Visual measurement system for size of film on conveying belt and measurement method thereof

A technology of visual measurement and conveyor belt, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of poor imaging quality of detection film, complicated calibration method, slow measurement speed, etc., and achieve good economic benefits, accurate measurement, and market Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

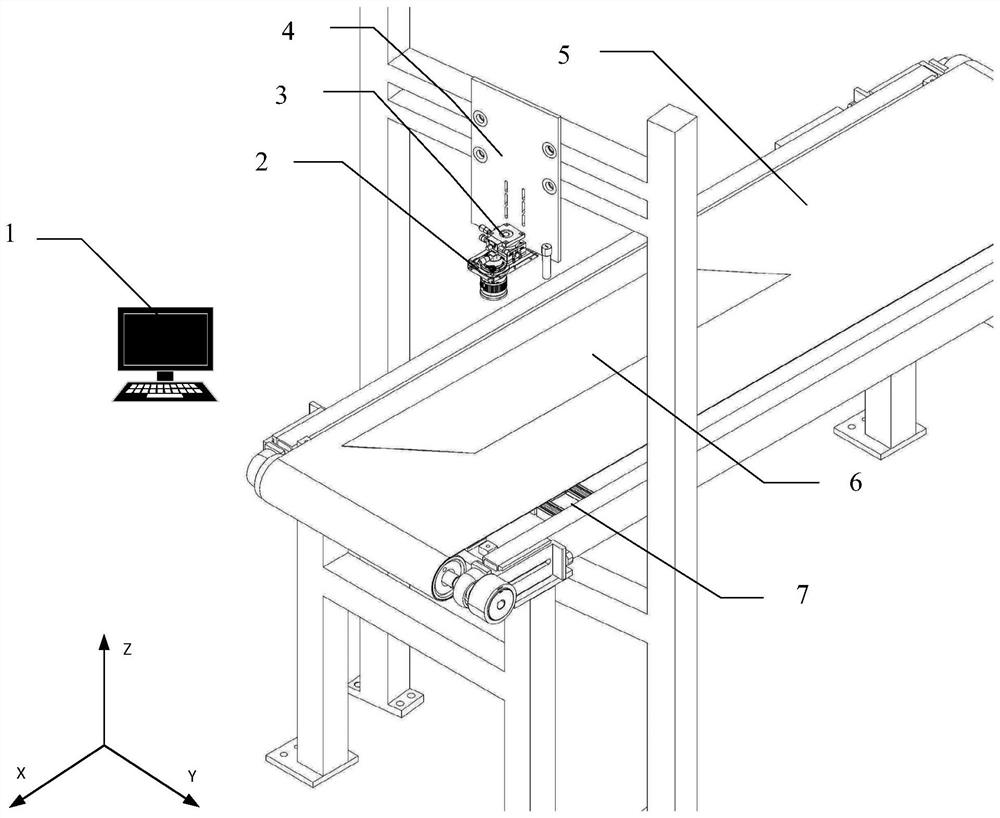

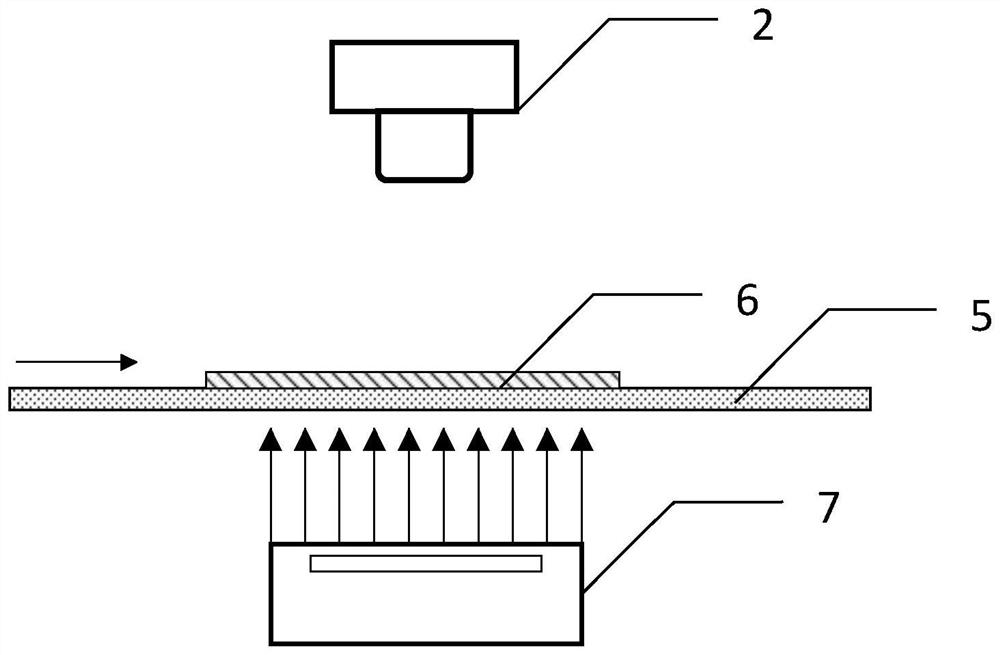

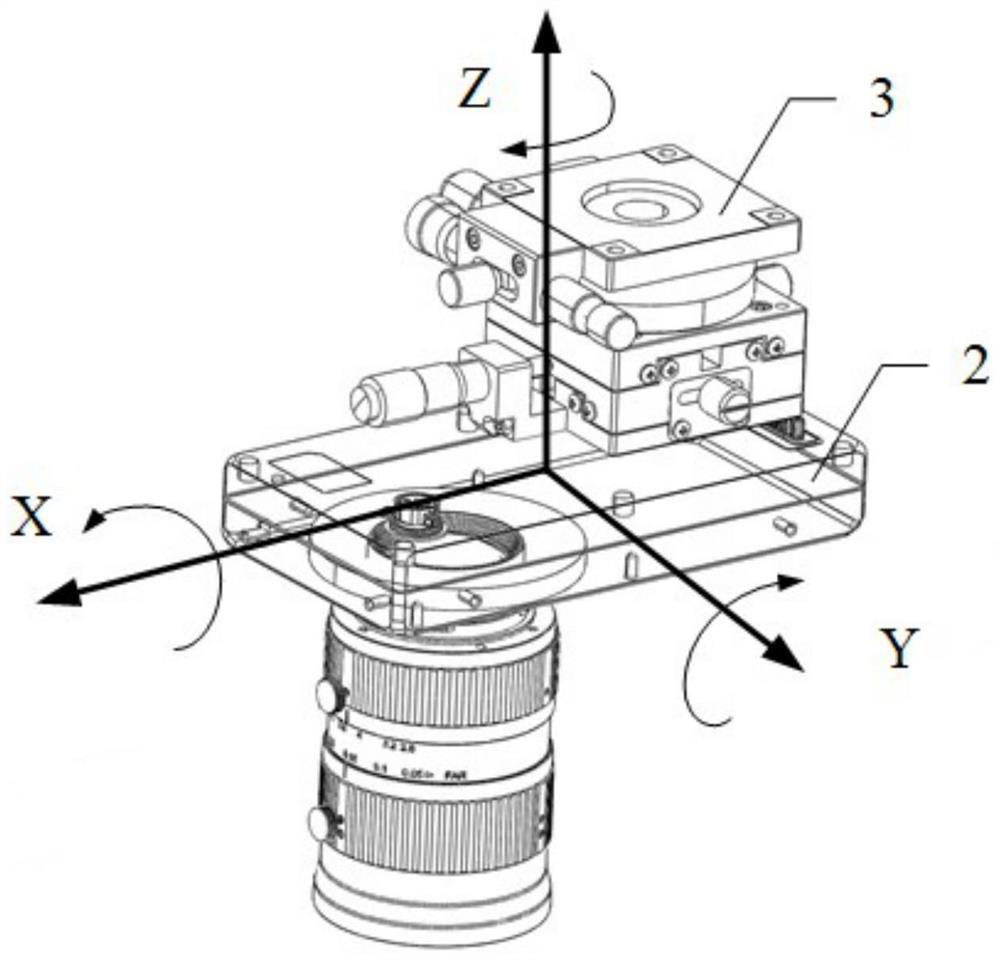

[0053] see Figure 1 to Figure 3 , in a preferred embodiment of the present invention, a visual measurement system for film size on a conveyor belt, including a main frame, a conveyor belt assembly 5, an infrared LED backlight source 7, a camera 2, a precision slide table 3, and a control device 1 The conveyor belt assembly 5 is installed on the main frame, an infrared LED backlight source 7 is arranged directly below the conveying surface, a camera 2 is arranged directly above the conveying surface of the conveyer belt assembly 5, and the camera 2 is connected to the control device 1. The collection part of the camera 2 is set facing the conveying surface and the infrared LED backlight 7. The camera 2 is installed on the precision sliding table 3, and the precision sliding table 3 is installed on the main frame, preferably through the camera bracket 4 Installed on the main frame.

[0054] In the present invention, the rotation of the precision sliding table 3 in the three di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com