Laminating film for display and display backlight module

A display and lamination film technology, applied in the field of optical films, can solve the problems of unsatisfactory stiffness, high production requirements, complex design, etc., and achieve the effect of convenient, easy and accurate subsequent production, improved product qualification rate, and simple design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

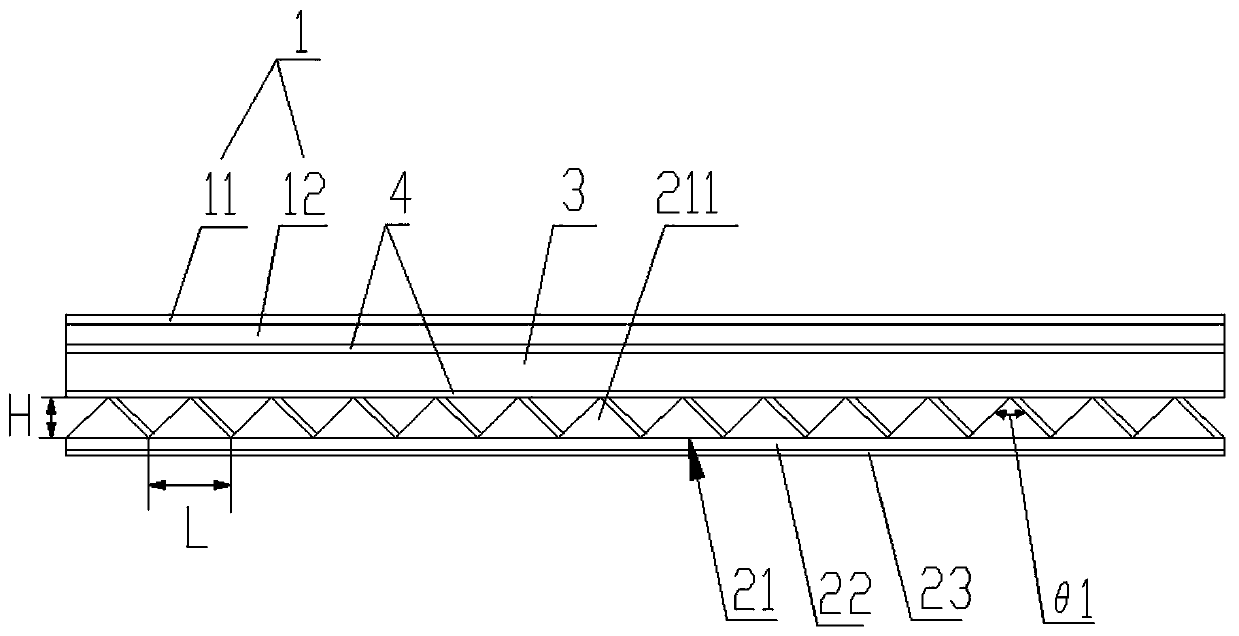

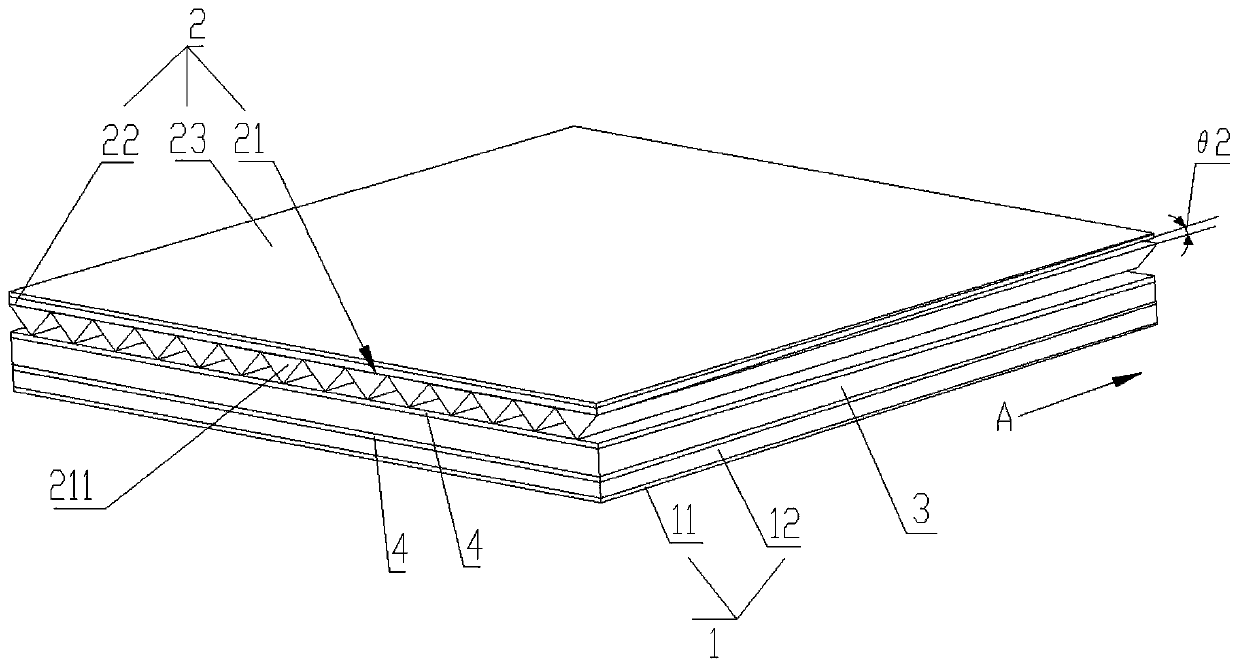

[0037] Such as figure 1 , figure 2As shown, the laminating film for display includes the atomized layer film 1, the base film 3 and the prism layer film 2 arranged in sequence from top to bottom, and the atomized layer film 1, the base film 3 and the prism layer film 2 are bonded sequentially The glue 4 fits each other.

[0038] The atomized layer film 1 includes a polarizing film 11, and the upper surface of the polarizing film 11 has an atomized coating layer 12 with a haze of 80%. Laminating glue 4 is coated on the lower surface of the atomized layer film 1 for surface-to-surface bonding with the base film 3 .

[0039] The base film 3 is a 50 μm optical grade chemically treated PET film. The base film 3 is first pre-coated, and the upper and lower surfaces of the base film 3 are coated with a coating liquid composed of water-based polyurethane and a curing agent with a mass ratio of 15:1, and then the laminating glue 4 is coated.

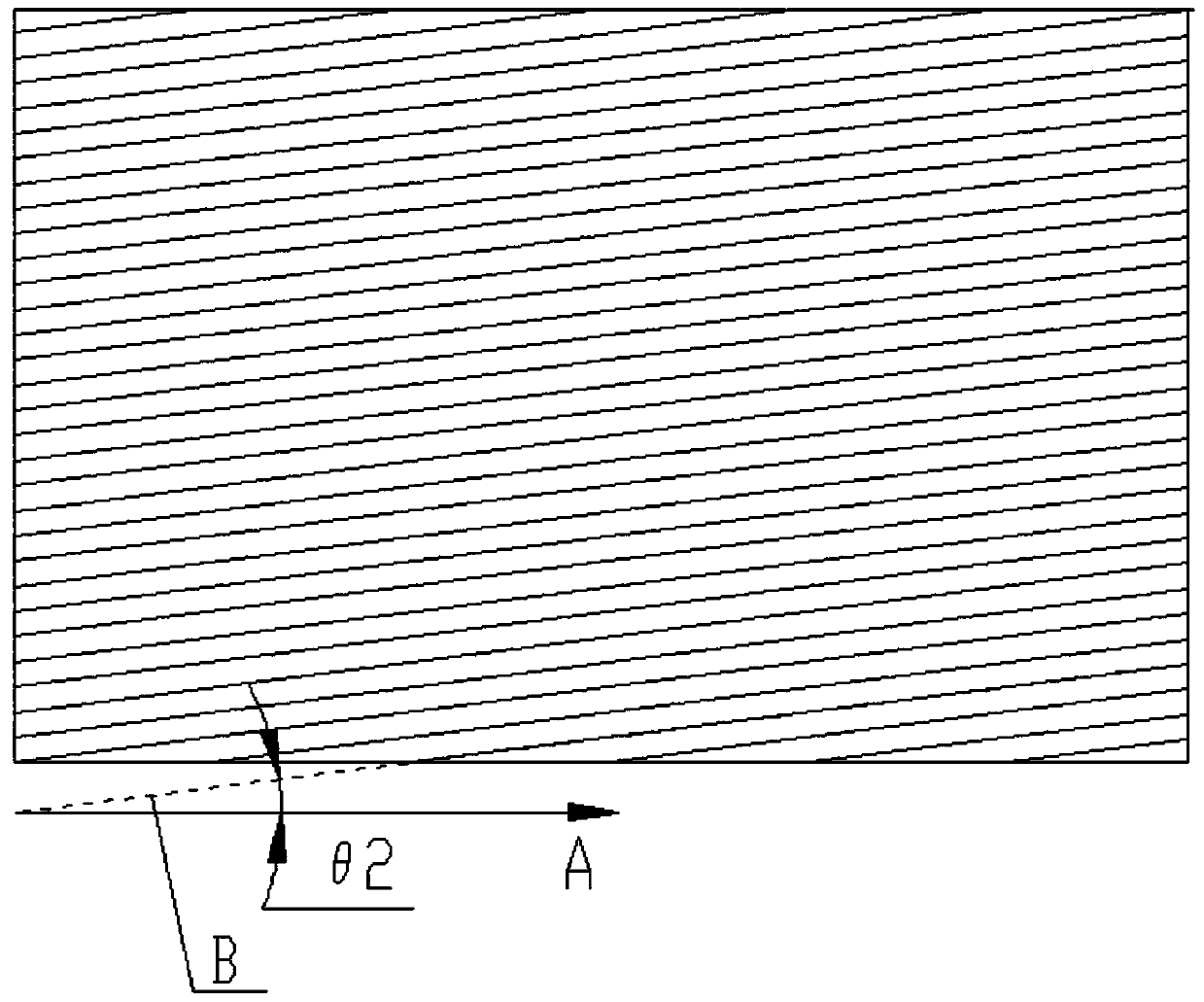

[0040] Such as figure 2 , image 3...

Embodiment 2

[0045] Such as figure 1 , figure 2 As shown, the laminating film for display includes the atomized layer film 1, the base film 3 and the prism layer film 2 arranged in sequence from top to bottom, and the atomized layer film 1, the base film 3 and the prism layer film 2 are bonded sequentially The glue 4 fits each other.

[0046] The atomized layer film 1 includes a polarizing film 11, and the upper surface of the polarizing film 11 has an atomized coating layer 12 with a haze of 86%. Laminating glue 4 is coated on the lower surface of the atomized layer film 1 for surface-to-surface bonding with the base film 3 .

[0047] The base film 3 is a 70 μm optical grade chemically treated PET film. The base film 3 is first pre-coated, and the upper and lower surfaces of the base film 3 are coated with a coating liquid composed of water-based polyurethane and a curing agent with a mass ratio of 20:1, and then the laminating glue 4 is coated.

[0048] Such as figure 2 , image ...

Embodiment 3

[0053] Such as figure 1 , figure 2 As shown, the laminating film for display includes the atomized layer film 1, the base film 3 and the prism layer film 2 arranged in sequence from top to bottom, and the atomized layer film 1, the base film 3 and the prism layer film 2 are bonded sequentially The glue 4 fits each other.

[0054] The atomized layer film 1 includes a polarizing film 11, and the upper surface of the polarizing film 11 has an atomized coating layer 12 with a haze of 90%. Laminating glue 4 is coated on the lower surface of the atomized layer film 1 for surface-to-surface bonding with the base film 3 .

[0055] The base film 3 is a 100 μm optical grade chemically treated PET film. The base film 3 is first pre-coated, and the upper and lower surfaces of the base film 3 are coated with a coating solution composed of water-based polyurethane and a curing agent with a mass ratio of 17:1, and then the laminating glue 4 is coated.

[0056] Such as figure 2 , ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com