An injection molded sheet picking manipulator

A technology of manipulators and injection molded sheets, which is applied in the direction of manipulators, program control manipulators, manufacturing tools, etc. It can solve the problems of deformation, damage and easy falling off of injection molded sheets, reduce noise and vibration, prevent waste of resources, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

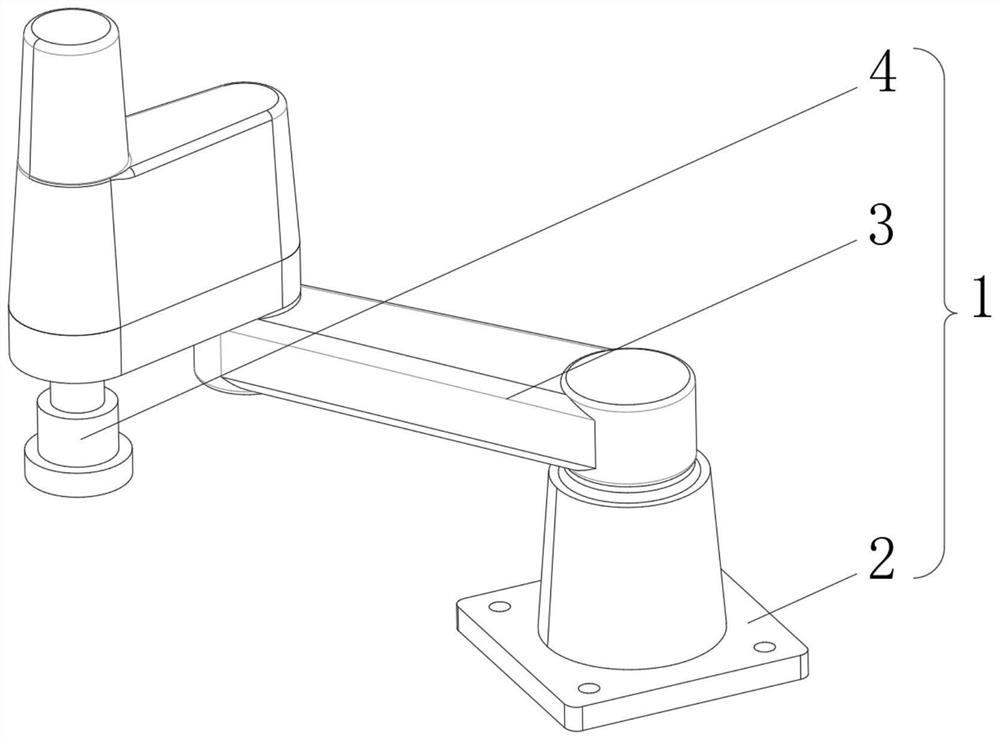

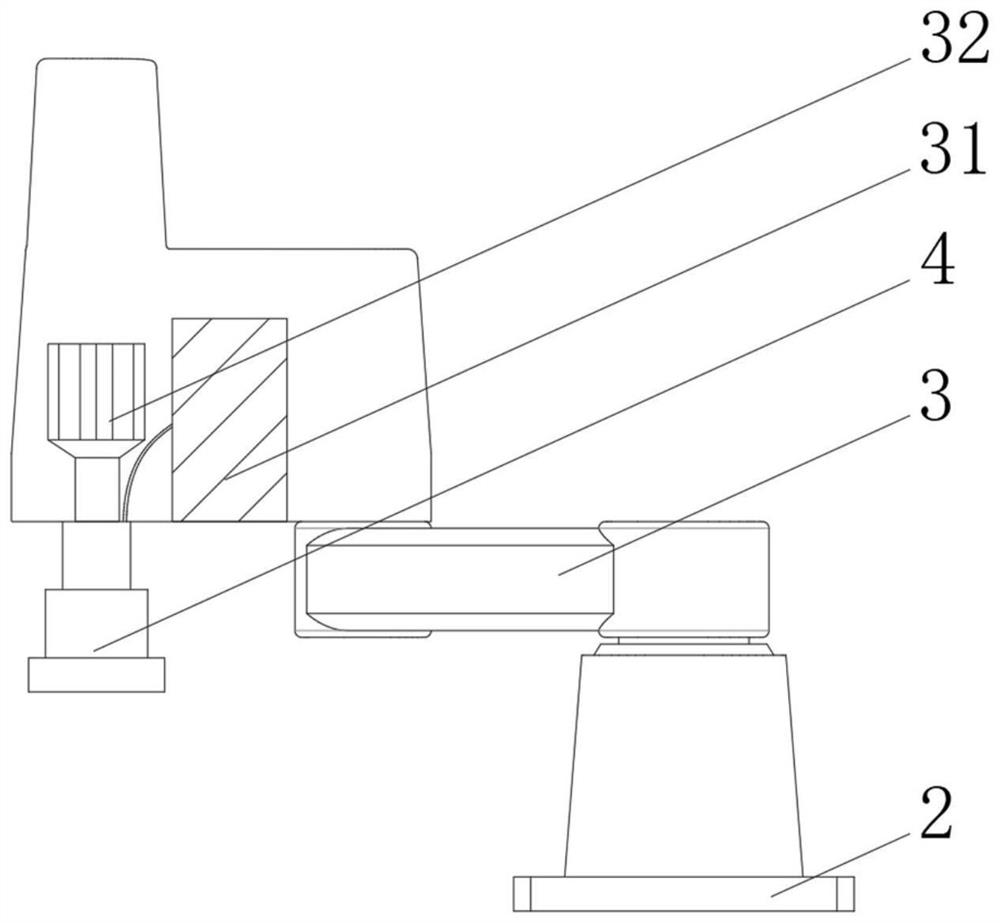

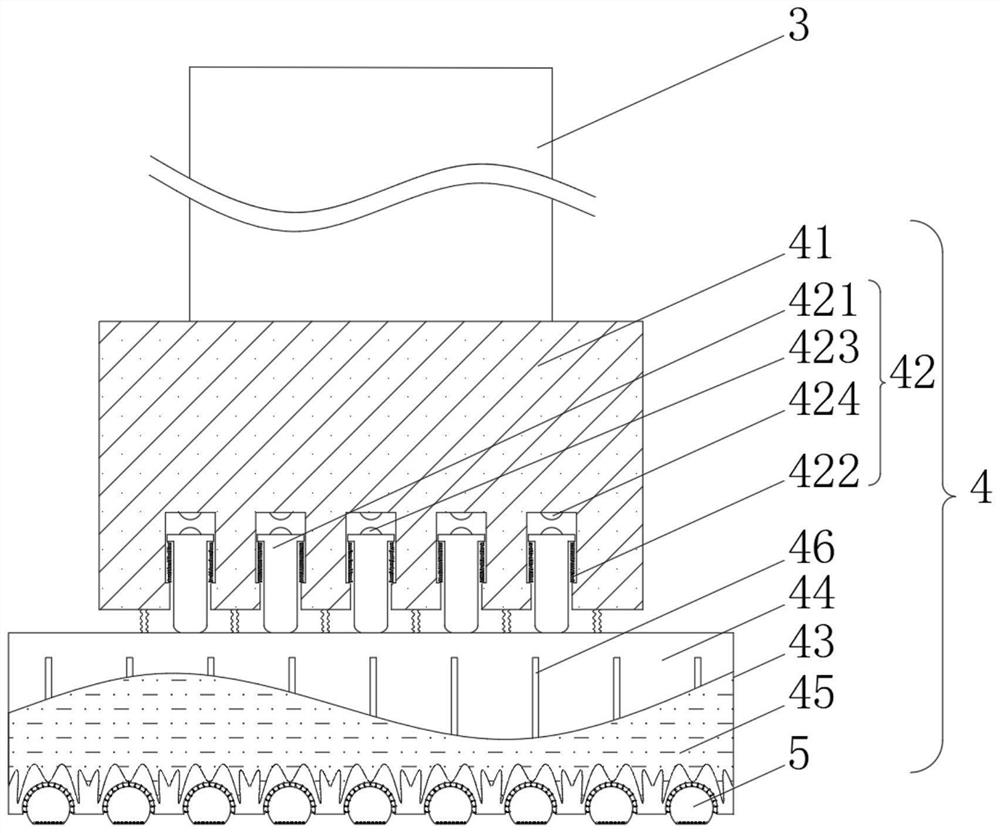

[0037] see also Figure 1-3The invention provides a technical scheme: an injection sheet pickup manipulator, which comprises an injection sheet pickup manipulator body 1 composed of a base 2, a manipulator arm 3 and a gripping mechanism 4. The top of the base 2 is fixedly connected with the bottom of the manipulator arm 3, the left bottom of the manipulator arm 3 is rotationally connected with the top of the gripping mechanism 4, the interior of the manipulator arm 3 is respectively provided with an suction vacuum pump 31 and a micro motor 32, and the gripping mechanism 4 includes an upper bearing block 41, The top of the upper bearing block 41 is rotationally connected with the micro motor 32 through a rotating rod. The inner part of the upper bearing block 41 is slidably connected with a touch mechanism 42, the bottom of the touch mechanism 42 is fixedly connected with a lower bearing block 43, the inner part of the lower bearing block 43 is respectively provided with an air cham...

Embodiment 2

[0044] see also Figure 4-1 , on the basis of embodiment 1, the invention provides a technical scheme: the suction plate mechanism 5 comprises a suction plate 51, the outside of the suction plate 51 is fixedly connected with the inside of the lower bearing block 43 through a telescopic rod, the inner wall of the suction plate 51 is fixedly connected with the bullet return shell 52, the interior of the bullet return shell 52 is provided with a rebound capsule 53, the bottom of the suction plate 51 is fixedly connected with the grab plate 54, and the top of the grab plate 54 is fixedly connected with the bottom of the bullet return shell 52, An air outlet mechanism 55 is arranged inside the low-pressure chamber surrounded by the cartridge case 52.

[0045] The air outlet mechanism 55 includes an air outlet pipe 551. The top of the air outlet pipe 551 successively passes through the cartridge case 52, the suction plate 51 and the cooling chamber 45. The top of the air outlet pipe 551 ...

Embodiment 3

[0049] see also Figure 1-5 On the basis of embodiment 1 and embodiment 2, the invention provides a technical scheme: the suction disc 56 comprises a software 561, the interior of the software 561 is provided with an absorption hole 562, the top of the absorption hole 562 is connected with the bottom of the contraction tube, and the bottom of the software 561 is provided with a soft body cavity 563.

[0050] When in use, when the suction mechanism 5 contacts the injection molded sheet, the software 561 in the suction disc 56 squeezes with the injection molded sheet, and the software 561 is elastically deformed. The absorption hole 562 absorbs the gas in the space surrounded by the software 561 and the injection molded sheet. Compared with the traditional, the software 561 in the suction disc 56 is designed as an elastomer to prevent damage to the injection molded sheet when the suction disc 56 squeezes with the injection molded sheet. At the same time, multiple groups of absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com