Membrane type hydraulic vibration exciter

A hydraulic exciter and membrane technology, applied in the direction of fluid pressure actuating devices, etc., can solve the problems that the air pressure and hydraulic exciters cannot be frequency-modulated and amplitude-modulated, and the mechanical exciters cannot be stopped for amplitude modulation, etc., to achieve the excitation force. Evenly distributed, easy to synchronize and parallel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

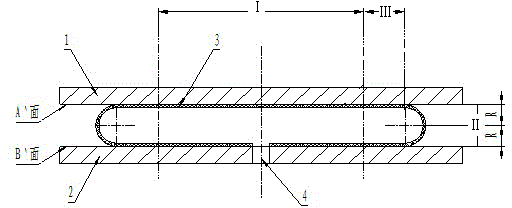

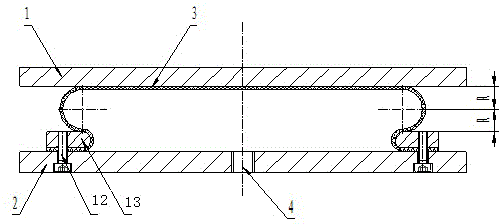

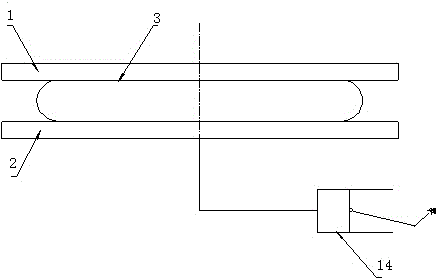

[0035] The film type hydraulic exciter is composed of two parallel rigid plates 1, 2, and a film 3 made of flexible material that does not leak and is not easy to elongate. Lun, such as figure 1 , the opposite sides of rigid plate 1 and rigid plate 2 are A` and B` respectively, the distance between A` and B` is very small, preferably <30mm, and the two rigid plates can be perpendicular to A` relative motion.

[0036] Surface A` and surface B` can be divided into three areas:

[0037] zone I in constant contact with the membrane 3 or liquid;

[0038] zone II which is never in contact with the membrane 3 or the liquid;

[0039] Other areas III.

[0040] Area Ⅰ and area Ⅱ are not connected, and the film 3 is only in the area Ⅰ and the rigid plate is sealed and connected. The connection method is bonding, flange 13 compression connection or only contact but not fixed, that is, with the rigid plate provided with the channel 4, In the non-channel 4 area, the membrane 3 is bonde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com