Refrigeration and separation tank for producing liquefied natural gas

A technology of liquefied natural gas and separation tank, which is applied in separation method, dispersed particle separation, gas fuel and other directions, can solve the problems of affecting the service life of subsequent devices, liquid retention, equipment loss, etc., and achieves good gas-liquid separation effect, convenience and stability Work, improve the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

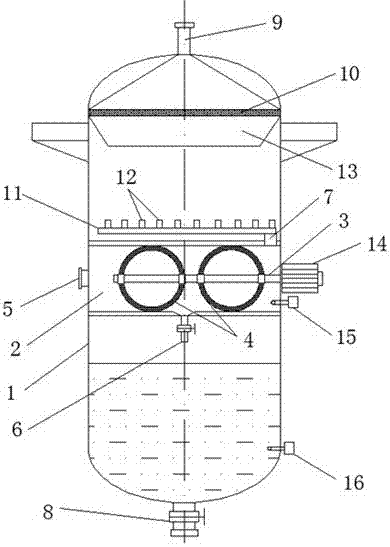

[0015] Embodiment 1: as figure 1 A refrigeration separation tank for the production of liquefied natural gas is shown, the refrigeration separation tank is a cylindrical shell 1, the middle part of the shell 1 is provided with a sealed cylindrical separation tank 2, the separation tank 2 A horizontally installed rotating shaft 3 is provided inside the rotating shaft 3, and a plurality of spherical filtrate screens 4 are arranged on the rotating shaft 3. The diameter of the filtrate screen 4 is the same as the inner diameter of the separation tank 2, and the housing 1 on the side of the separation tank 2 A feed port 5 is provided, a rotating motor 14 is provided on the housing 1 on the other side of the separation tank 2, and the rotating motor 14 is connected to the rotating shaft 3, and an air outlet 7 is provided on the top of the separation tank 2 on one side of the rotating motor 14 , the bottom of the separation tank 2 is provided with a drain port 6, the top of the housi...

Embodiment 2

[0016] Embodiment 2: as figure 1 As shown, the top of the housing 1 is provided with a secondary filtrate screen 10, and the secondary filtrate screen 10 is arranged directly below the tank exhaust port 9, and a conical Deflector 13; under normal circumstances, the gas and liquid have been completely separated in the separation tank 2, but, in order to ensure the separation effect, the filtrate is further carried out through the secondary filtrate screen 10 to prevent the liquid medium from entering the follow-up device with the gas middle.

Embodiment 3

[0017] Embodiment 3: as figure 1 As shown, the top of the separation tank 2 is provided with an air flow distribution pipe 11, and a plurality of vertically upward distribution ports 12 are evenly distributed above the air flow distribution pipe 11, and the air flow distribution pipe 11 is connected to the air outlet 7; The pipe 11 evenly distributes the airflow, which facilitates the airflow to evenly pass through the tank exhaust port 9 and the secondary filtrate screen 10, and the device operates stably and is convenient for separation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com