Lubrication oil ageing simulation assessment method

A technology of lubricating oil and metal catalyst, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to simulate the oxidation process of lubricating oil, long test period, etc., and achieve the effect of strong practical promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

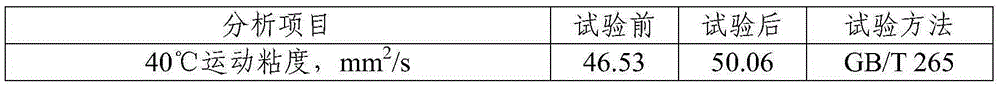

[0028] Follow the steps below to test the performance of lubricating oil:

[0029] (1) Take ordinary anti-wear hydraulic oil with quality level L-HM46 and copper sheet with a thickness of 0.10-0.12mm, a width of 15mm, and a length of 51mm, and test the performance parameters;

[0030] The performance parameters include: the viscosity, chroma, acid value, filterability, sludge content of the anti-wear hydraulic oil, and the quality of the copper sheet;

[0031] (2) Add 10% deionized water by mass percentage to the anti-wear hydraulic oil, add the copper sheet, feed 0.7MPa oxygen, run continuously at 150°C until the oxygen pressure drops by 20%, and then detect the The above performance parameters;

[0032] (3) Calculate the difference between the performance parameters obtained by the two tests and the time of continuous operation, and evaluate the oxidation resistance of the lubricating oil according to the difference.

[0033] The test results are shown in Table 1.

[0034...

Embodiment 2

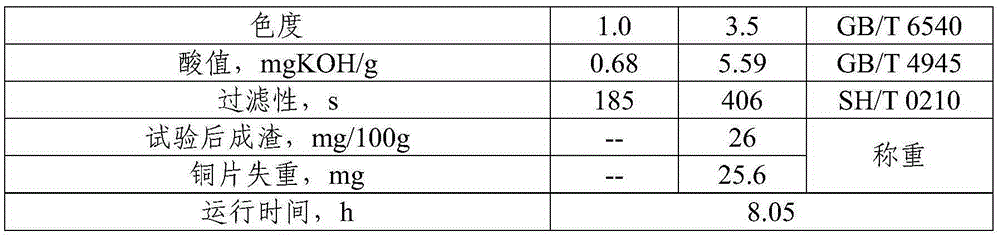

[0038] Follow the steps below to test the performance of lubricating oil:

[0039] (1) Take the high-pressure anti-wear hydraulic oil of brand A whose quality level is L-HM46, and copper and steel sheets with a thickness of 0.10-0.12mm, a width of 15mm, and a length of 51mm, and test the performance parameters;

[0040] The performance parameters include: the viscosity, chroma, acid value, filterability, sludge content, and liquid phase corrosion of the anti-wear hydraulic oil, as well as the quality, appearance, and corrosion level of the copper and steel sheets;

[0041] (2) Add 5% synthetic seawater by mass percentage to the anti-wear hydraulic oil, add the copper sheet and steel sheet, feed 0.8MPa oxygen, run continuously at 155°C until the oxygen pressure drops by 20%, and then again Detect said performance parameters;

[0042] (3) Calculate the difference between the performance parameters obtained by the two tests and the time of continuous operation, and evaluate the ...

Embodiment 3

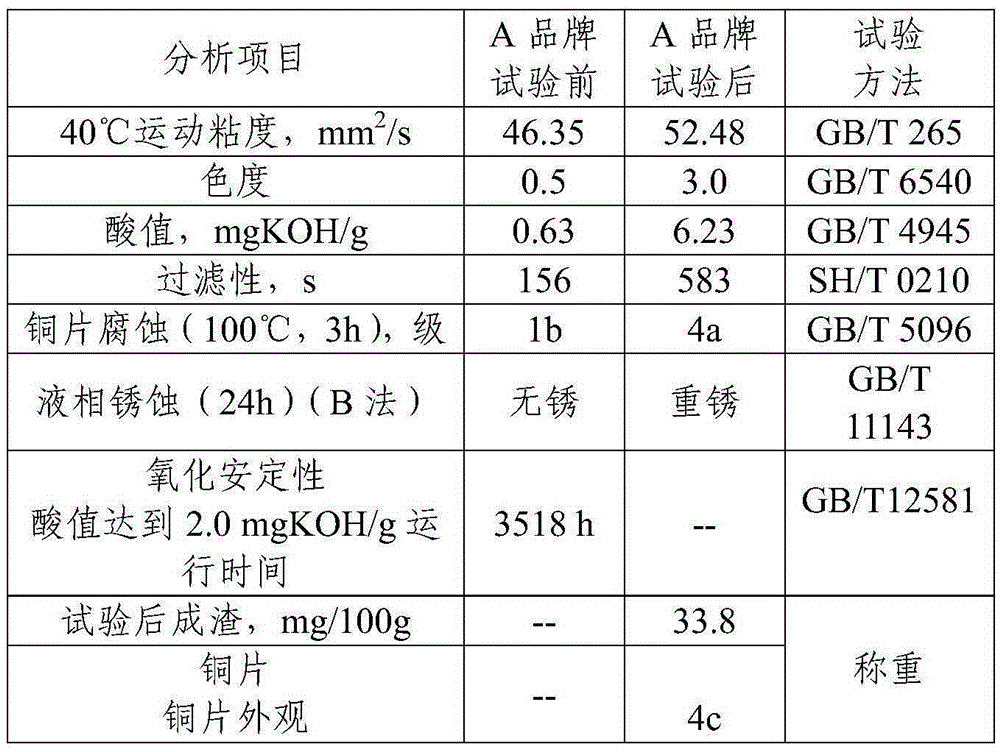

[0048] Follow the steps below to test the performance of lubricating oil:

[0049] (1) Take high-pressure anti-wear hydraulic oil of brand B whose quality level is L-HM46, and copper and steel sheets with a thickness of 0.10-0.12mm, a width of 15mm, and a length of 51mm, and test the performance parameters;

[0050] The performance parameters include: the viscosity, chroma, acid value, filterability, sludge content, and liquid phase corrosion of the anti-wear hydraulic oil, as well as the quality, appearance, and corrosion level of the copper and steel sheets;

[0051](2) Add 5% synthetic seawater by mass percentage to the anti-wear hydraulic oil, add the copper sheet and steel sheet, feed 0.8MPa oxygen, run continuously at 155°C until the oxygen pressure drops by 20%, and then again Detect said performance parameters;

[0052] (3) Calculate the difference between the performance parameters obtained by the two tests and the time of continuous operation, and evaluate the oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com