Automatic idling control method for digger engine

A technology of idle speed control and engine, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve the problems of large change in engine speed, increase fuel consumption, affect engine life and reliability, etc., to improve power matching, guarantee The effect of responsiveness and dynamics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: A method for automatic idle speed control of an excavator engine. The secondary target speed of the engine is set, and the secondary target speed is 50 to 300 rpm lower than the target speed in the working state; a high idle speed and a low idle speed are set, The high idle speed is 300-500 rpm higher than the low idle speed; set the pilot pressure threshold, the value range is 5-20 bar; set the first idle time between 0.5 and 5 seconds, and the second idle time Between 0.5 and 5 seconds; in the working state, detect the pilot pressure, when the pilot pressure is zero and lasts for the first idle time, adjust the engine to a high idle state, and continue to maintain the second idle time, adjust the engine to a low idle state ;In the state of high idle speed or low idle speed, when it detects that the pilot pressure is greater than zero and less than the pilot pressure threshold, adjust the engine to the sub-target speed, and when it detects that the pilot p...

Embodiment 2

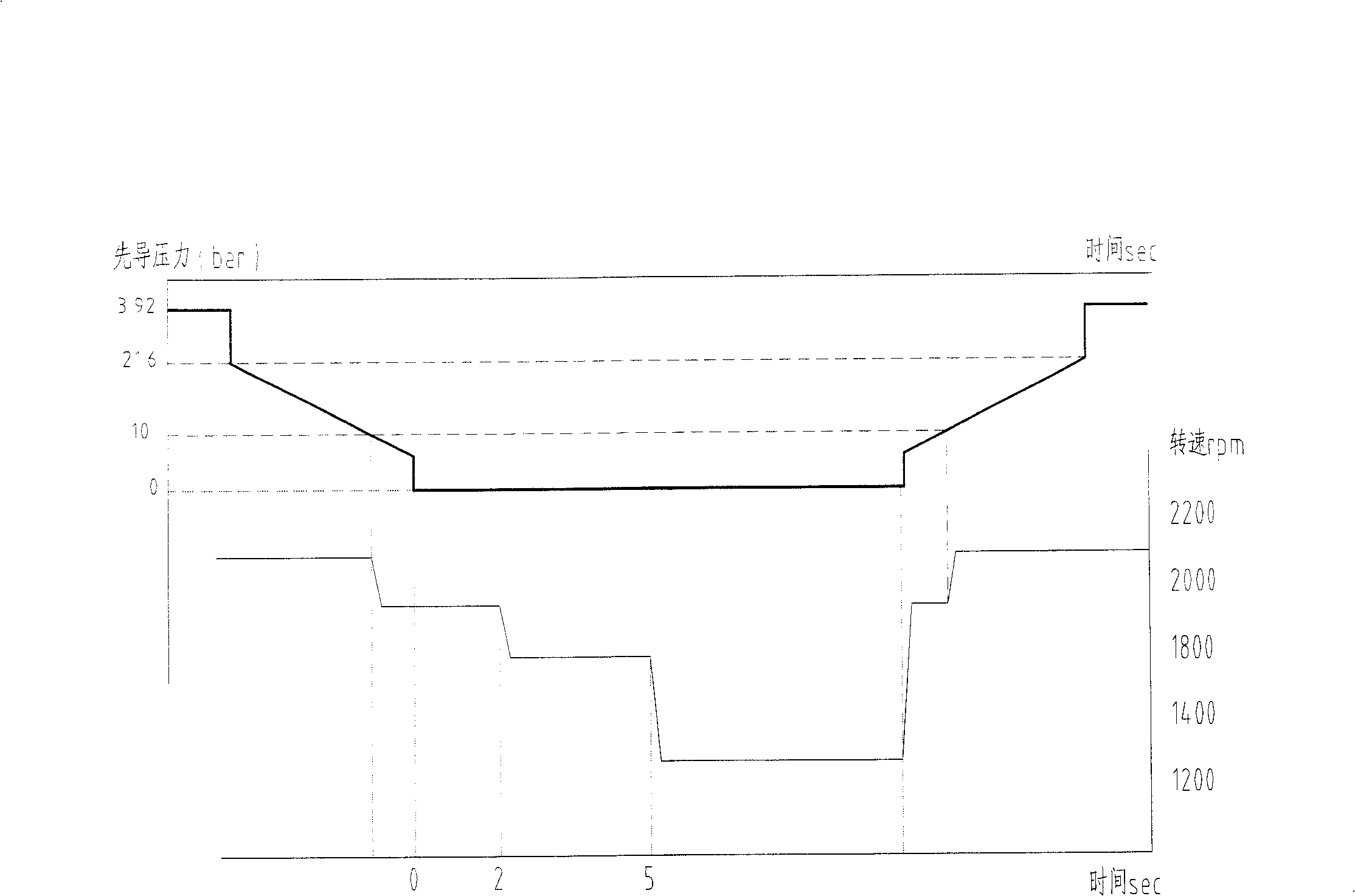

[0016] Embodiment two: see attached figure 1 As shown, an excavator engine automatic idle speed control method, the engine rated speed is 2100rpm, the target speed when the throttle gear is the largest is taken as 2100rpm, the secondary target speed is taken as 2000rpm, the high idle speed is taken as 1700rpm, and the low idle speed is taken as 1300rpm, the threshold value of the pilot pressure under light load is 10bar.

[0017] When the controller detects that all the pilot pressures are less than 10bar, immediately reduce the engine speed from the target speed 2100rpm to the sub-target speed 2000rpm, when all the pilot pressures are zero and last for 2 seconds, adjust the engine to enter the high idle speed 1700rpm , when the controller detects that all the pilot pressures are zero and the high idle state lasts for 3 seconds, adjust the engine to enter the low idle speed 1300rpm, when the engine is in the high idle state or low idle state, the controller detects that there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com