Method and device for recycling waste circuit boards through ion liquid

A technology for waste circuit boards and ionic liquids, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as difficulty in gas volume control, difficulty in implementation, difficulty in regeneration, etc. The effect of subsequent production and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

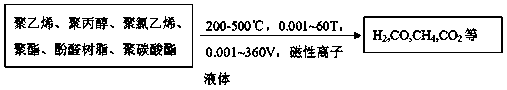

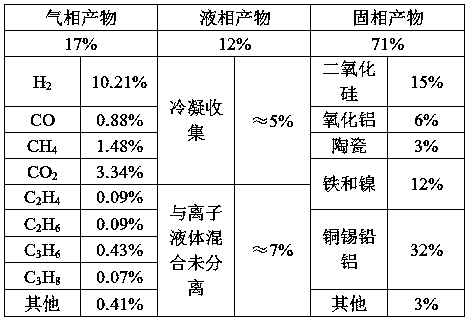

[0030] Embodiment 1: the processing object of this embodiment is the TV printed circuit board 100kg disassembled by a waste electric appliance recycling station, and the specific contents are as follows:

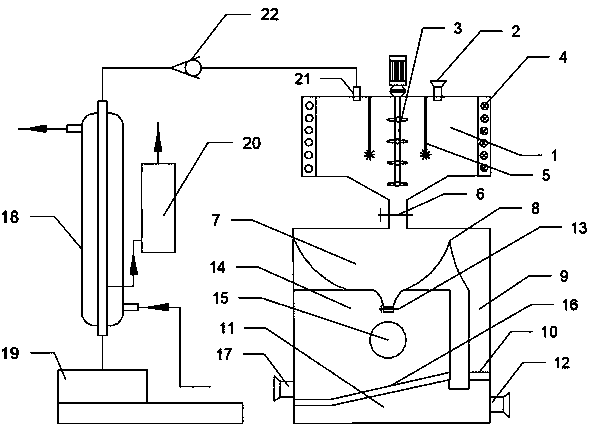

[0031] 1. If figure 1 As shown, the device of this embodiment includes a pyrolysis reactor 1, a solid-liquid separation device, a condenser 18, a condensable gas collection device 19, and a non-condensable gas collection device 20. The top of the pyrolysis reactor 1 is provided with a feed port 2, Gas outlet 21, the impeller stirrer 3 is arranged in the pyrolysis reactor 1, two inert electrodes 5 are arranged in the pyrolysis reactor 1, and are positioned at one side of the impeller stirrer, the electromagnetic generator 4 is arranged on the pyrolysis reactor 1, The magnetic field generated by the magnetic field generator covers the pyrolysis reaction space. A heater is arranged in the pyrolysis reactor 1. There is an outlet I6 at the bottom of the pyrolysis reactor 1. The ...

Embodiment 2

[0036] Embodiment 2: The processing object of this embodiment is 80 kg of printed circuit boards such as calculators and old-fashioned landlines disassembled by a certain waste electrical appliance recycling station. The specific contents are as follows:

[0037] 1. The structure of the device used in this embodiment is the same as in Embodiment 1;

[0038] 2. The specific operation and control process are as follows:

[0039] 80kg waste circuit boards are crushed with a universal crusher, crushed to a particle size of 2 mesh, and 180kg [Bmim]CoCl 4 The ionic liquid is mixed, and enters the pyrolysis reactor 1 from the feed port 2, and the impeller stirrer 3 is turned on, and the stirring rate is 60r / min; 10°C / min, when the temperature reaches 120°C, the electromagnetic generator 4 is turned on to generate a constant magnetic field of 1T, the inert electrode 5 is energized, and the voltage is constant at 10V, the condensing device 18 is turned on, and gas collection starts, w...

Embodiment 3

[0043] Embodiment 3: the processing object of this embodiment is 20kg of electronic calculator printed circuit boards disassembled by a waste electric appliance recycling station, and the specific contents are as follows:

[0044] 1. The structure of the device used in this embodiment is the same as in Embodiment 1, except that there is no magnetic field generator;

[0045] 2. The specific operation and control process are as follows:

[0046] Use a universal crusher to crush 20kg of waste circuit boards until the particle size is 50 mesh, and 100kg [Bmim]Fe 2 Cl 7 The ionic liquid is mixed, and enters the pyrolysis reactor 1 from the feed port 2, and the impeller stirrer 3 is turned on, and the stirring rate is 60r / min; 10°C / min, when the temperature reaches 120°C, the inert electrode 5 is energized, and the voltage is constant at 110V, the condensing device 18 is turned on, and gas collection starts, and when the temperature rises to 200°C, it enters the constant temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com