Production mechanism for producing plastic raw material

A technology of raw materials and plastics, applied in the field of production institutions for the production of plastic raw materials, can solve problems such as low production efficiency, accumulation, complex production procedures, etc., and achieve the effect of convenient production and centralized waste collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

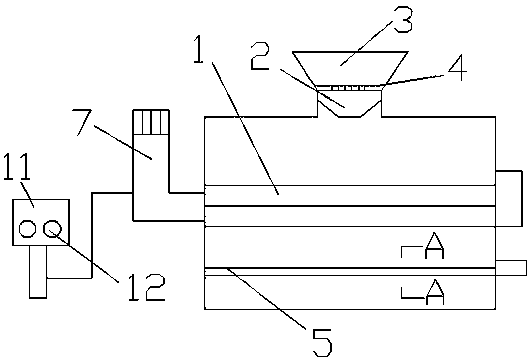

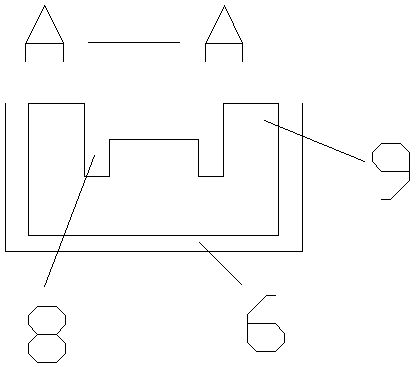

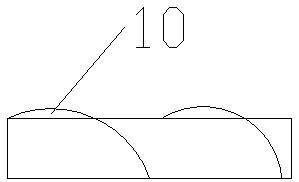

[0014] A production mechanism for producing plastic raw materials, comprising an extruding device 1, a fuselage is arranged outside the extruding device 1, and the extruding device 1 is an extruding rod symmetrically arranged in the fuselage, and the upper end of the extruding rod is provided with The blanking port 2 is provided with a blanking chamber 3 on the blanking port 2, and a flat screen 4 is arranged in the blanking chamber 3, and the flat screen 4 is welded and fixed in the blanking chamber 3, and the extrusion device 1. There is a drawing plate 5 at the bottom. The drawing plate 5 is fixed in the drawing groove 6. The drawing plate 5 moves back and forth in the drawing groove 6. There is a motor 7 on the body, and the motor 7 drives the extrusion device. 1 for rotation.

[0015] The drawer plate 5 is a stainless steel drawer plate, and protective grooves 8 are arranged on both sides of the drawer plate 5 .

[0016] A side vertical plate 9 is arranged beside the pro...

Embodiment 2

[0019] A production mechanism for producing plastic raw materials, comprising an extruding device 1, a fuselage is arranged outside the extruding device 1, and the extruding device 1 is an extruding rod symmetrically arranged in the fuselage, and the upper end of the extruding rod is provided with The blanking port 2 is provided with a blanking chamber 3 on the blanking port 2, and a flat screen 4 is arranged in the blanking chamber 3, and the flat screen 4 is welded and fixed in the blanking chamber 3, and the extrusion device 1. There is a drawing plate 5 at the bottom. The drawing plate 5 is fixed in the drawing groove 6. The drawing plate 5 moves back and forth in the drawing groove 6. There is a motor 7 on the body, and the motor 7 drives the extrusion device. 1 for rotation.

[0020] The drawer plate 5 is a stainless steel drawer plate, and protective grooves 8 are arranged on both sides of the drawer plate 5 .

[0021] A side vertical plate 9 is arranged beside the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com