Formation method of local air gaps

An air-gap and air-gap technology, applied in the direction of electrical components, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of photolithography, etching production inconvenience, complex process, etc., to facilitate subsequent production and simplify the formation The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so that the realization process of how to use technical means to solve technical problems and achieve technical effects in the present invention can be fully understood and implemented accordingly.

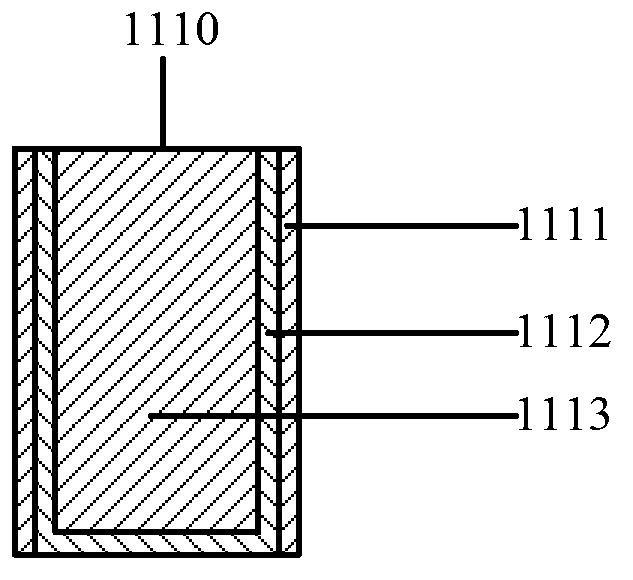

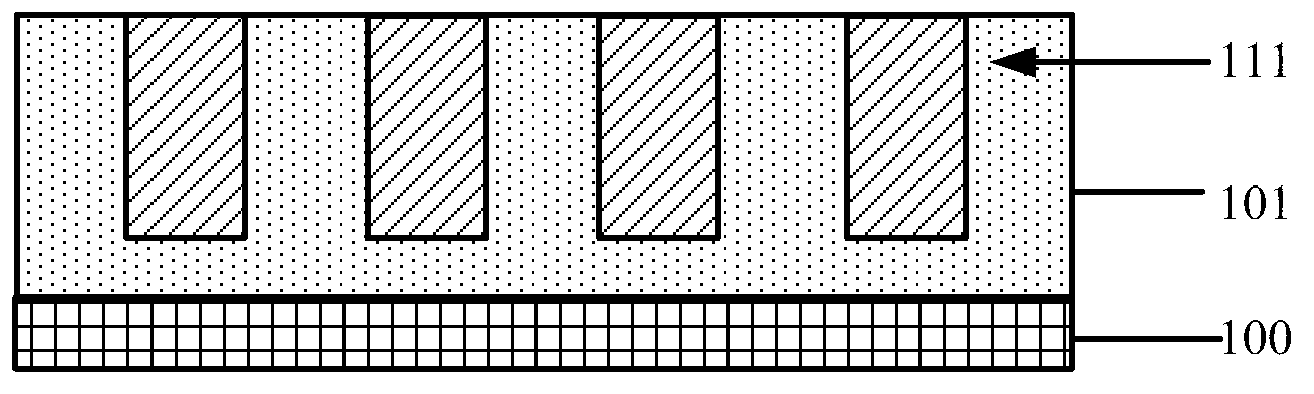

[0039] In the following embodiments of the present invention, the ultra-low dielectric film is combined with the film layer structure formed by the spin-on dielectric film, and on this basis, the first metal layer and the second metal layer and the through hole between the two layers of metal are formed. The interconnection structure is then etched and the ultra-low dielectric material is deposited to form an air gap.

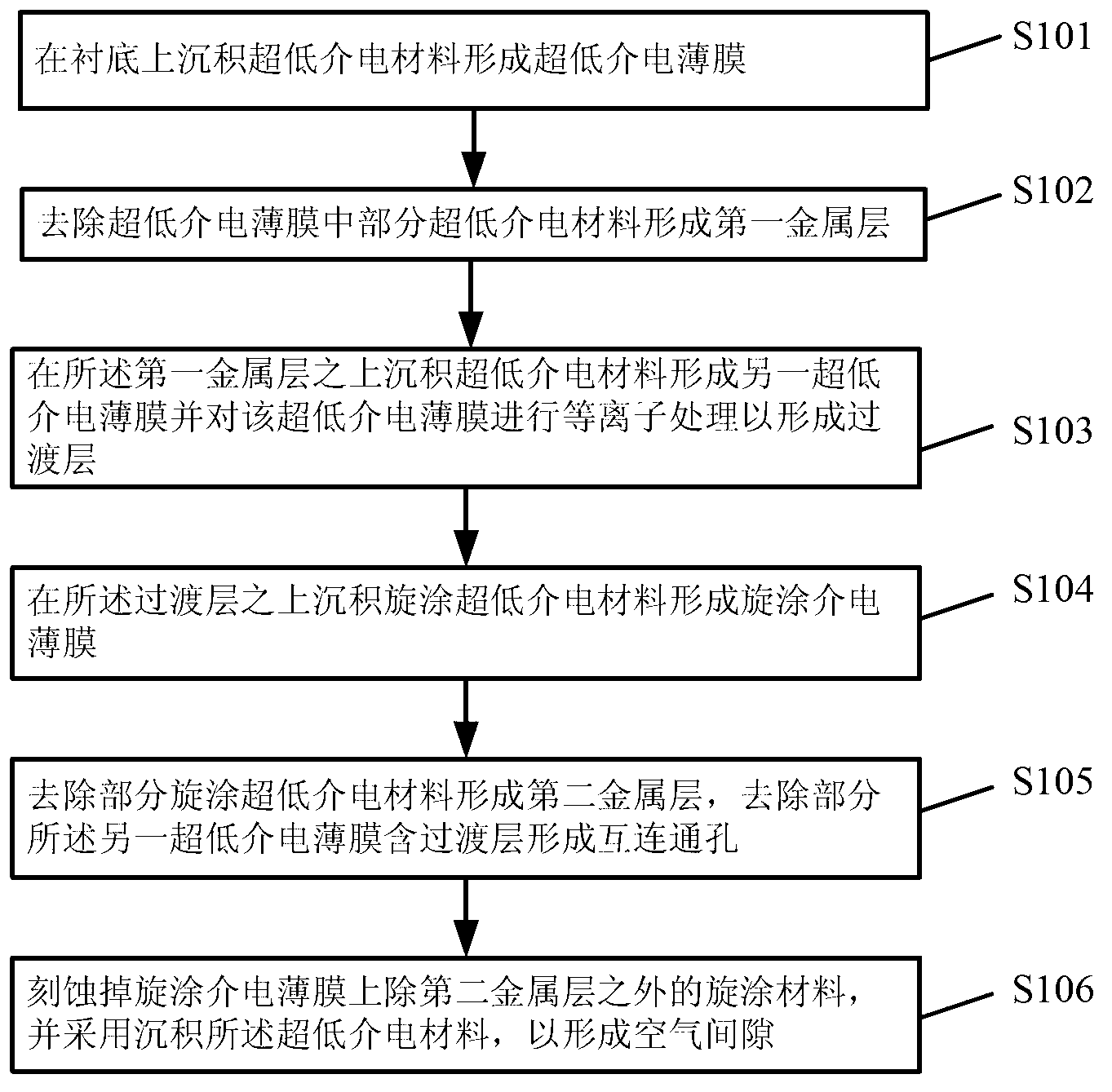

[0040] figure 1 It is a flow chart of the method for forming a local air gap in Embodiment 1 of the present invention, as figure 1 As shown, in this embodiment, the method for forming the local air gap may include:

[0041] Step S101...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com