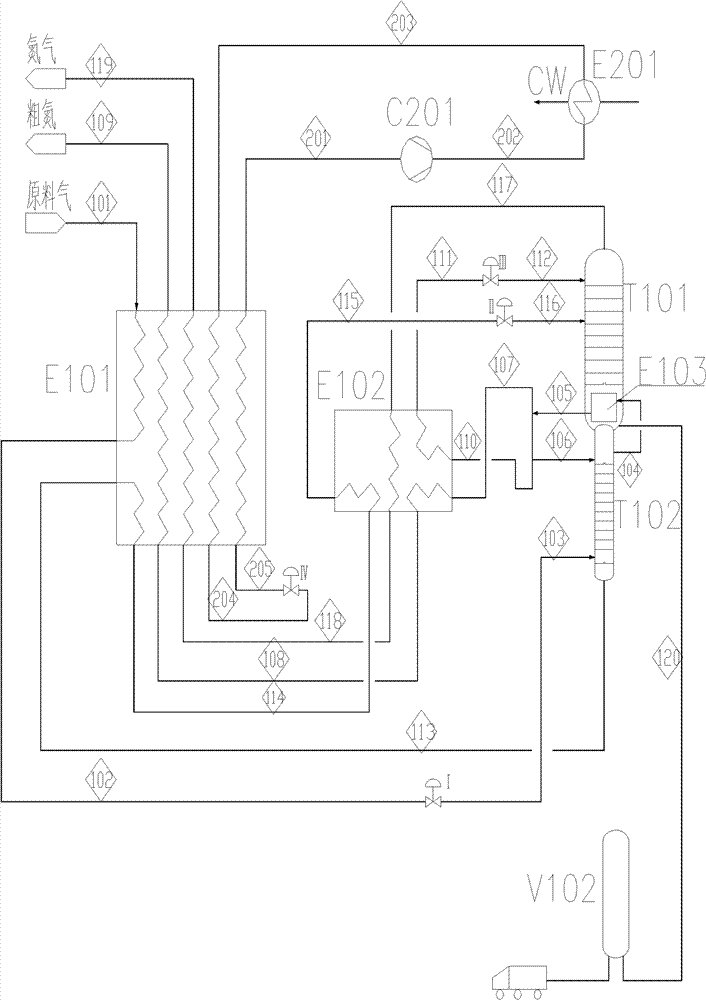

[0062] The flow chart of this embodiment is as follows figure 2 As shown, the nitrogen-containing methane gas enumerated in this embodiment is the gas produced by the purge gas of synthetic ammonia after membrane separation and recovery of hydrogen. The process steps of using this gas to produce liquefied natural gas (LNG) through double-tower rectification are as follows:

[0063] (1) Raw material gas precooling:

[0064] The feed gas 101 enters the denitrification device, and is first condensed to a liquid state or partially condensed to a liquid state 102 in the condenser E101, and then, if necessary, the pressure is reduced to the operating pressure of the high-pressure column T102 through the first pressure reducing valve I, and the 103 is introduced into the high-pressure tower T102 for rectification;

[0065] (2) High-pressure column distillation:

[0066] In the high-pressure tower T102, the volatile components rich in nitrogen go upward along the tower height, and ...

Embodiment 3

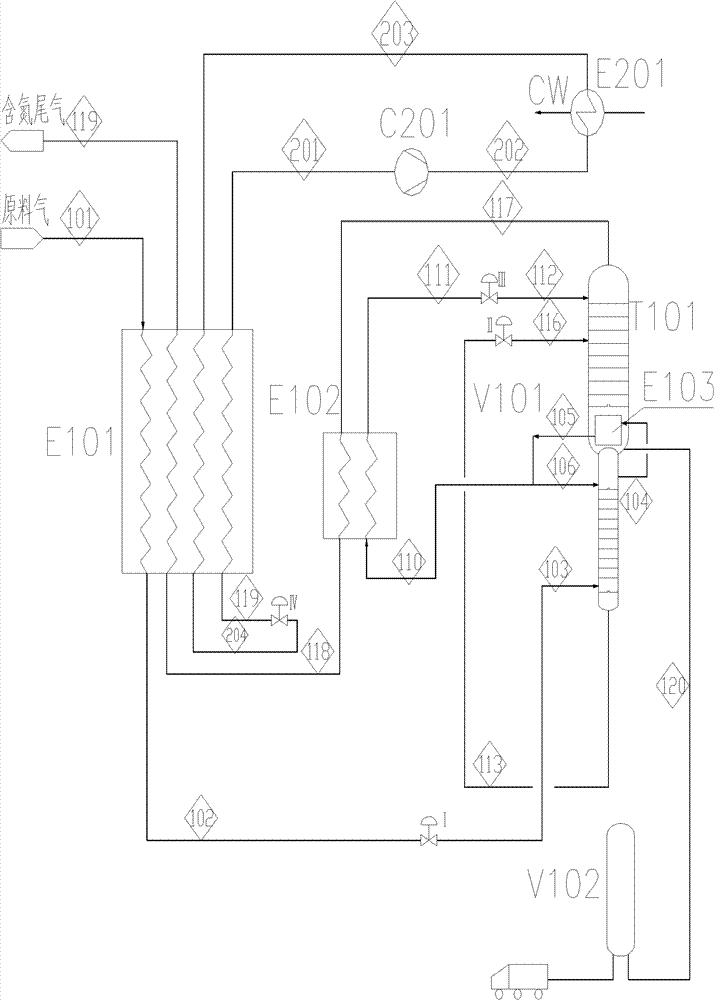

[0083] The flow chart of this embodiment is as follows image 3 As shown, the nitrogen-containing methane gas listed in this embodiment is the gas after catalytic deoxidation and decarbonation of coalbed methane. The process steps of using this gas to produce liquefied natural gas (LNG) through double-tower rectification are as follows:

[0084] (1) Raw material gas precooling:

[0085] The feed gas 101 enters the denitrification device, and is first condensed to a liquid state or partially condensed to a liquid state 102 in the condenser E101, and then, if necessary, the pressure is reduced to the operating pressure of the high-pressure column T102 through the first pressure reducing valve I, and the 103 is introduced into the high-pressure tower T102 for rectification;

[0086] (2) High-pressure column distillation:

[0087] In the high-pressure tower T102, the volatile components rich in nitrogen go upward along the tower height, and the stream 104 is drawn from the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com