Spheroidizing treater

The technology of spheroidizing treatment and spheroidizing agent is applied in the production process field of rare earth magnesium iron ferrosilicon spheroidizing agent flushing into the bag, which can solve the problems of low absorption rate of effective elements and violent reaction, and achieves the production environment. The effect of improving and eliminating environmental pollution and less liquid slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

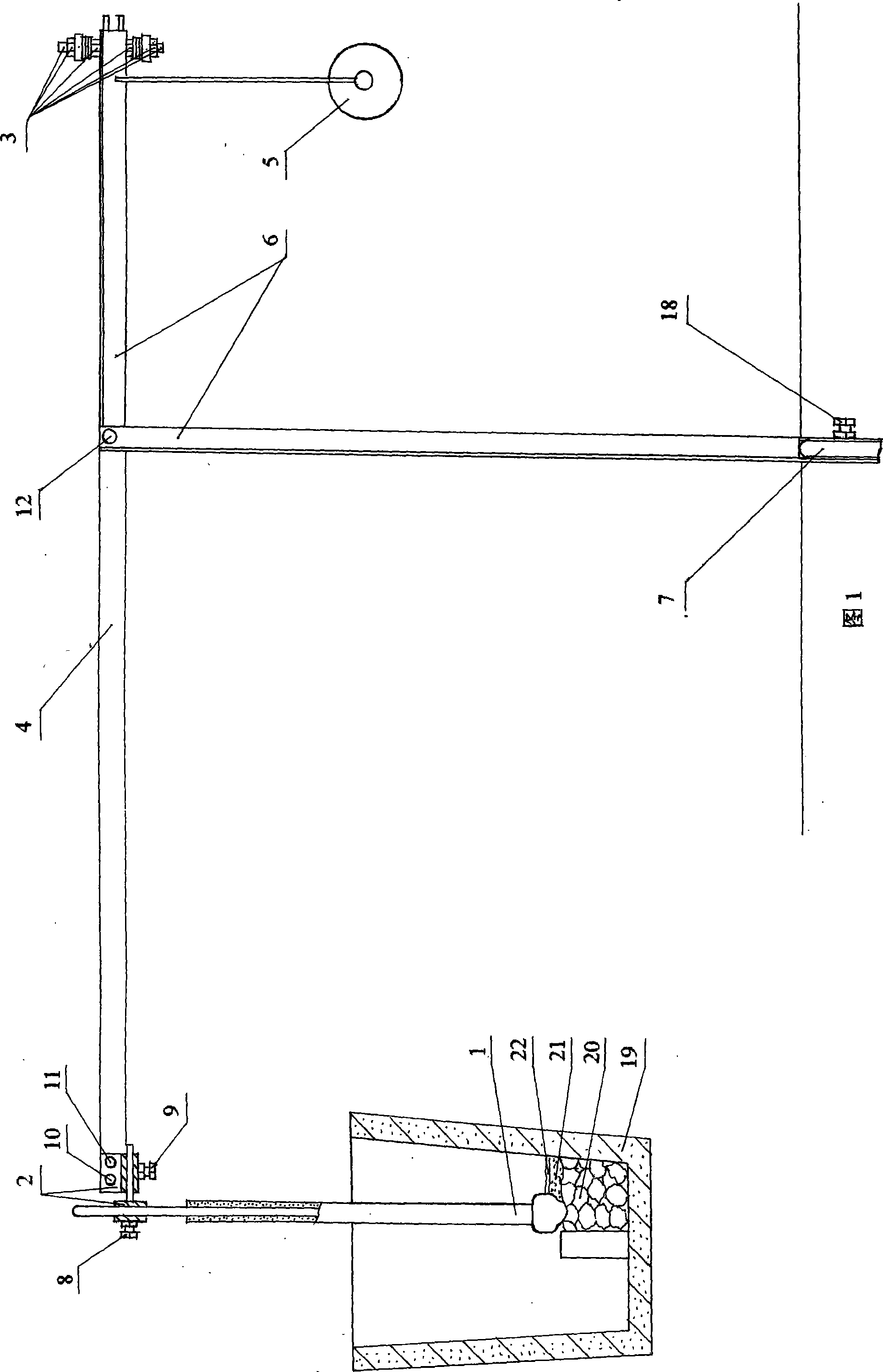

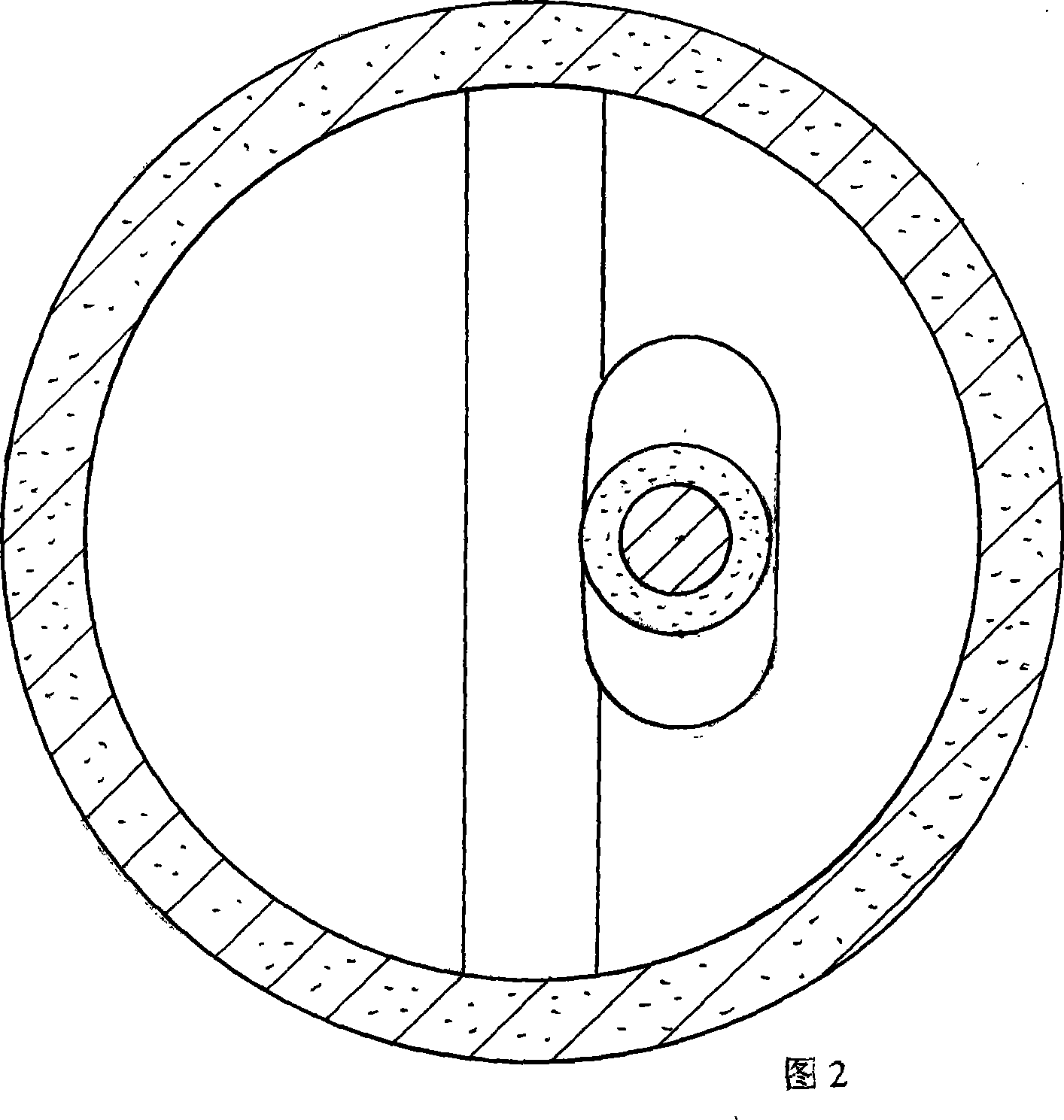

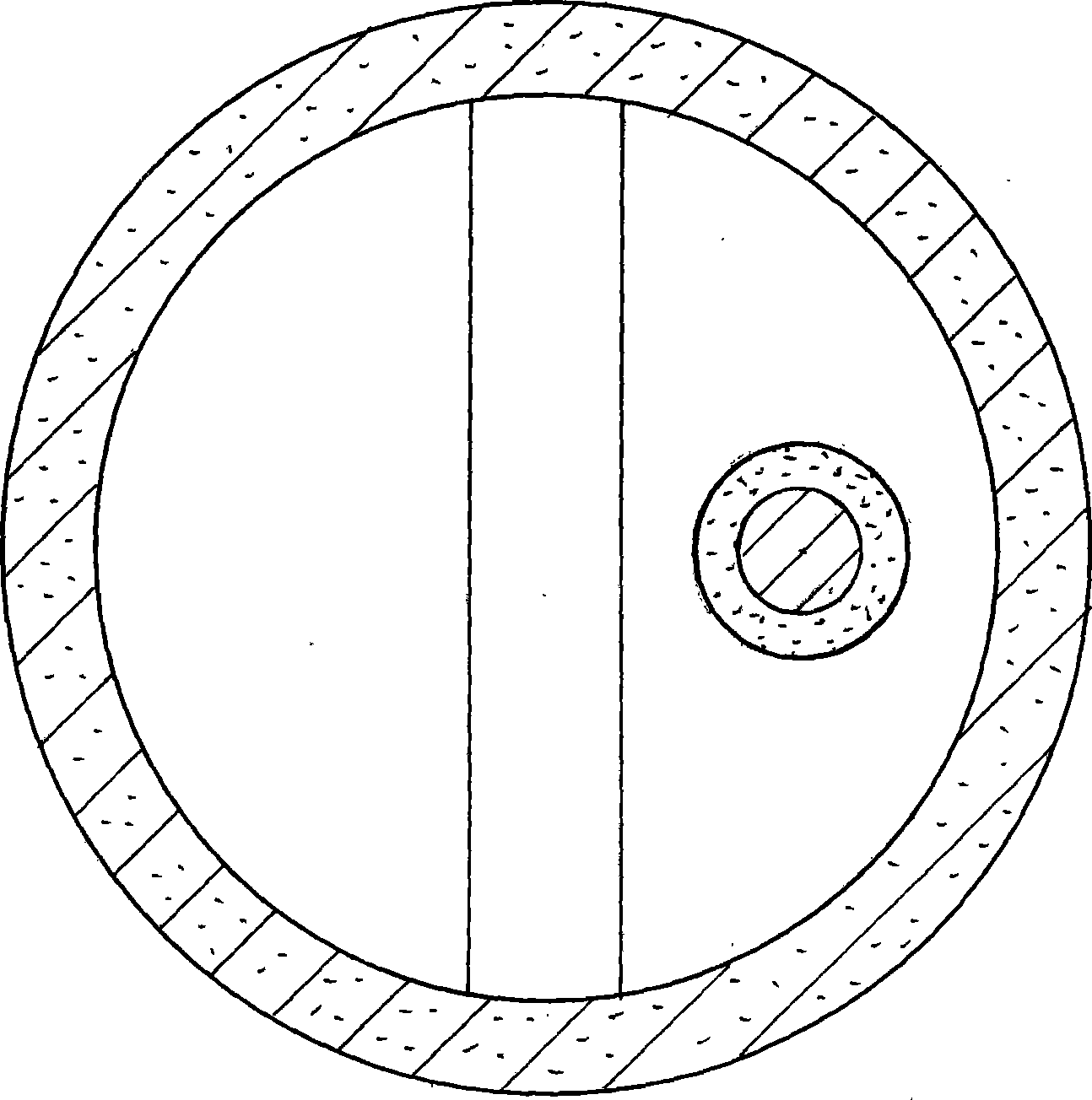

[0016] It is carried out under the smelting conditions of the cold air cupola, the melting rate is 2 tons / hour, and the attached figure 1 The spheroidizing treatment device shown adopts embankment-type molten iron ladle, and the weight of molten iron per ladle is 500kg. The red hot ladle is used for continuous operation. The support rod pressure head 1 is circular. The amount of sulfur is 0.036%, the addition of the melted nodulizer containing Mg15%, RE1.5% and Si53% is 1.1%, the addition of 0.3% to the 72SiFe inoculant bag, the addition of 0.2% to the secondary silicon barium inoculation, the reaction start time After 30 seconds of tapping the molten iron, when the spheroidizing reaction time is controlled to be more than 100 seconds, it is a boiling reaction of molten iron without magnesium light. The sample is taken 9 minutes after the spheroidizing reaction, the spheroidizing level is 2, the tensile strength is 487Mpa, and the elongation is 21. %.

Embodiment 2

[0018] Carried out under cold air cupola smelting conditions, the melting rate is 5 tons / hour, and the attached figure 1 The spheroidizing treatment device shown adopts embankment-type molten iron ladles. The weight of molten iron per ladle is 1100kg. The red hot ladle is used for 8 hours of continuous operation. According to the different wall thickness of castings, use Mg16%, RE3% and Si58% melted spheroidizers to break down to a particle size of <50mm. The amount of silicon barium inoculation added is 0.2%. After the molten iron is poured into the ladle for 60 seconds, the spheroidization reaction starts. When the reaction time is more than 2 minutes and 30 seconds, it is a magnesium-free molten iron boiling reaction. When the reaction time is 1 minute and 30 seconds Magnesium appeared, but the intensity of magnesium light was significantly lower than that produced by traditional spheroidization reaction, and there was no molten iron splashing phenomenon. The sample was tak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com