High magnesium-manganese-chromium-cobalt-aluminum alloy for manufacturing welding wires and preparation method thereof

A high-magnesium-manganese-chromium-cobalt-aluminum alloy and welding wire technology, which can be used in manufacturing tools, welding equipment, metal processing equipment, etc. Mechanical properties, effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The chemical composition of the high-magnesium-manganese-chromium-cobalt aluminum alloy welding wire of the present invention is calculated by mass percentage: Mg: 4.5%, Mn: 0.85%, Cr: 1.2%, Zr: 0.12%, Co: 0.1%, Ti: 0.0025 %, B: 0.008%, Si: 0.005%, the sum of other impurity elements is less than 0.5%, and the balance is Al.

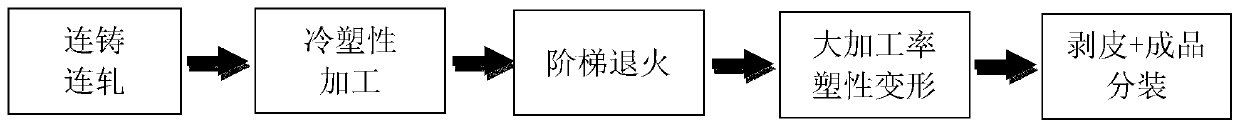

[0092] Using industrial pure aluminum, industrial pure magnesium and Al-Mn, Al-Cr, Al-Co and other intermediate alloys as raw materials, 6 tons of alloys are prepared according to the chemical composition requirements, and high magnesium manganese chromium cobalt aluminum alloy welding wire is prepared according to the following process Wire:

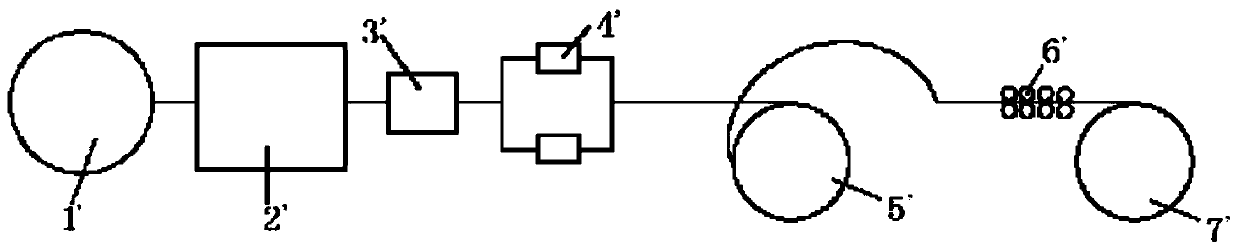

[0093] (1) The industrial pure aluminum, industrial pure magnesium and Al-Mn, Al-Cr, Al-Zr, Al-Co, Al-Ti master alloys are melted in the melting furnace 1'according to the formula ratio, and the melting temperature is 770 ℃, after the alloy is melted, it is transferred to the holding furnace 2'for composition ad...

Embodiment 2

[0100] The chemical composition of a high-magnesium-manganese-chromium-cobalt aluminum alloy welding wire according to the present invention is calculated by mass percentage: Mg: 5%, Mn: 0.7%, Cr: 0.8%, Zr: 0.08%, Co: 0.05%, Ti: 0.0015 %, V: 0.006%, Nb: 0.005%, the sum of other impurity elements is less than 0.5%, and the balance is Al.

[0101] Using industrial pure aluminum, industrial pure magnesium and Al-Mn, Al-Cr, Al-Co and other intermediate alloys as raw materials, 6 tons of alloys are prepared according to the chemical composition requirements, and high magnesium manganese chromium cobalt aluminum alloy welding wire is prepared according to the following process Wire:

[0102] (1) Industrial pure aluminum, industrial pure magnesium and Al-Mn, Al-Cr, Al-Zr, Al-Co, Al-Ti, Al-V master alloys are melted in a melting furnace according to a certain proportion, and melted After the alloy is melted at a temperature of 750°C, it is transferred to the holding furnace 2'for composit...

Embodiment 3

[0108] The chemical composition of a high-magnesium-manganese-chromium-cobalt aluminum alloy welding wire of the present invention is calculated by mass percentage: Mg: 5.5%, Mn: 0.5%, Cr: 0.4%, Zr: 0.04%, Co: 0.05%, V: 0.005 %, Ag: 0.0015%, Cu: 0.0008%, the sum of other impurity elements is less than 0.5%, and the balance is Al.

[0109] (1) Put industrial pure aluminum, industrial pure magnesium and Al-Mn, Al-Cr, Al-Zr, Al-Co, Al-V, Al-Ag and Al-Cu master alloys in a certain proportion in the melting furnace The melting is carried out at a melting temperature of 750°C. After the alloy is melted, chlorine is used for refining, and the slag is removed after refining.

[0110] Release the processed aluminum alloy melt and transfer it to the degassing box for degassing. Use 99.998% N for degassing 2 After degassing, the hydrogen content of the melt does not exceed 0.19ml / 100gAl; then the degassed melt is transferred to the filter box for filtration, and the filtration accuracy is 35p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com