Converter gas purification treatment method

A technology for purification treatment of converter gas, applied in the field of converter gas purification, can solve the problems of insufficient purification of gas, waste of resources, low conversion rate, etc., and achieve the effect of improving purification effect, good purification effect and efficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

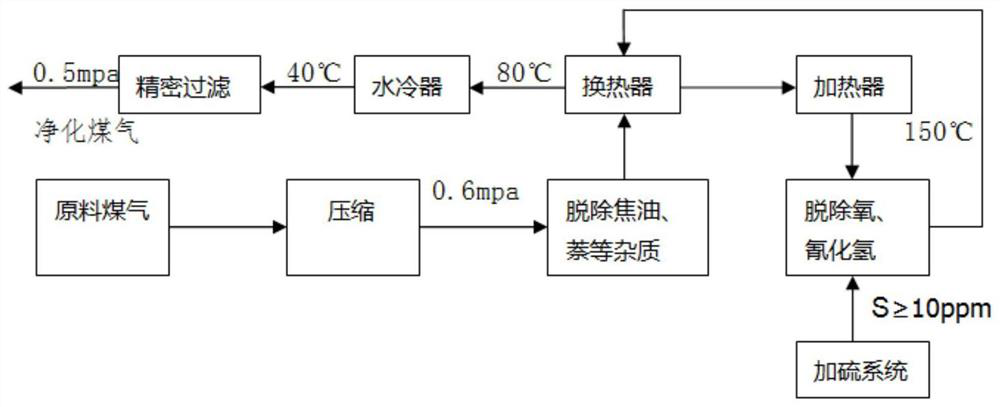

[0038] Such as figure 1 As shown, a converter gas purification treatment method of the present embodiment comprises the following steps:

[0039] S1. Use activated carbon to remove impurities in the gas;

[0040] S2. Using the sulfided molybdenum series multi-component catalyst to remove oxygen and cyanide in the gas.

Embodiment 2

[0042] This embodiment is a definition optimized on the basis of the above-mentioned embodiment 1, such as figure 1 As shown, a converter gas purification treatment method of the present embodiment comprises the following steps:

[0043] S1. Use activated carbon to remove impurities in the gas;

[0044] S2. Using the sulfided molybdenum series multi-component catalyst to remove oxygen and cyanide in the gas.

[0045] Further, the molybdenum-based multi-component catalyst in the sulfided state is NSTO-1 sulfur resistant deoxidizer.

[0046] In the process of producing ethanol by biological fermentation of converter gas, the gas needs to be purified to remove most of the oxygen and cyanide harmful to fermenting organisms in the gas. Processing method of the present invention is divided into following two parts:

[0047] First, considering that the gas may contain tar, naphthalene, dust and other impurities that are harmful to the catalyst, a protective tank is installed at th...

Embodiment 3

[0054]This embodiment is a definition optimized on the basis of the above-mentioned embodiment 2, such as figure 1 As shown, a converter gas purification treatment method of the present embodiment comprises the following steps:

[0055] S1. Use activated carbon to remove impurities in the gas;

[0056] S2. Using the sulfided molybdenum series multi-component catalyst to remove oxygen and cyanide in the gas.

[0057] Further, the molybdenum-based multi-component catalyst in the sulfided state is NSTO-1 sulfur resistant deoxidizer.

[0058] In the process of producing ethanol by biological fermentation of converter gas, the gas needs to be purified to remove most of the oxygen and cyanide harmful to fermenting organisms in the gas. Processing method of the present invention is divided into following two parts:

[0059] First, considering that the gas may contain tar, naphthalene, dust and other impurities that are harmful to the catalyst, a protective tank is installed at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com