Spheroidizing treater and process

The technology of spheroidizing treatment and spheroidizing agent is applied in the field of spheroidizing treatment device and spheroidizing treatment technology, which can solve the problems of low absorption rate of effective elements and violent reaction, and achieves improvement of production environment, elimination of environmental pollution, and less cooling of molten iron. Effect

Inactive Publication Date: 2007-09-05

河北贝广电力设备有限公司

View PDF1 Cites 23 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem of violent reaction and low absorption rate of effective elements when entering into the bag for spheroidization treatment, stabilize and improve product quality, reduce production cost and achieve energy recycling

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

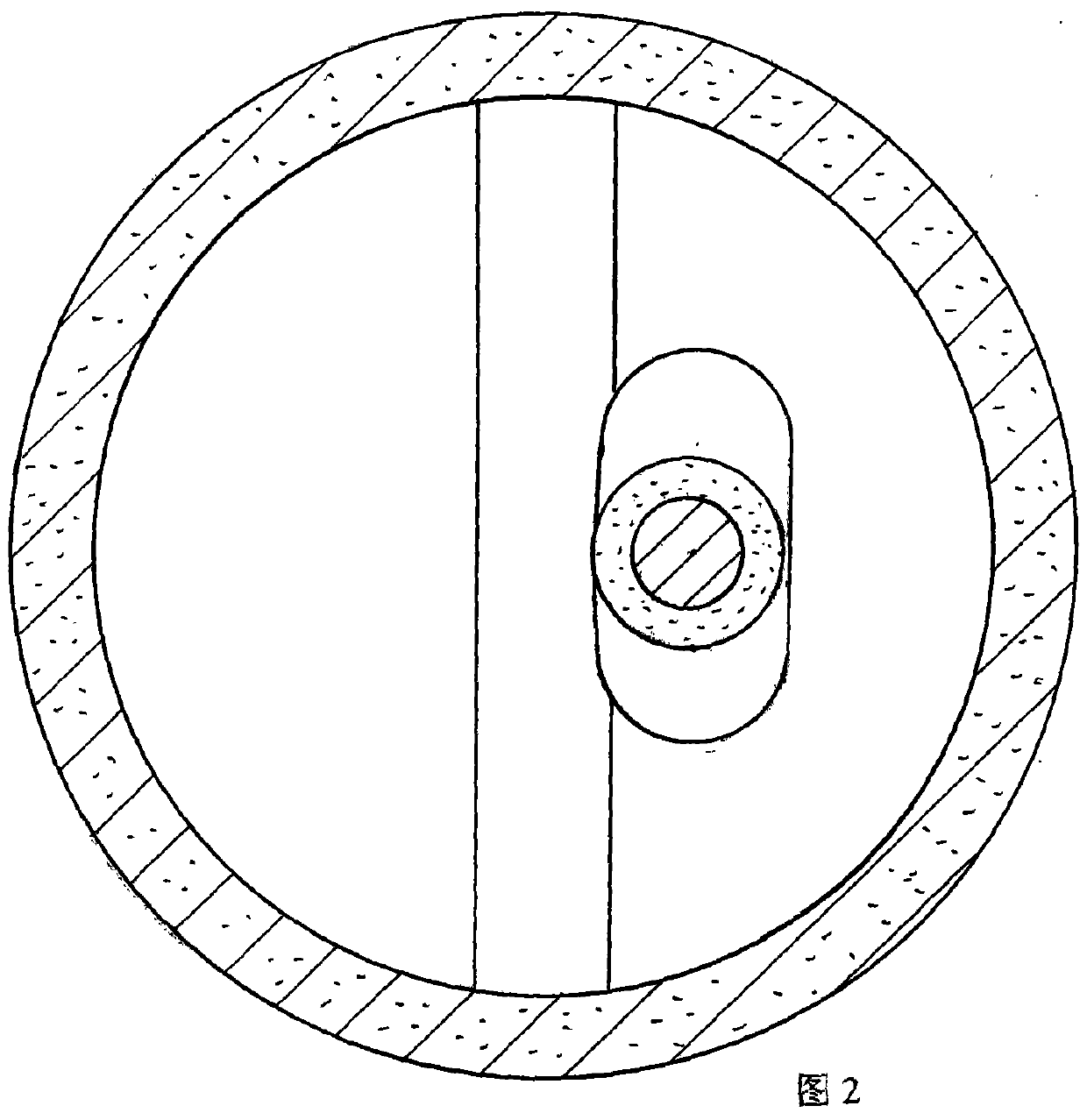

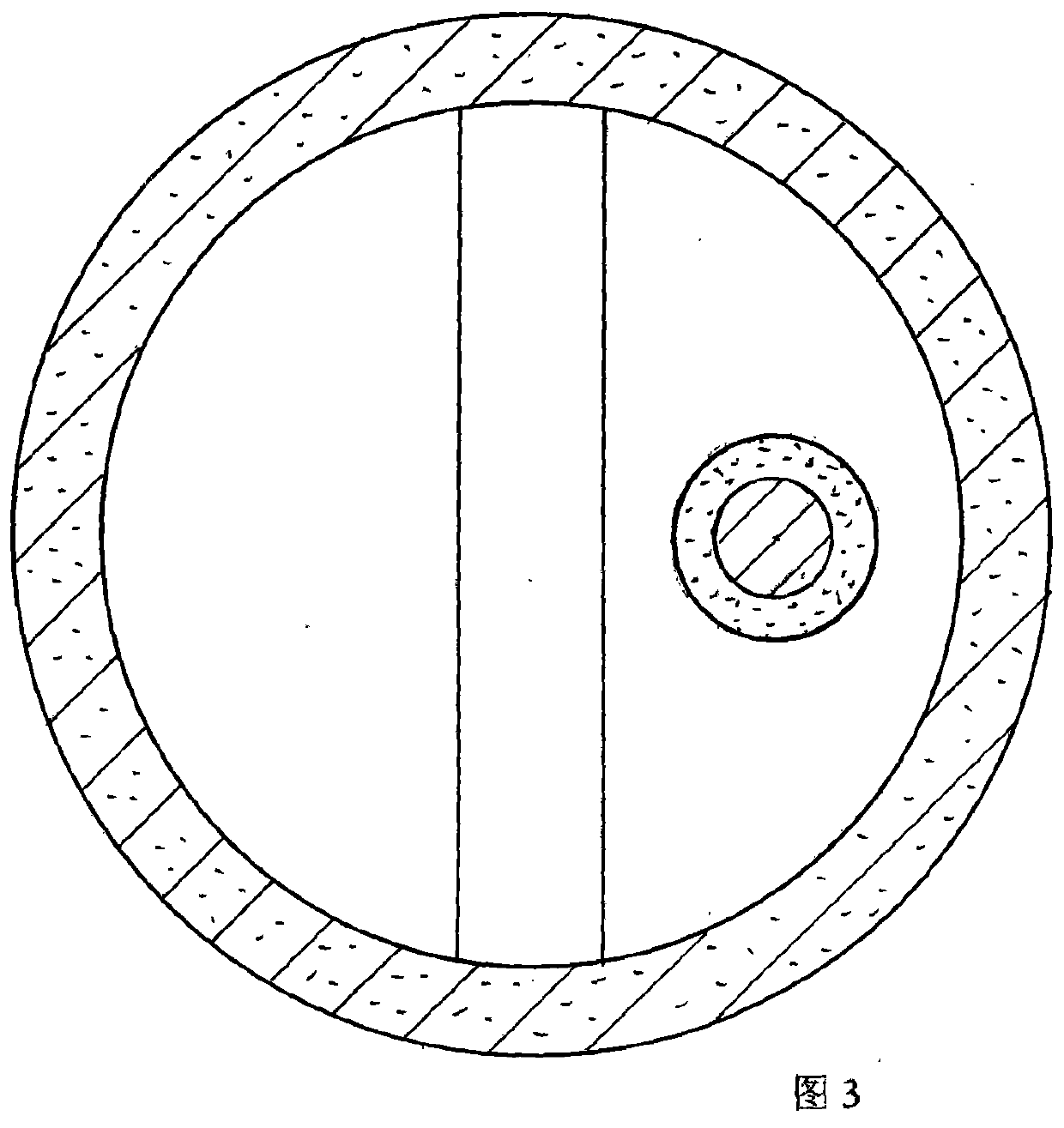

A spheroidizing treater for producing spheroidal graphite cast iron is carried out by adjusting bearing rod head and dam seam and controlling iron-water and nodulizer contact. It adopts waste-heat one-step method and controls spheroidizing reactive time and strength; the spheroidizing agent consists of Mg<=20%, RE<=3% and Si<=65%. It's simple, cheap and can be used for large-scale continuous production.

Description

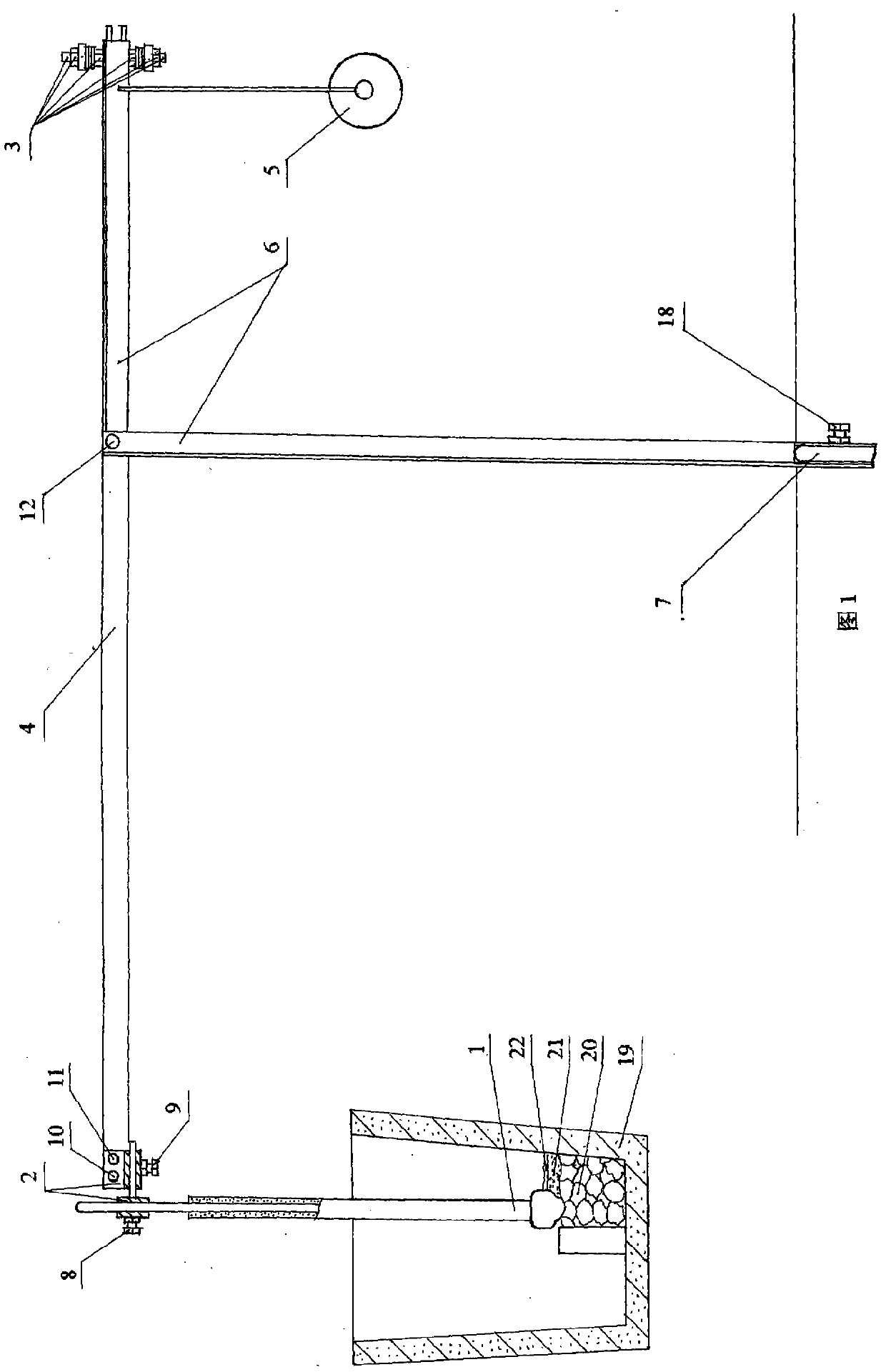

technical field The invention relates to a spheroidizing treatment device and a spheroidizing treatment process for producing nodular cast iron, more specifically a production process for spheroidizing treatment by using a rare earth magnesium ferrosilicon nodulizing agent to rush into a bag. Background technique In the production of ductile iron castings, the production process of spheroidizing by flushing into the ladle is generally adopted. During the spheroidizing process of flushing into the bag, rare earth magnesium-silicon-iron alloy is widely used as the spheroidizing agent. The spheroidizing treatment by flushing into the ladle is easy to operate, and the molten iron does not need to be poured after the spheroidizing treatment to reduce the temperature. For a long time, counterparts at home and abroad have made unremitting efforts to study the technology of spheroidizing treatment by flushing into the bag and the production process of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C33/10

Inventor 刘年路

Owner 河北贝广电力设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com