Patents

Literature

30results about How to "Overcome the failure rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

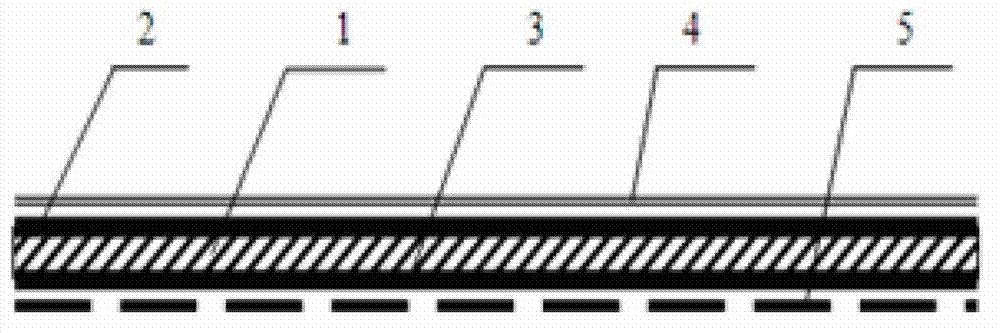

Pre-coating film without primer coating, two-way stretch polypropylene film thereof and preparation method of polypropylene film

ActiveCN102873953AEliminate pollutionNo adhesionSynthetic resin layered productsFlat articlesLinear low-density polyethyleneSurface layer

Owner:KANGDE XIN COMPOSITE MATERIAL CO LTD

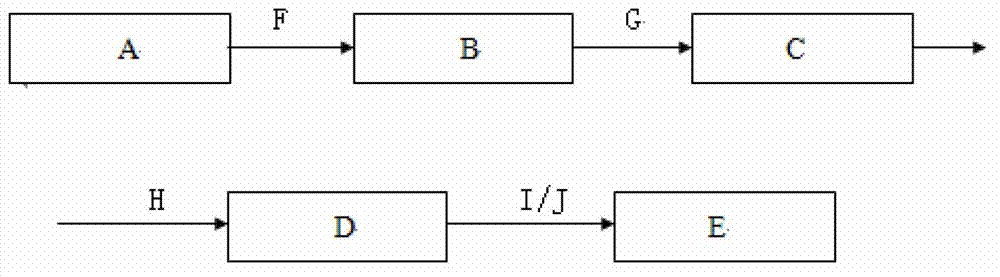

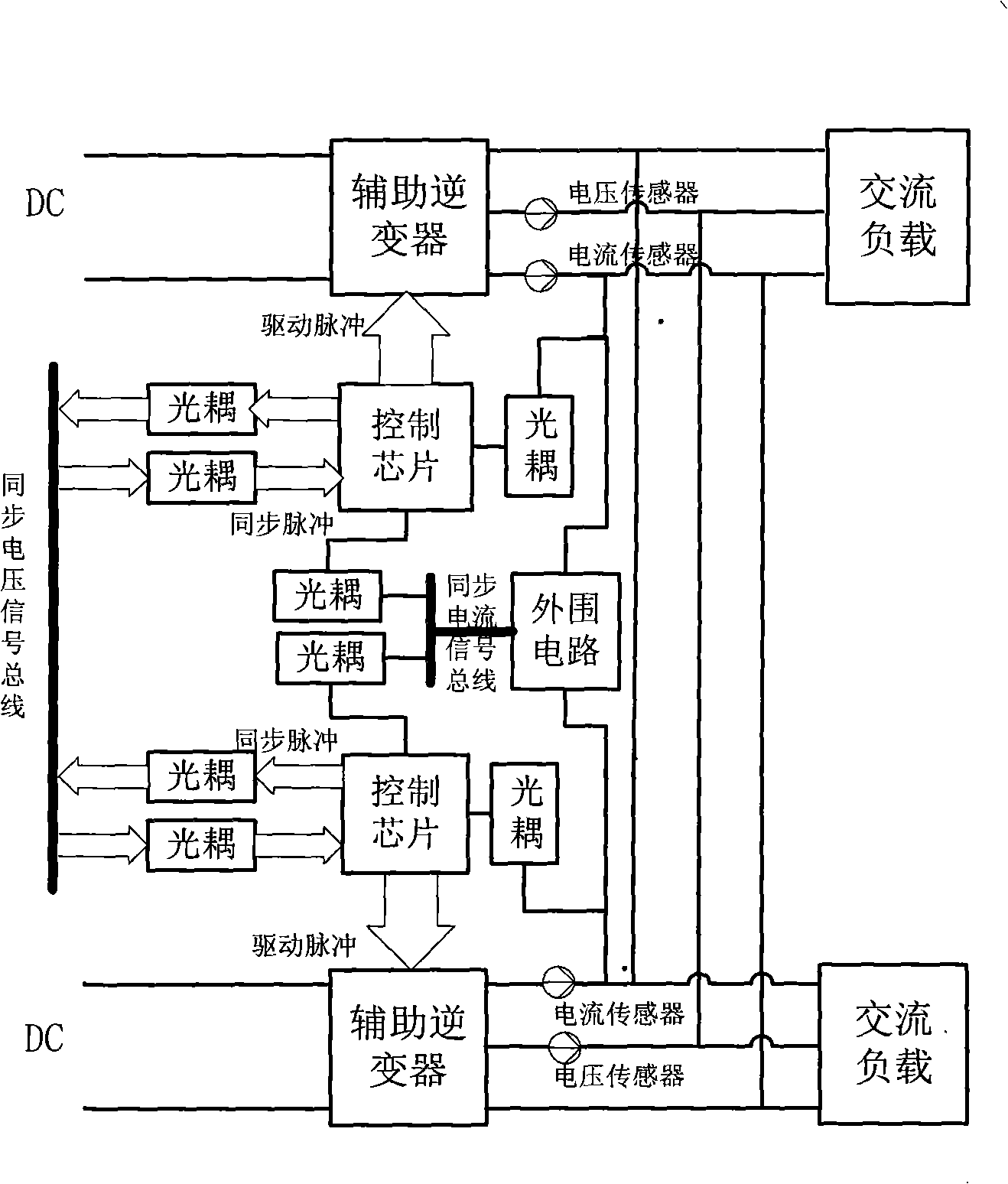

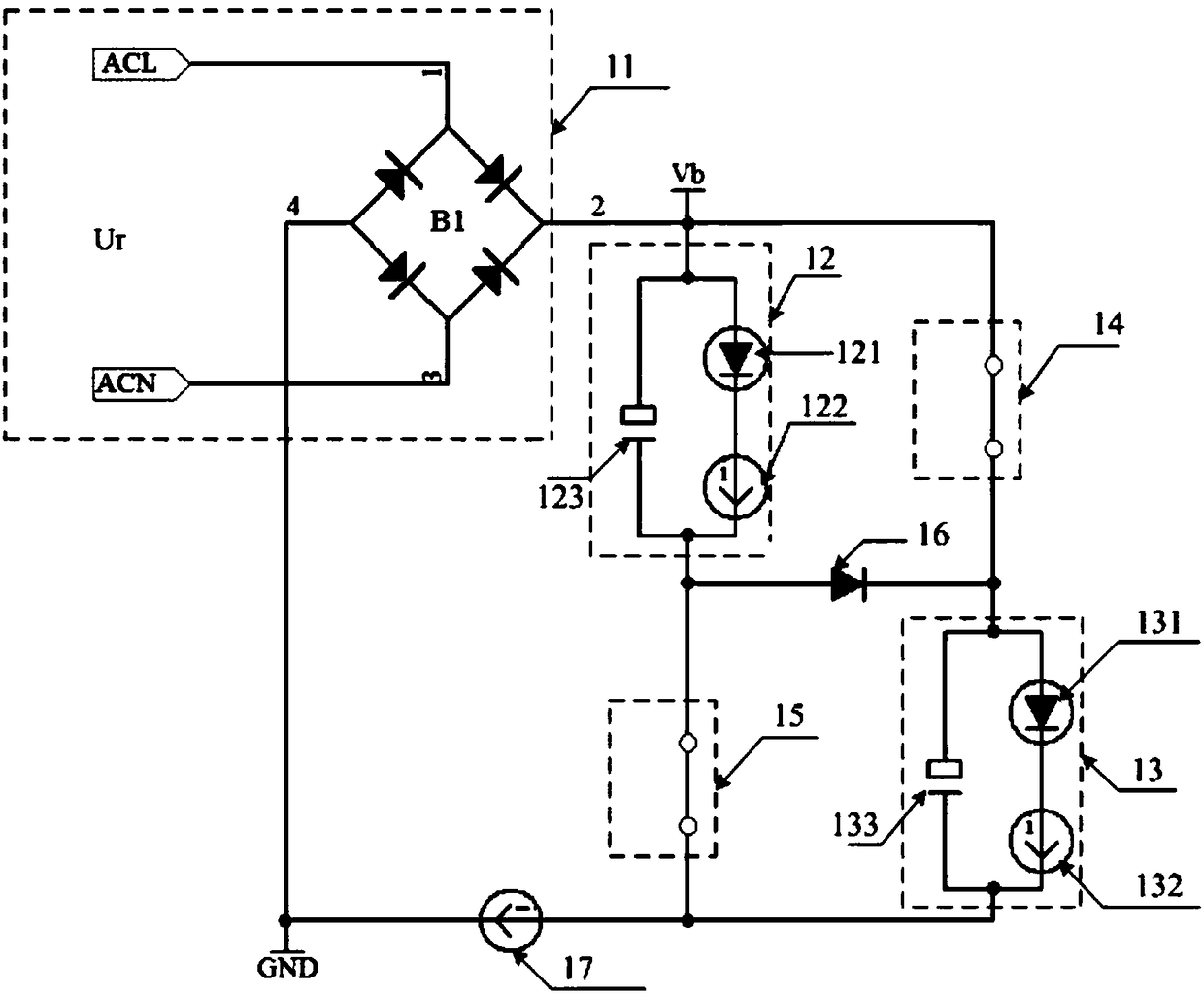

Light rail vehicle auxiliary inverse power supply parallel device and control method thereof

InactiveCN101259829AOvercome speedOvercome the failure rateSingle network parallel feeding arrangementsElectric powerElectricityEngineering

The invention discloses a parallel device for auxiliary inverter supply of a light rail vehicle and a control method. The device can unceasingly and reliably provide electricity to the light rail vehicle; two sets of auxiliary inverter supplies connected in parallel can be directly connected in parallel through wires. The method for realizing the parallel connection replaces the original method in which the auxiliary inverter supplies of the traditional light rail vehicle are connected in parallel through a contactor to supply the electricity to the load. When one of the auxiliary inverter supplies malfunctions, a control circuit blocks the drive pulse of the malfunctioned auxiliary inverter supply and stops the operation of the malfunctioned auxiliary inverter supply according to programmed controlling information beforehand, however, the load can be still electrified by the normal auxiliary inverter supply, thus realizing the unceasing power supply and enhancing the reliability of the whole system.

Owner:BEIJING JIAOTONG UNIV +1

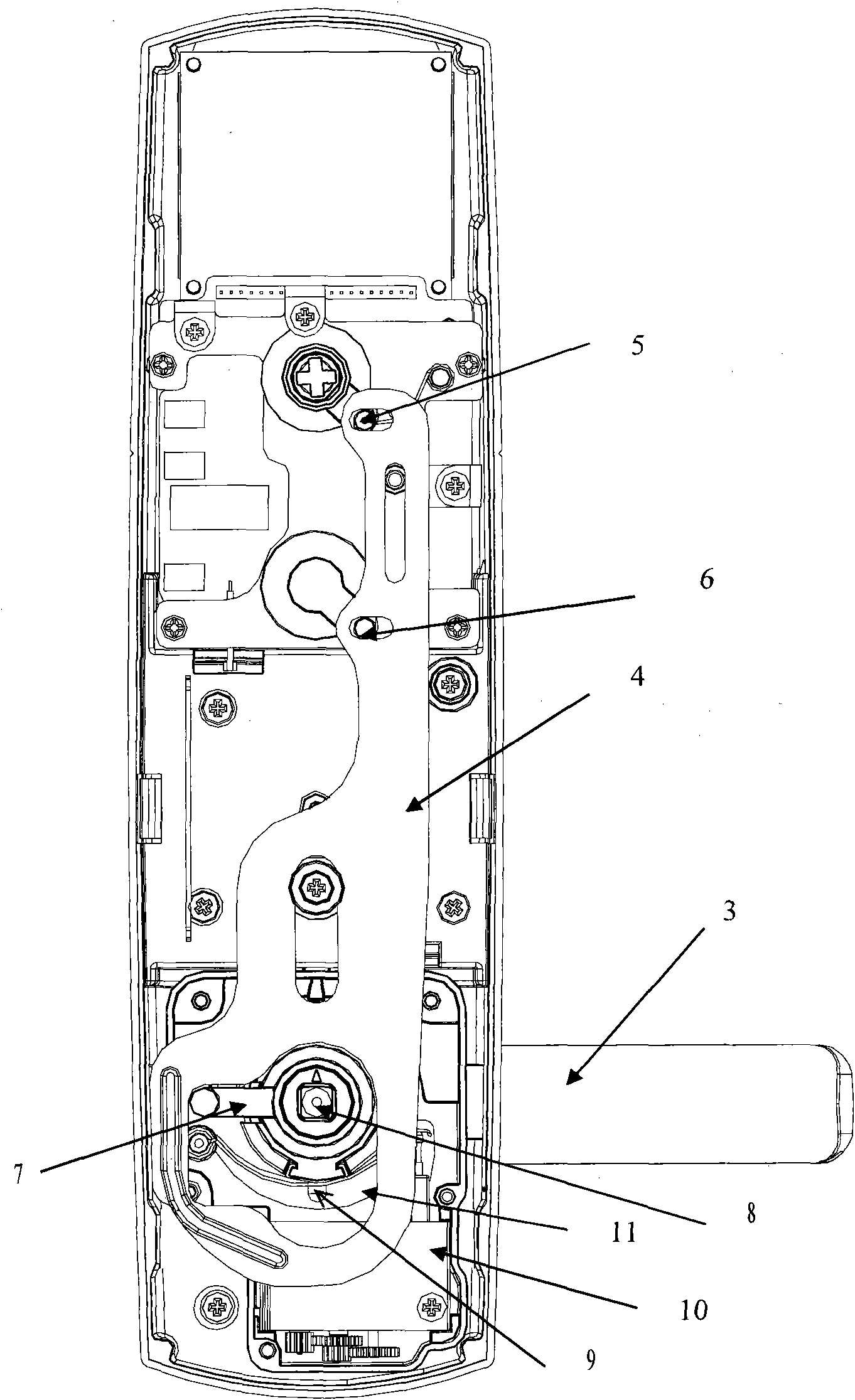

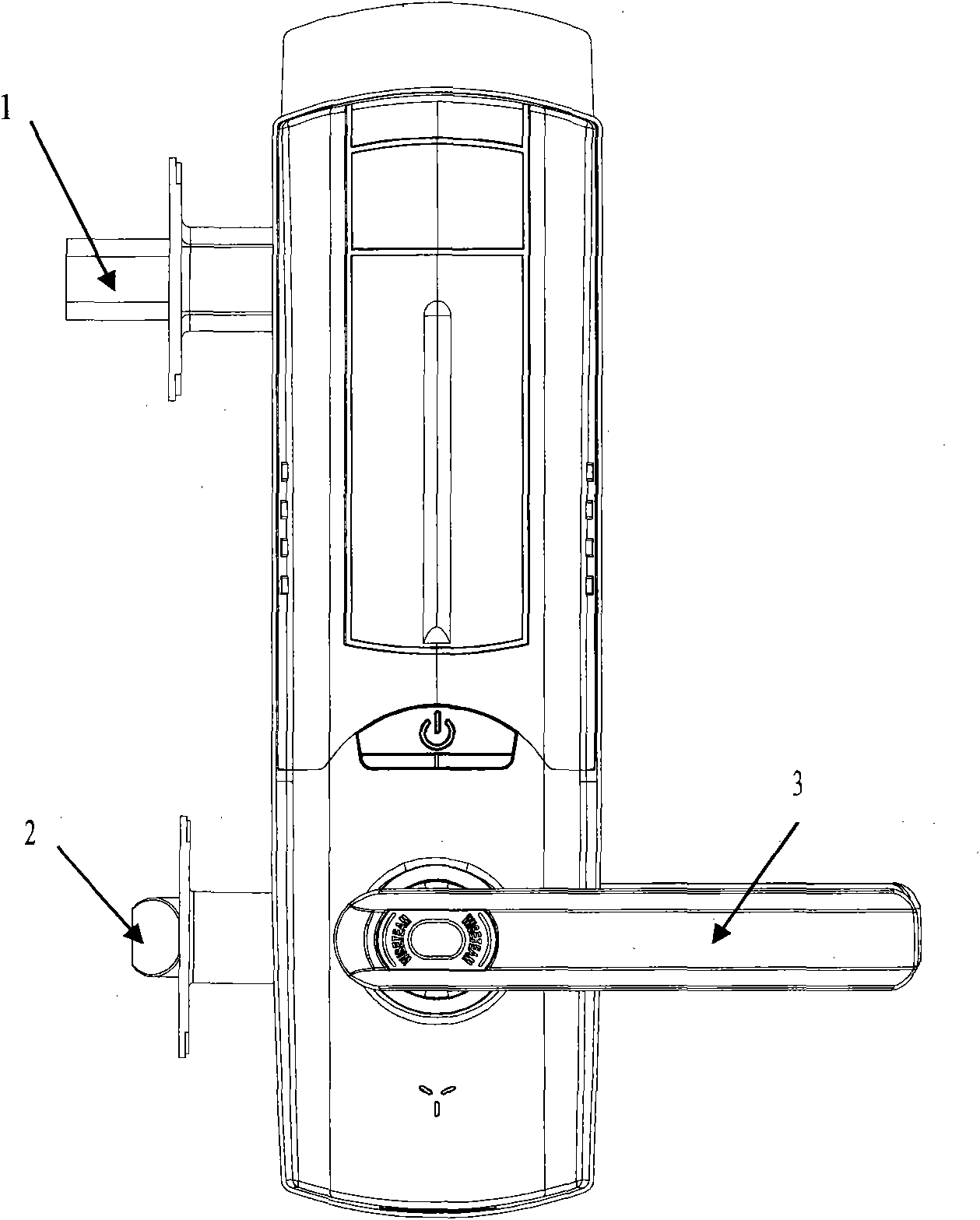

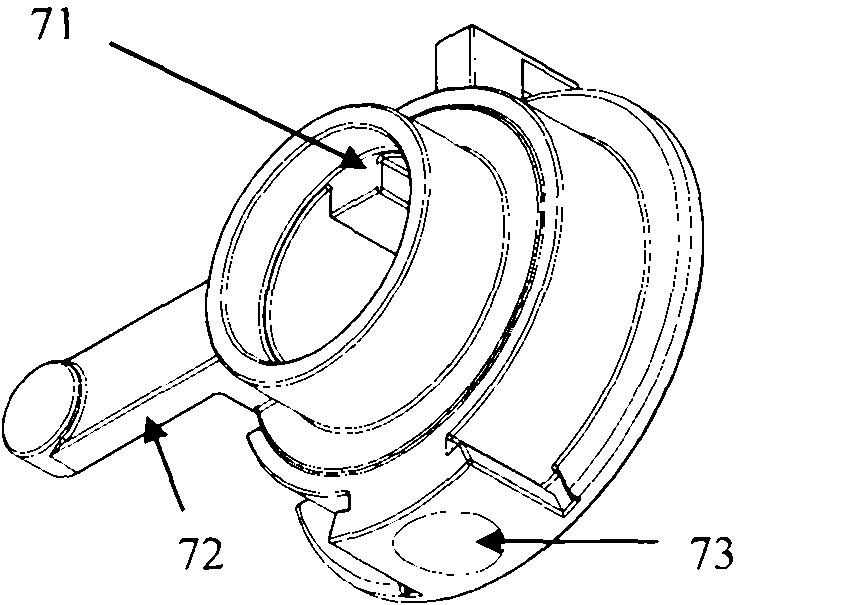

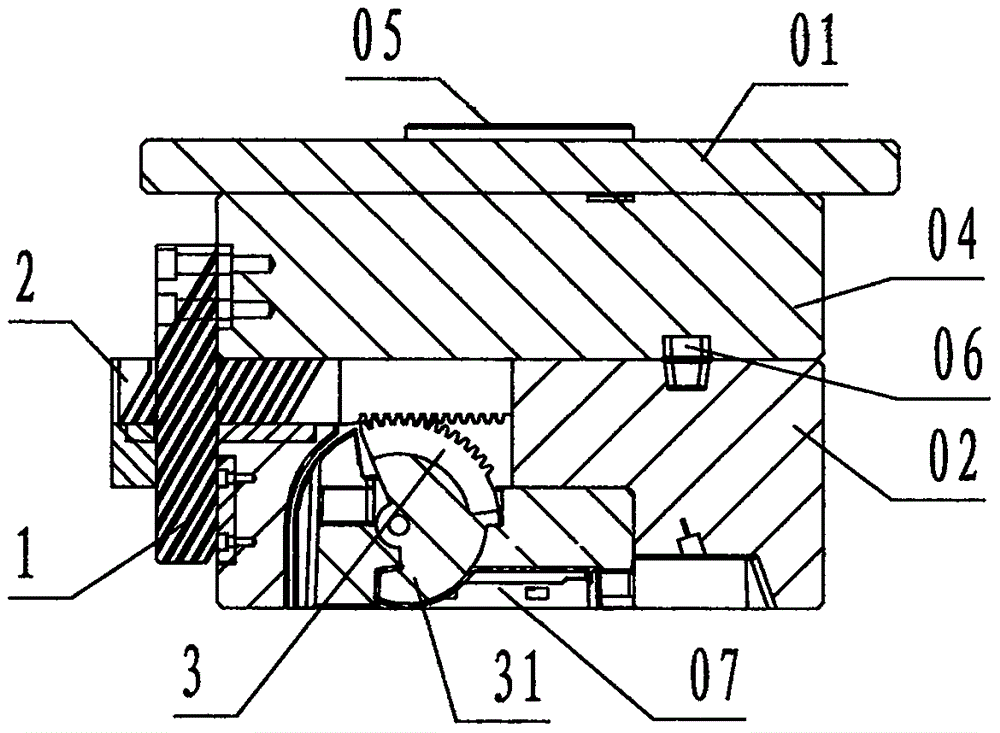

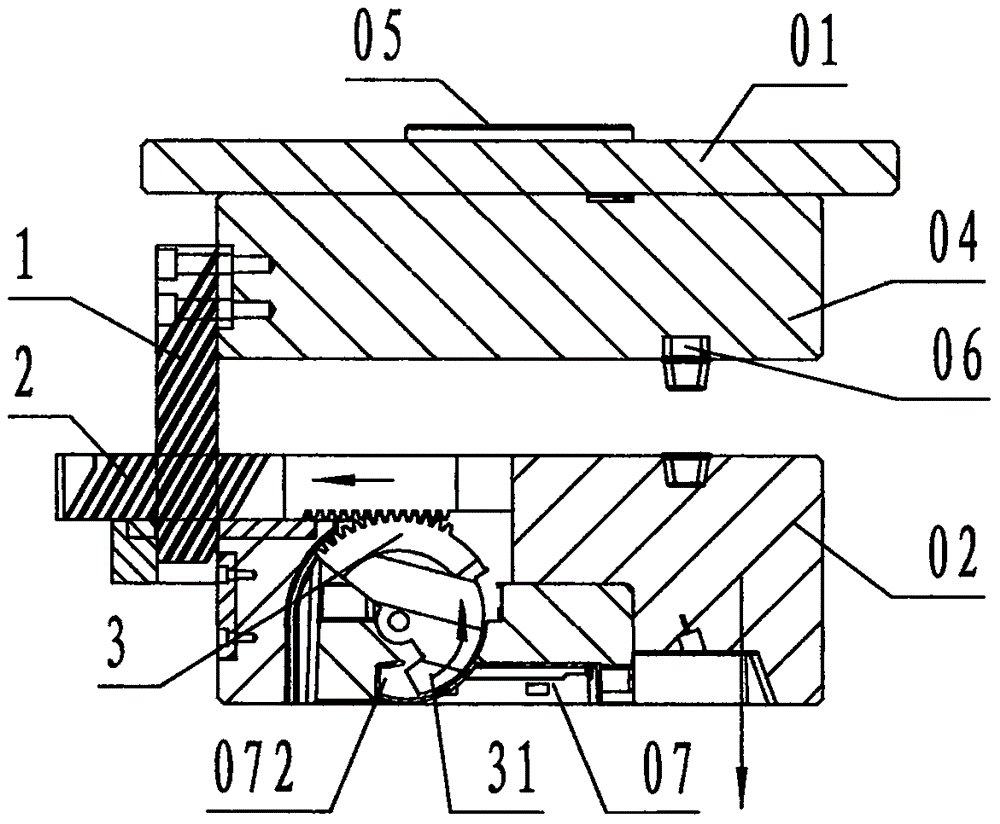

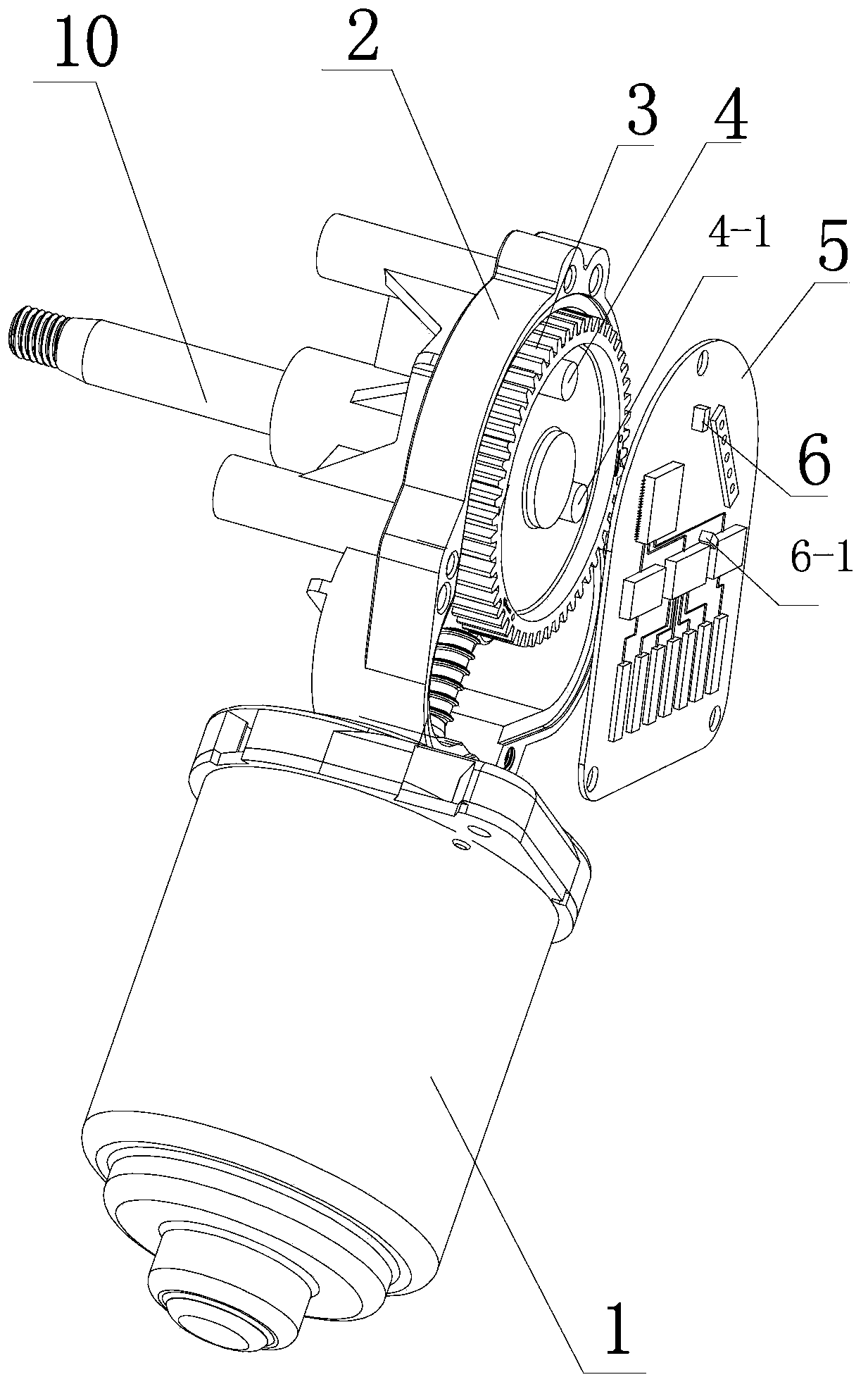

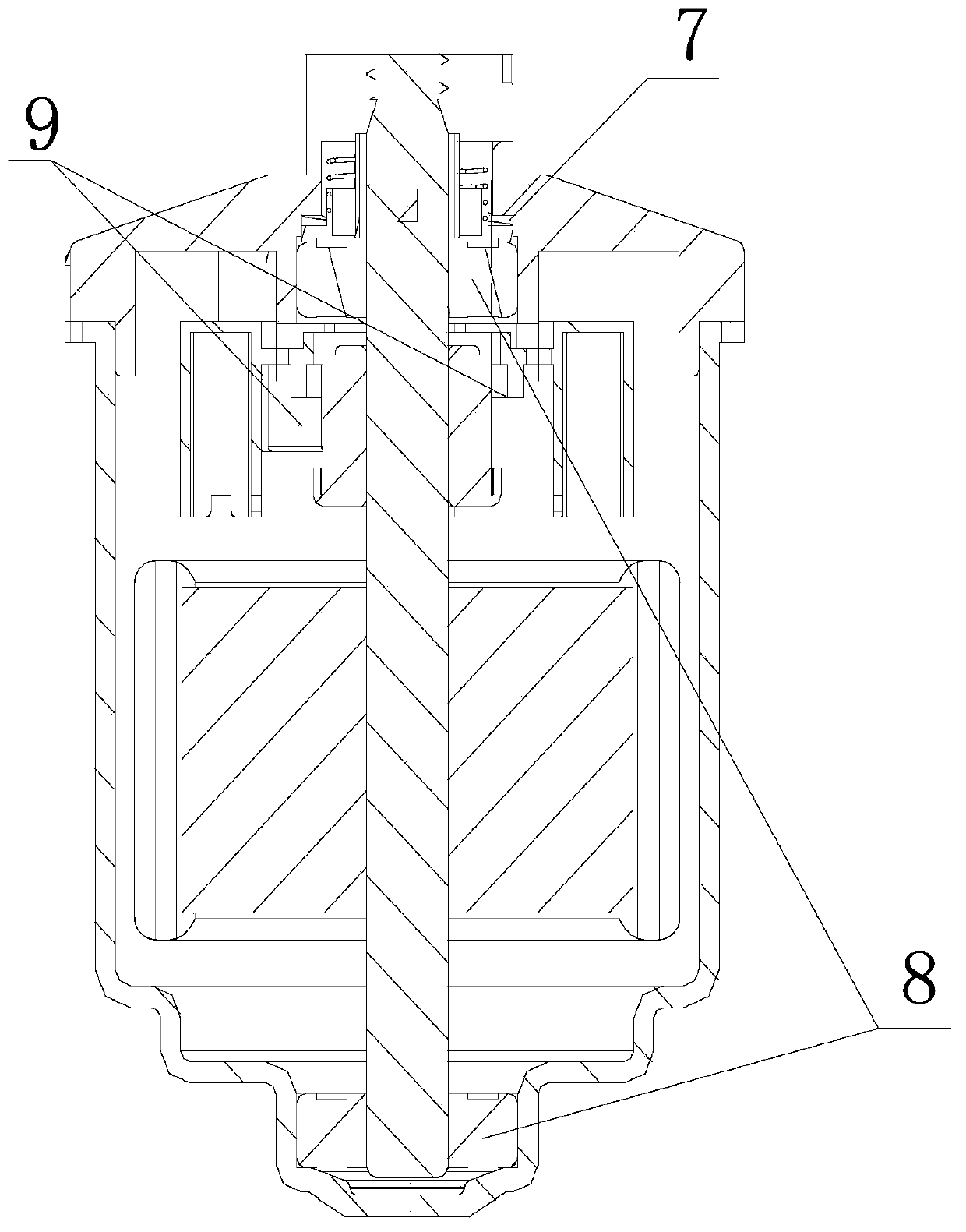

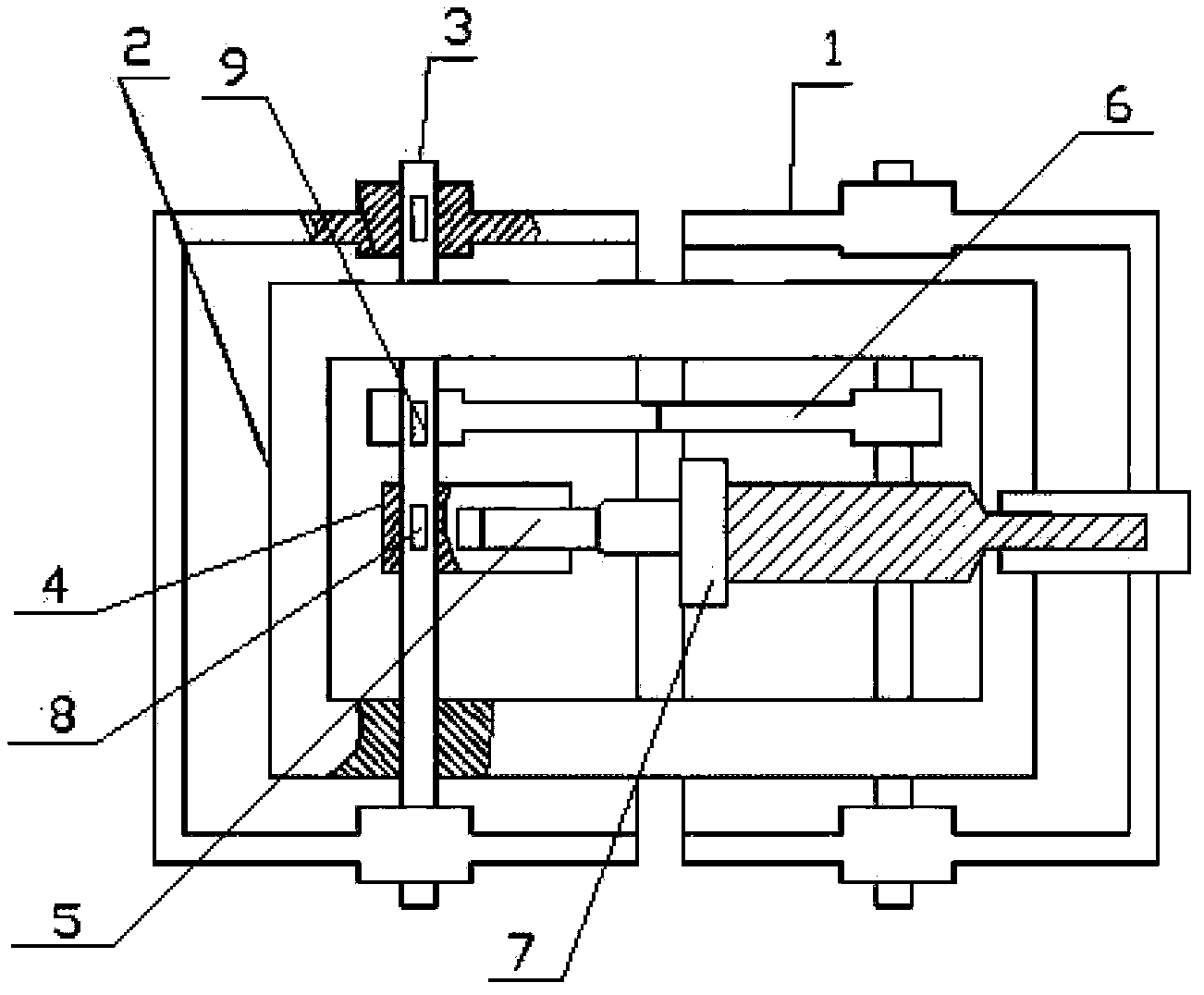

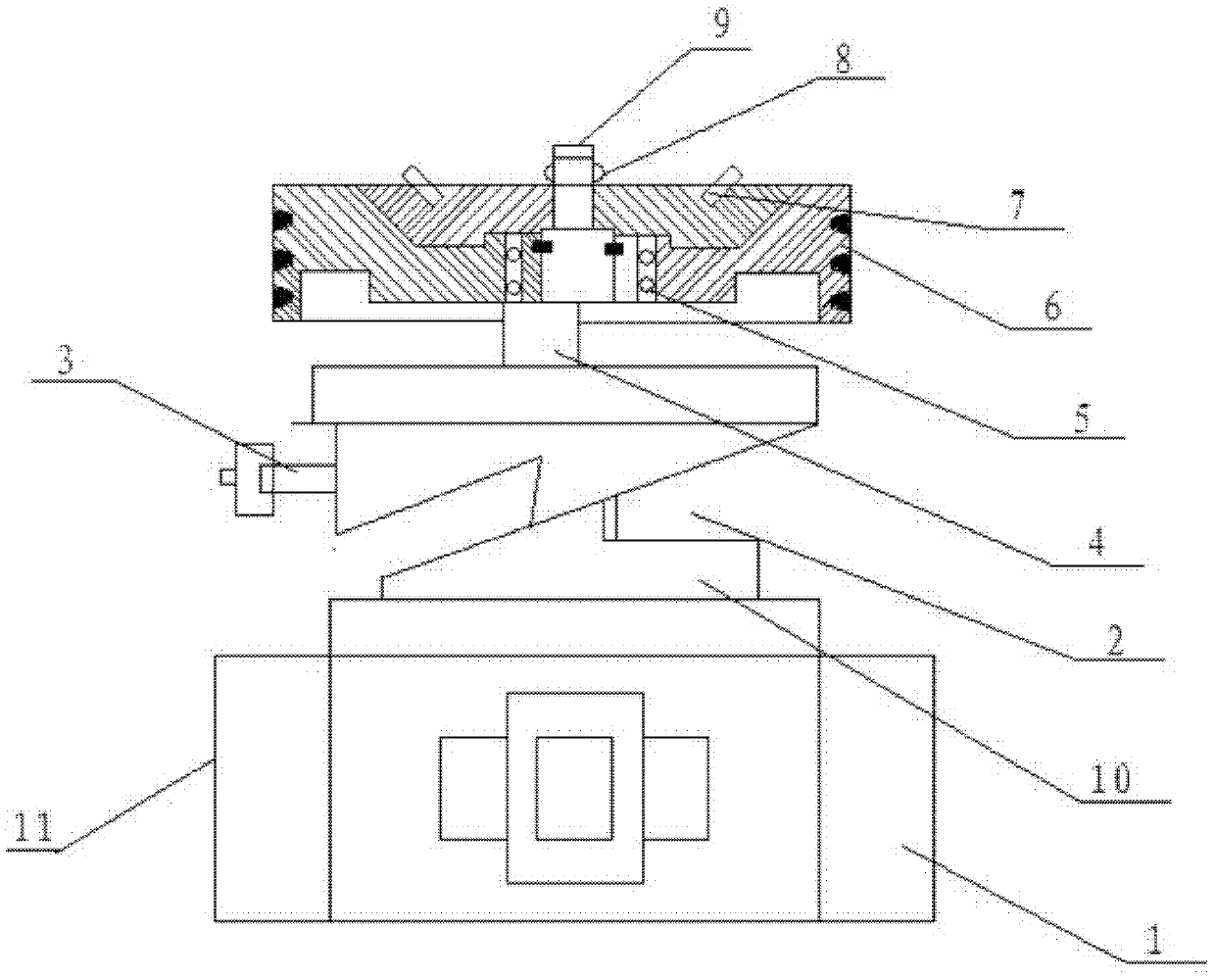

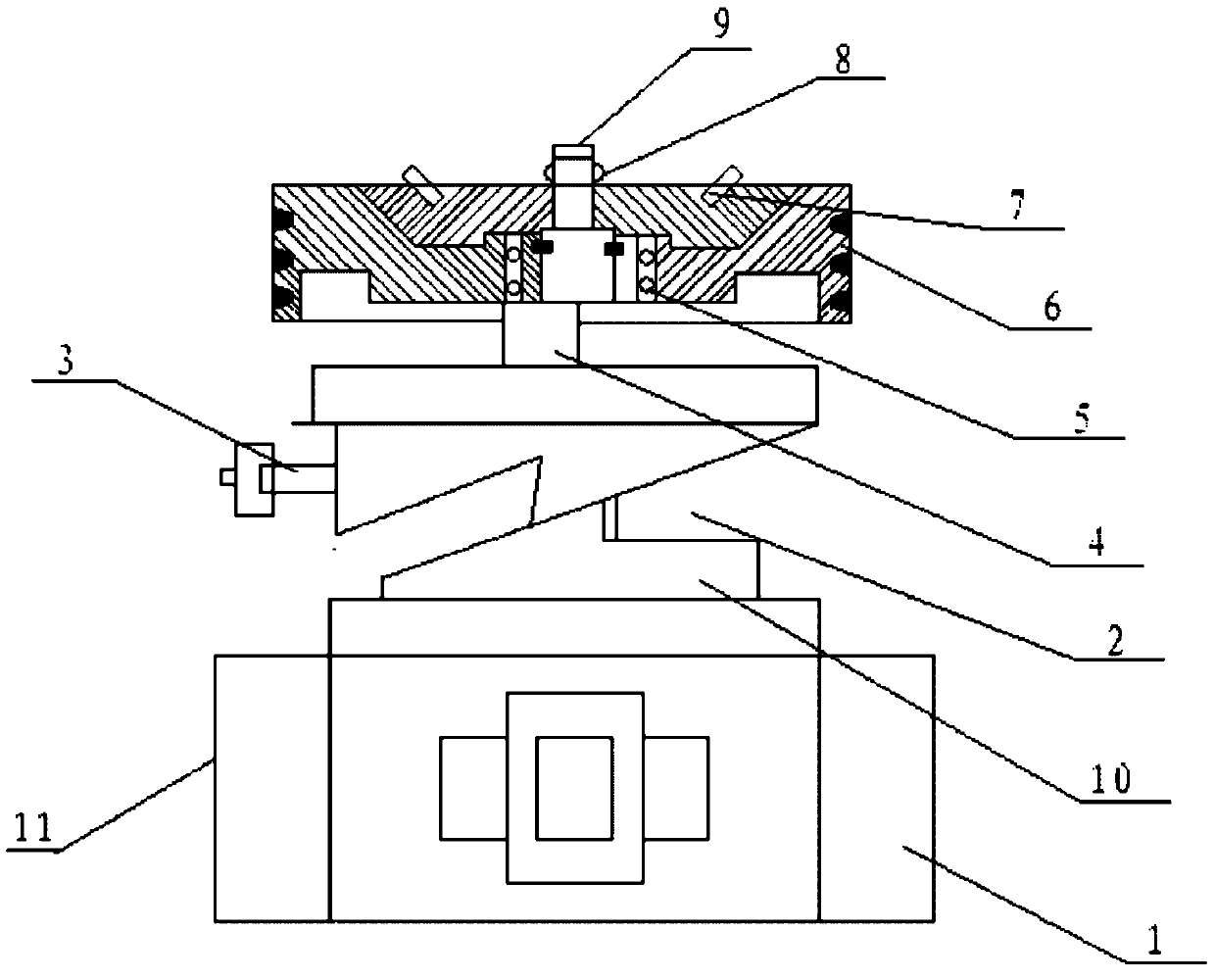

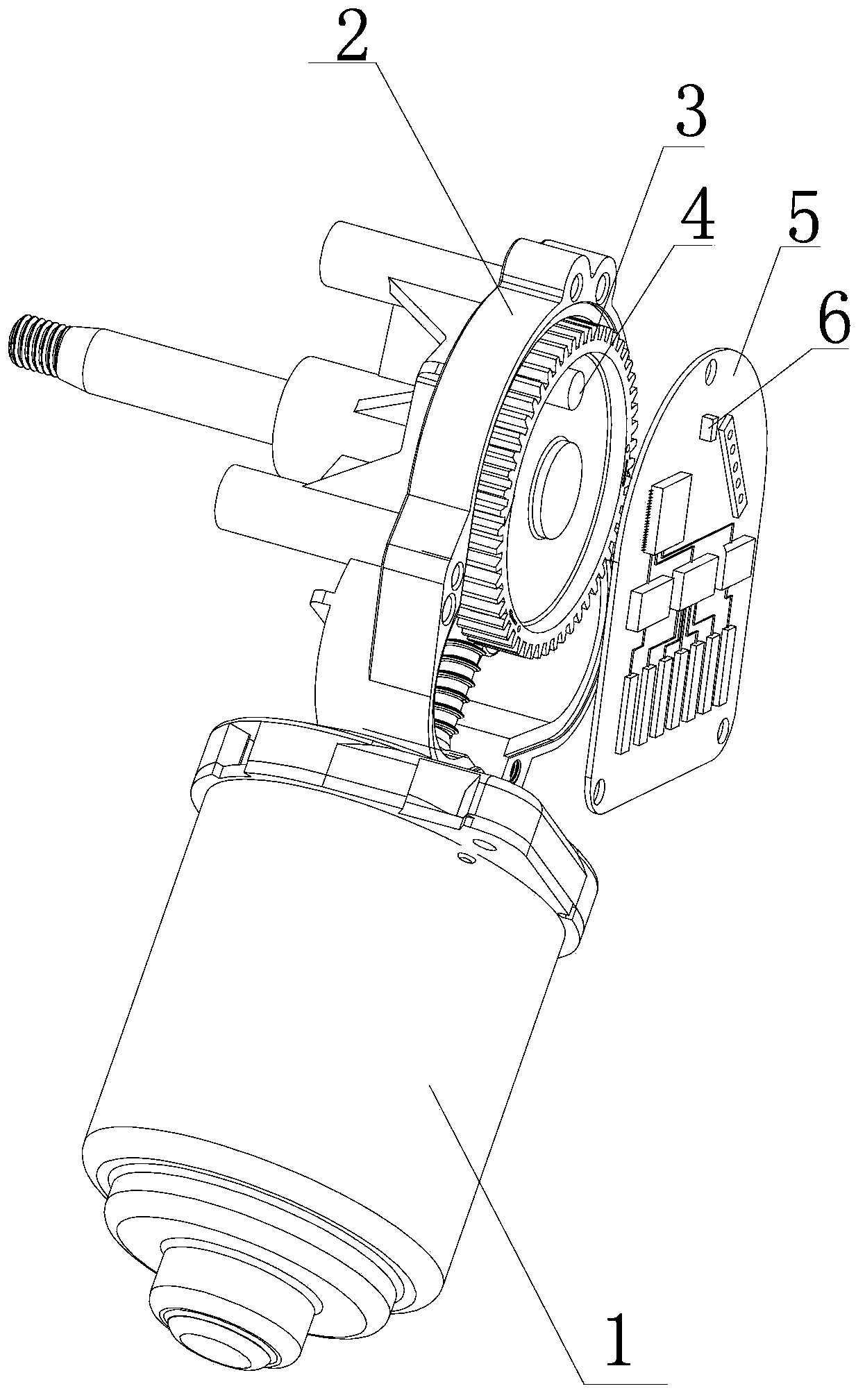

Door lock

InactiveCN102383666ASimple structureEasy to operateNon-mechanical controlsElectric permutation locksControl circuitElectric signal

An embodiment of the invention discloses a door lock. When fingerprints of a user are verified by a fingerprint verifying system 12, a control circuit in the fingerprint verifying system 12 sends out electric signals to a single motor 10 in the door lock so as to push a slide rail piece 11 and control positions of a pin 9 of a gear device to realize gear shift, and a handle 3 can be mechanically pressed to rotate in place, so that a locking spring bolt 1 can retract into the door lock, and the door lock is unlocked, and further, the door lock can be locked when the handle 3 is lifted outside a door. The door lock can be unlocked mechanically under driving of the single motor, so that electric energy is saved, the structure of the door lock is simpler as compared with a fingerprint verification double-bolt American door lock in the prior art, and probability of failure is decreased by the aid of the single motor. Besides, the door lock utilizes the model integrating gear parts in the prior art with a door opening shaft, brings great convenience for quick switching of leftwards opening and rightwards opening, and accordingly, is simple and convenient in operation and humanized in design.

Owner:上海威士迪科技股份有限公司

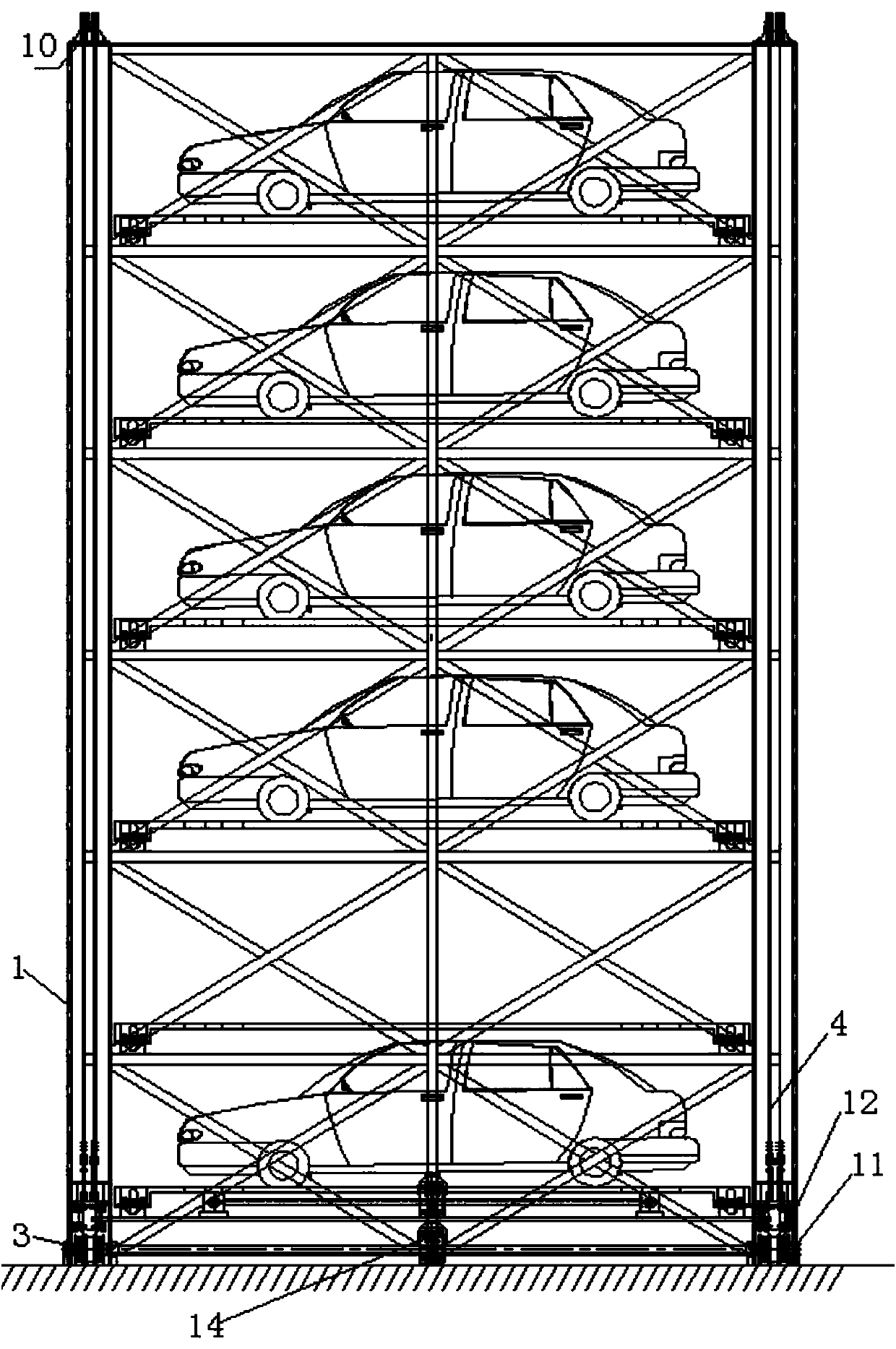

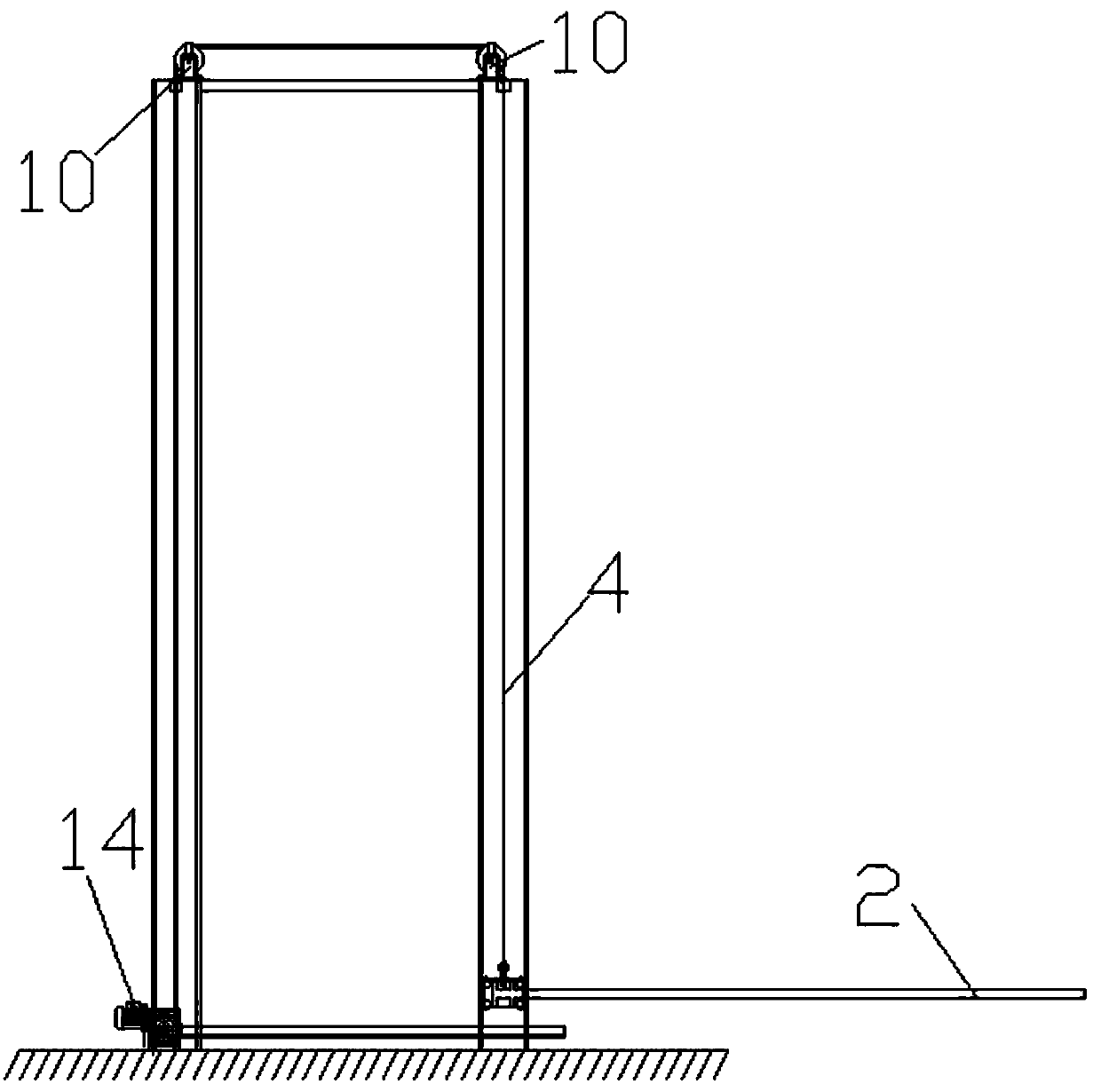

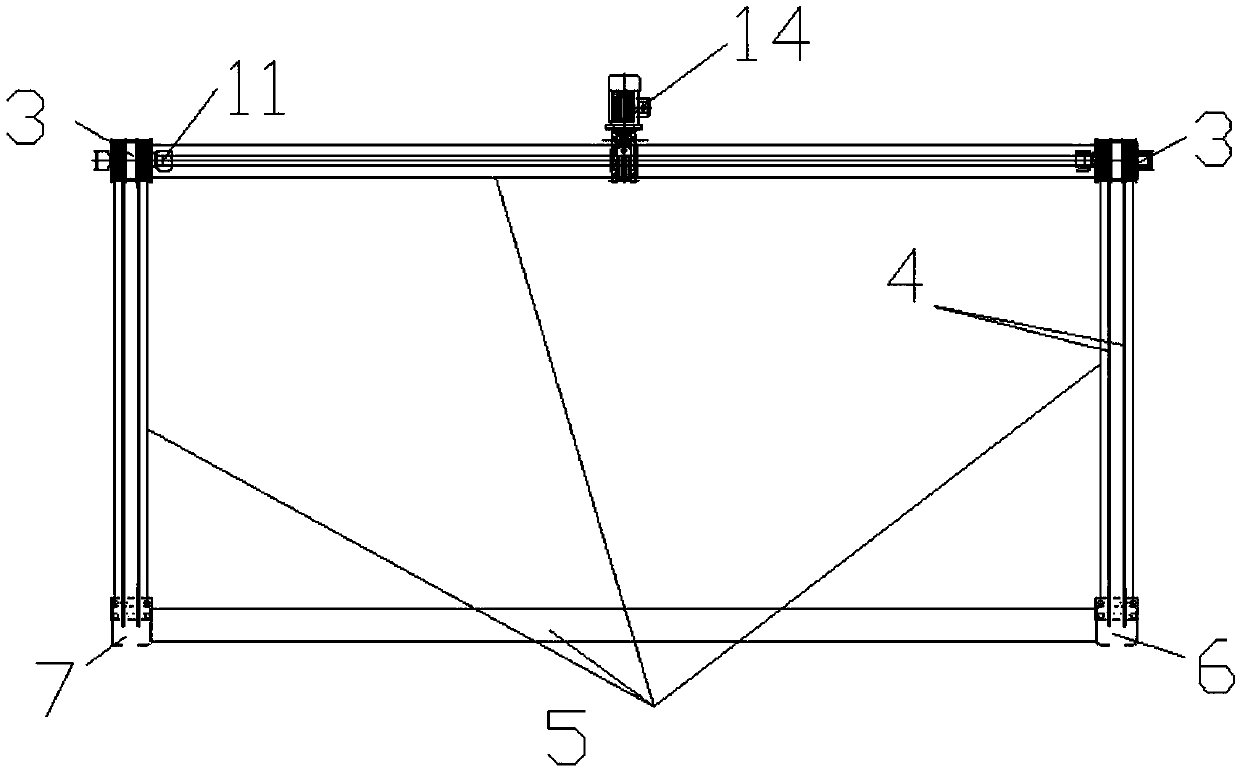

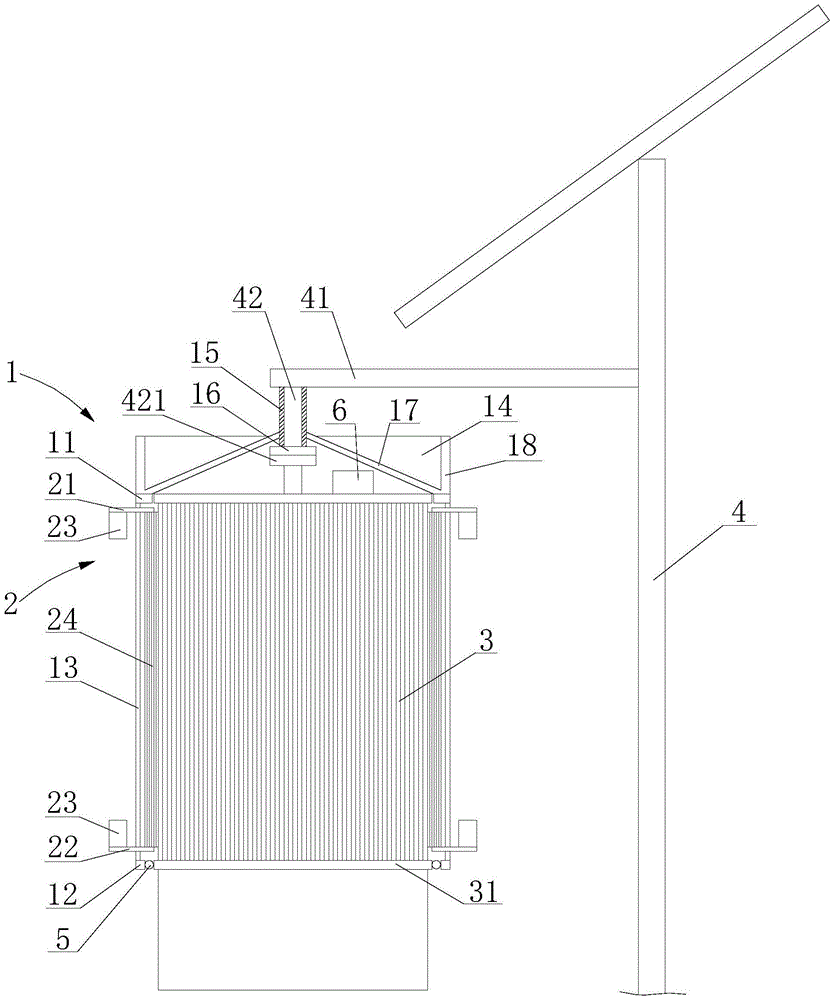

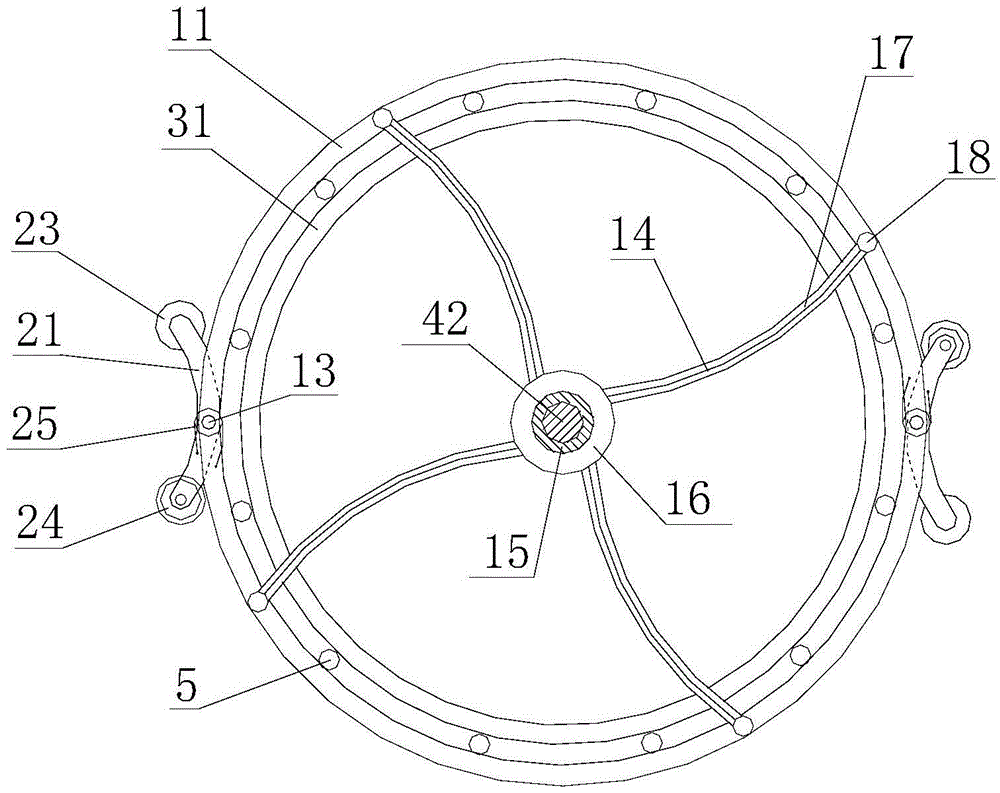

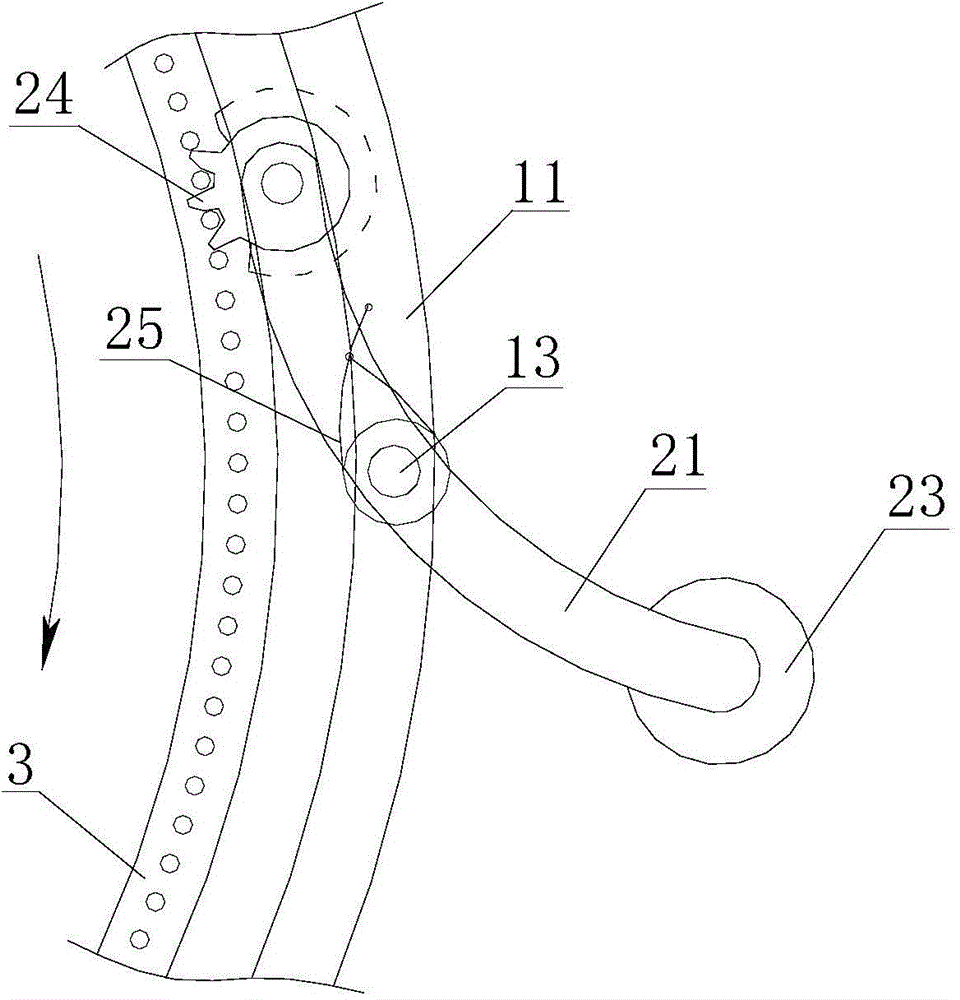

Steel cable towed type three-dimensional parking garage

The invention discloses a steel cable towed type three-dimensional parking garage. The steel cable towed type three-dimensional parking garage comprises a main frame, a vertical lifting transmission device arranged on the main frame, and a horizontal moving system arranged outside the main frame, wherein the vertical lifting transmission device is a winch lifting system, steel cables wound on a winch is connected with a vehicle bracket through a steel cable anti-breakage braking and limiting mechanism, and the connecting part between the winch and the steel cables is provided with an anti-tangling mechanism. The steel cable towed type three-dimensional parking garage overcomes the defects of low working efficiency, high fault rate, poor synchronous property and cost waste of three-dimensional parking garages in the prior art, and through the anti-breakage braking mechanism, the anti-tangling mechanism, and an anti-shaking mechanism, improves safety and stability and ensure normal and uniform pay-off and take-up of the steel cables.

Owner:福建三铭科技有限公司

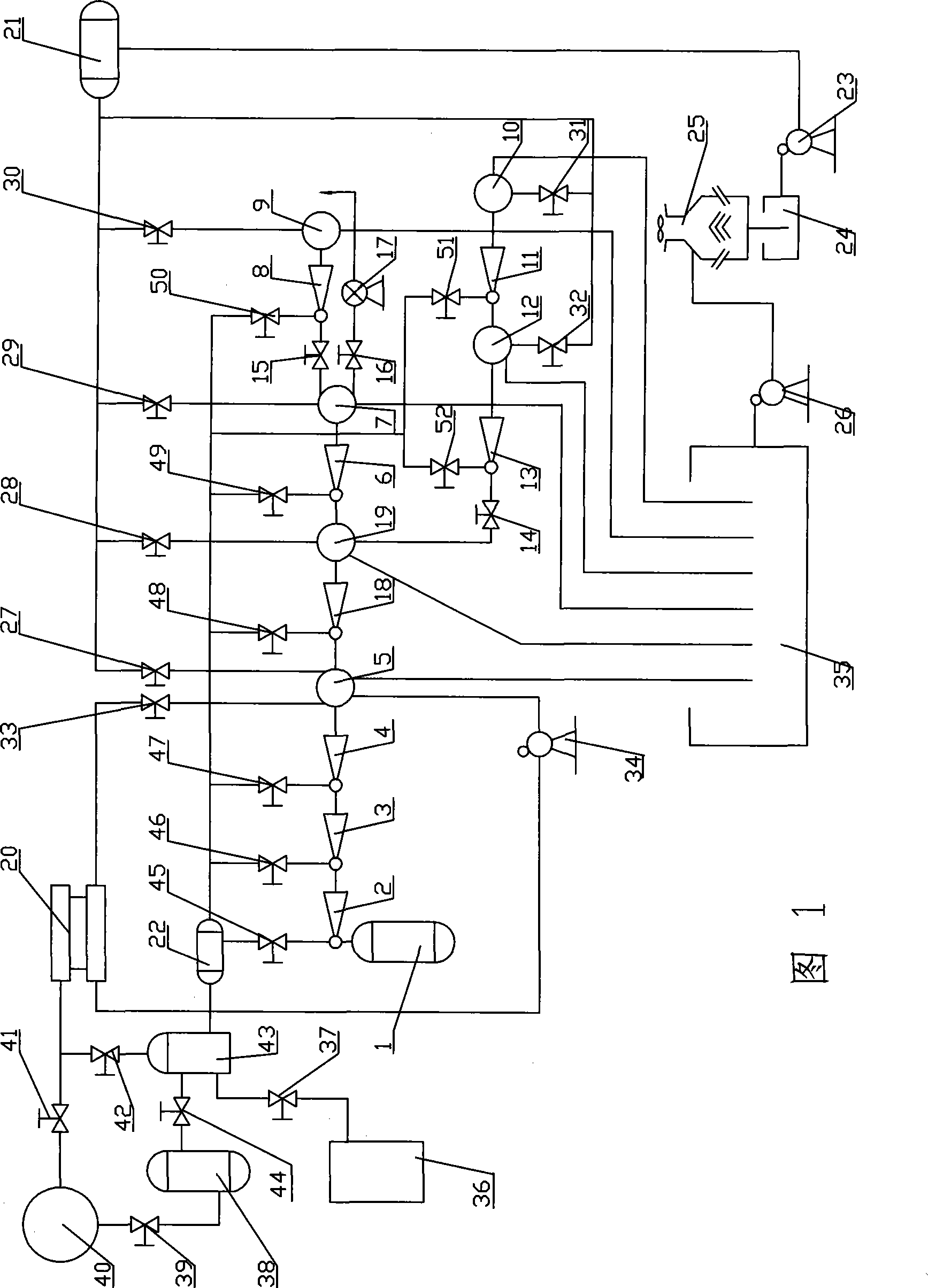

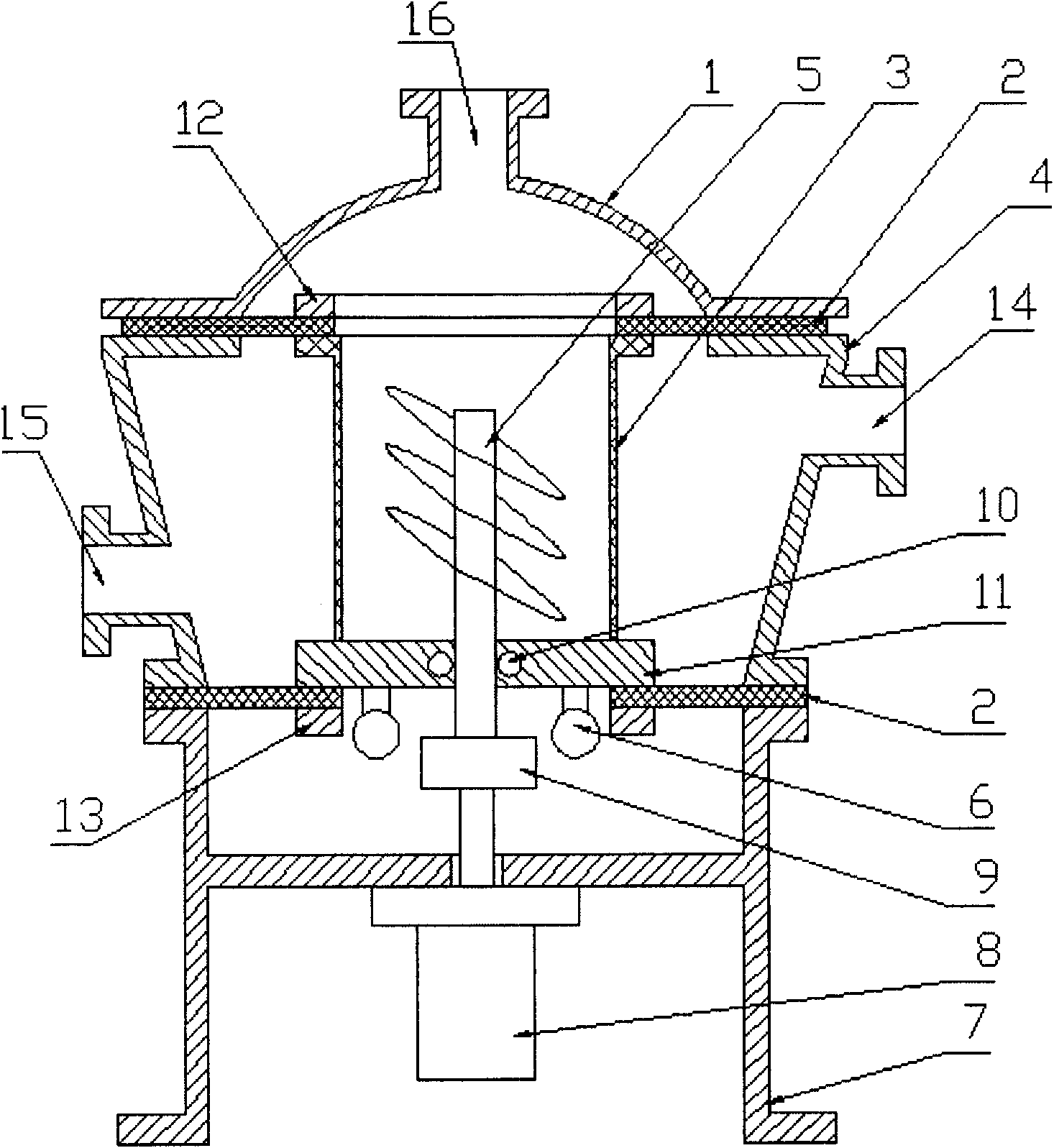

Combined steam jet vacuum pump system capable of utilizing exhaust heat

ActiveCN101457774AGuaranteed long-term reliabilityGuaranteed long-term stabilityJet pumpsMachines/enginesEngineeringRefrigeration

The invention relates to a combined steam injection vacuum pump system capable of utilizing waste heat which is used in a production technique of industrial production needing to obtain vacuum and refining products in vacuum. The combined steam injection vacuum pump unit is mainly formed by the existing steam injection vacuum pump set, especially by additionally arranging a jet apparatus and a condenser between a condenser 5 which is behind the first, the second, the third, the fourth or the fifth grade jet apparatus of the steam injection vacuum pump unit and a jet apparatus and a condenser set which are behind the condenser 5, connecting a water ring type vacuum pump in parallel with the condenser in front of one jet apparatus to from a novel steam injection vaccum pump set and arranging a suction type refrigeration apparatus, a water dividing packet, a steam dividing packet and a waste heat source device on the novel steam injection vacuum pump set. The combined steam injection vacuum pump system capable of utilizing waste heat integrates all the advantages of the existing steam injection vacuum pump and overcomes potential defects thereof by the comprehensive design and not only achieves the effects of energy saving and exhaustion reducing, but also ensures the long period reliability and stability needed by large industrial production.

Owner:陕西向阳真空工程有限公司

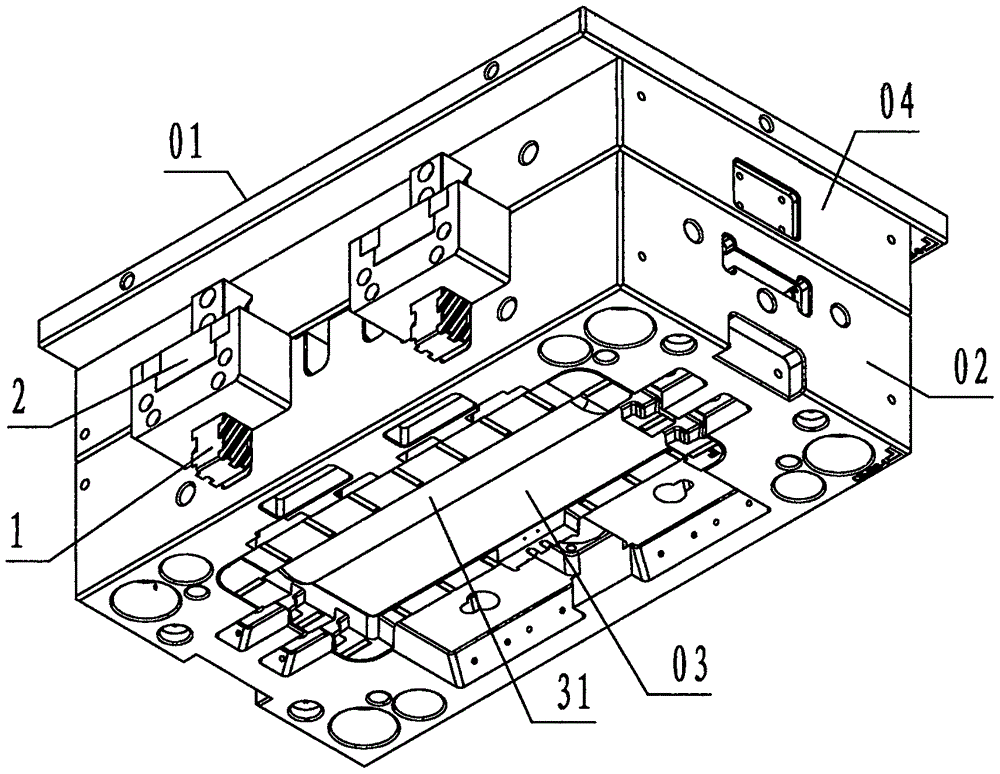

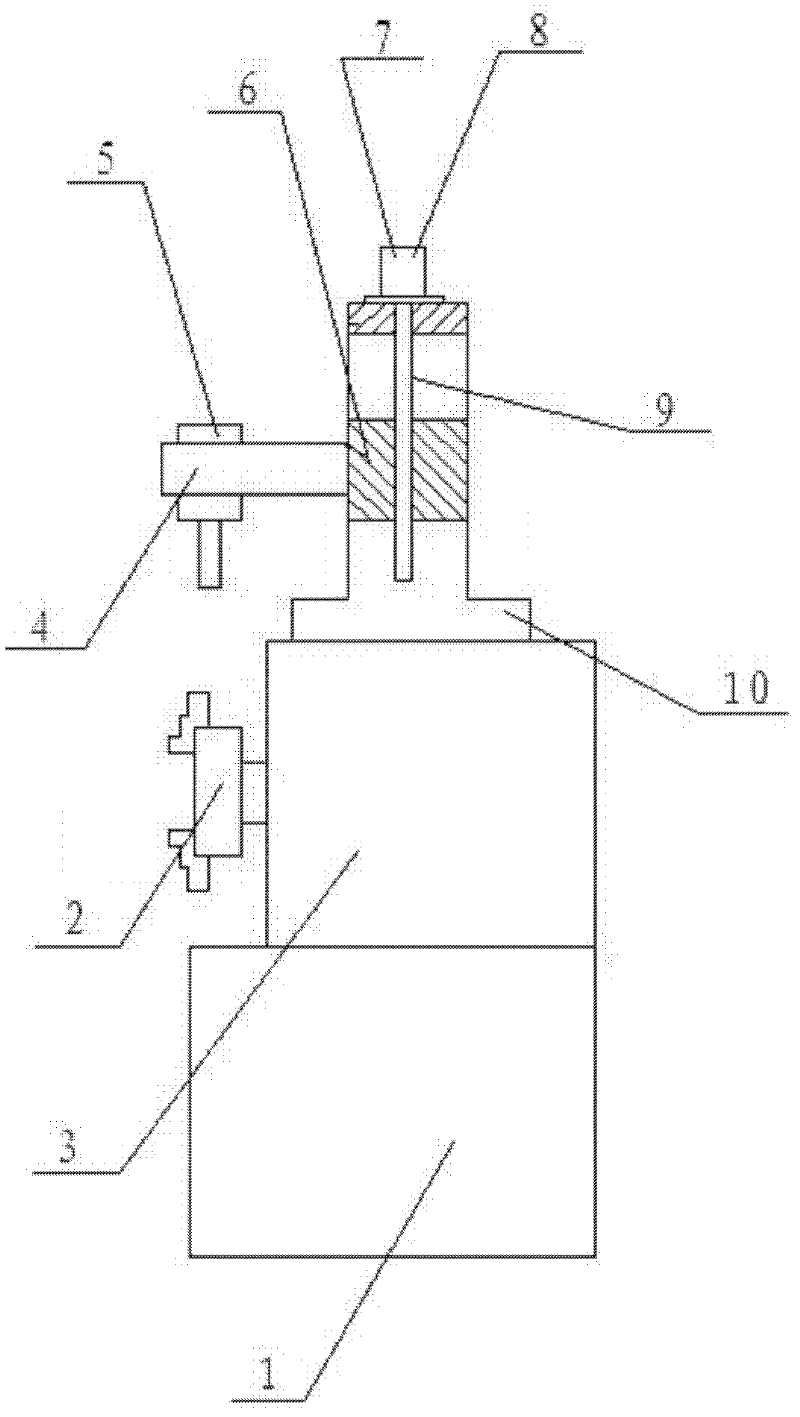

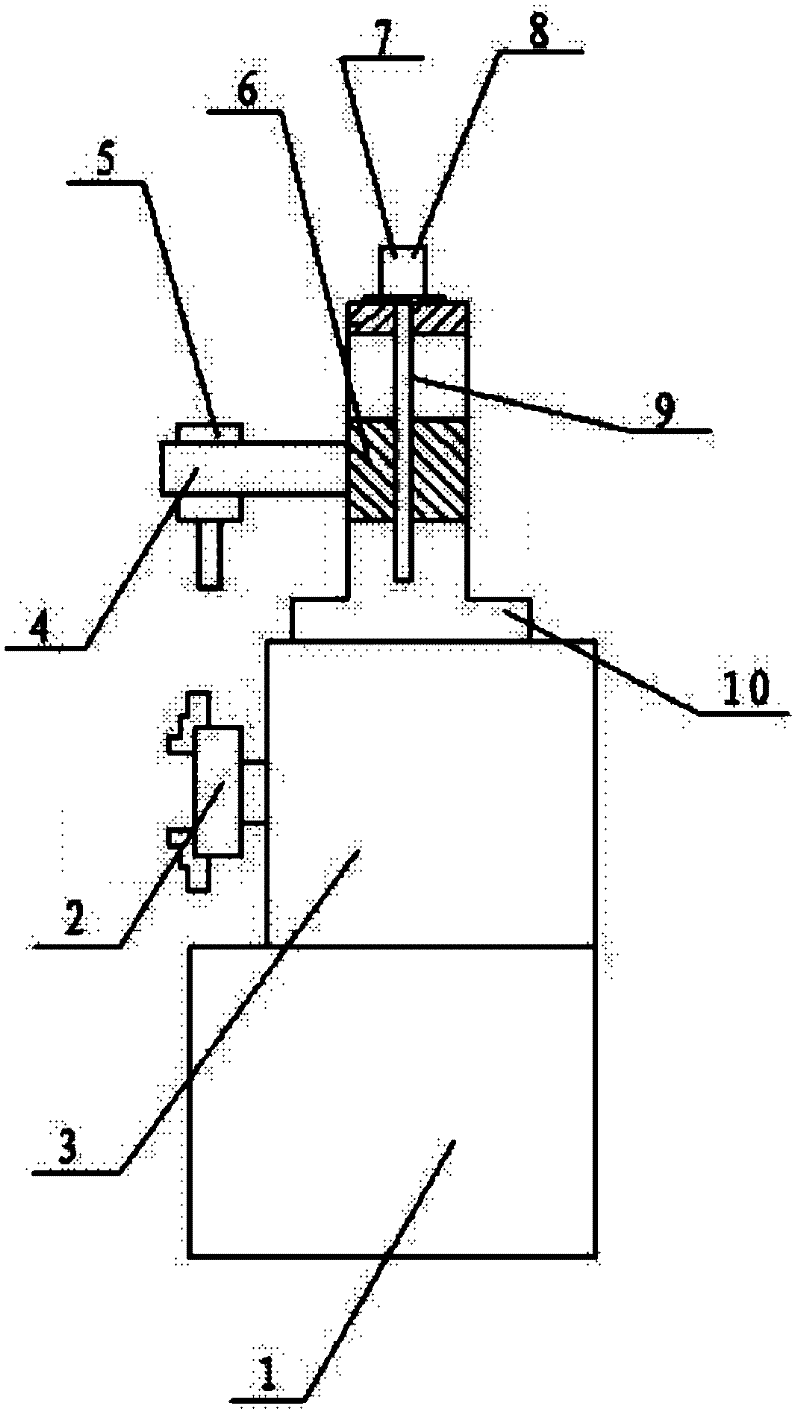

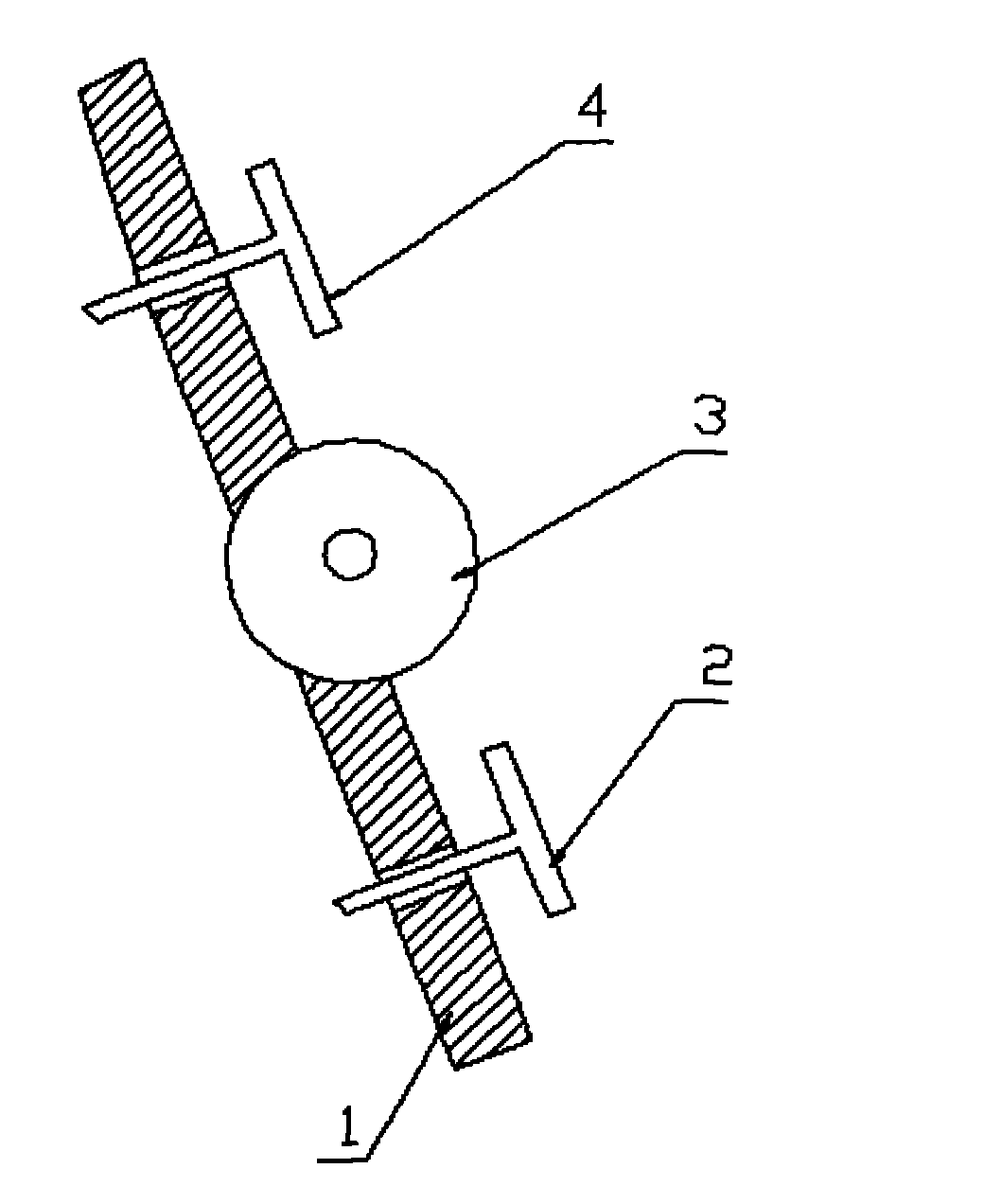

Rack-driven rotational core pulling device at cover half position of injection mold

The invention discloses a rack-driven rotational core pulling device at the cover half position of an injection mold. The rack-driven rotational core pulling device comprises a longitudinal rack (1), a transverse rack (2) and a circular arc gear (3). According to the adopted technical scheme, the longitudinal rack is located on the outer side face of a cover half carrier plate in the up-down direction, the upper end of the longitudinal rack is fixedly connected with the outer side face of the cover half carrier plate, the transverse rack is located in a sliding groove formed in a cavity plate in the left-right direction, the circular arc gear is rotationally located in the cavity plate, the longitudinal rack is engaged with the transverse rack, the transverse rack is engaged with the circular arc gear, and the circular arc gear is connected with an inverted buckle core pulling block; and when the rack-driven rotational core pulling device works, the longitudinal rack drives the transverse rack to be pulled out leftwards, the transverse rack drives the circular arc gear and the inverted buckle core pulling block to rotate in the anticlockwise direction, and the inverted buckle core pulling block is rotated to complete core pulling from an outer inverted buckle. By means of mechanical drive, injection mold outer inverted buckle core pulling achieves the purposes that faults are reduced and the cost is reduced.

Owner:NINGBO YUEFEI MOLD

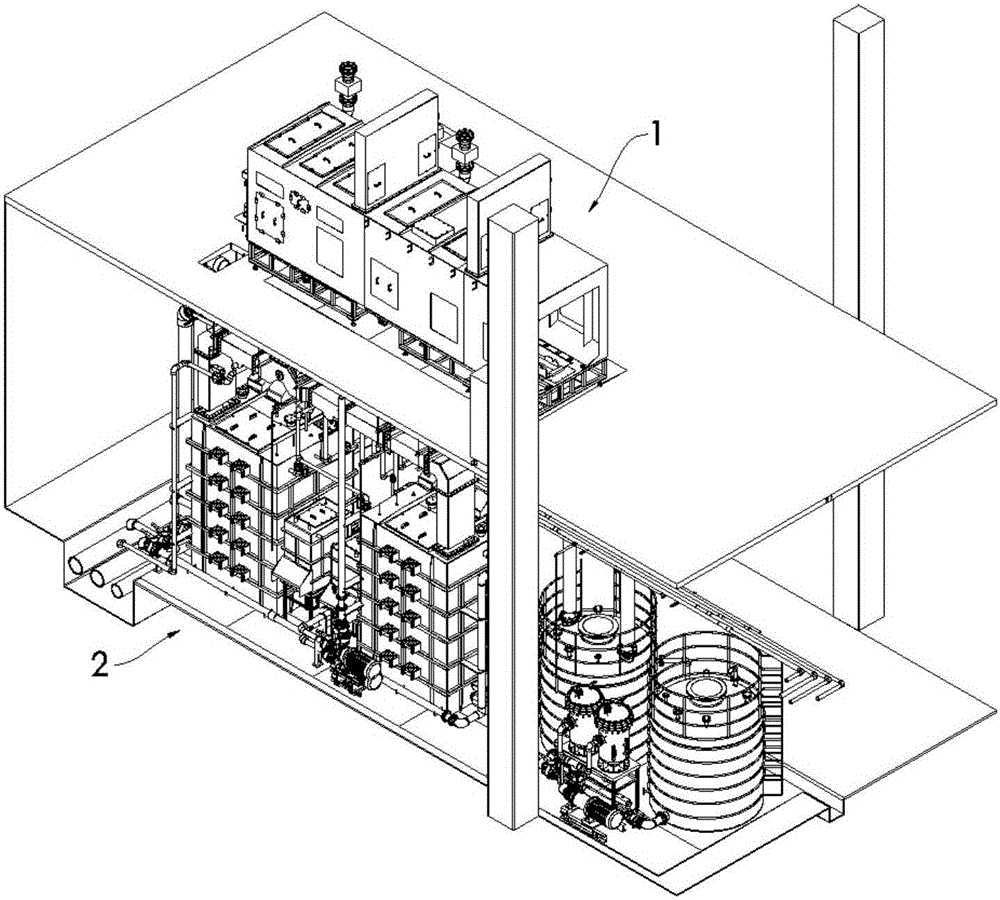

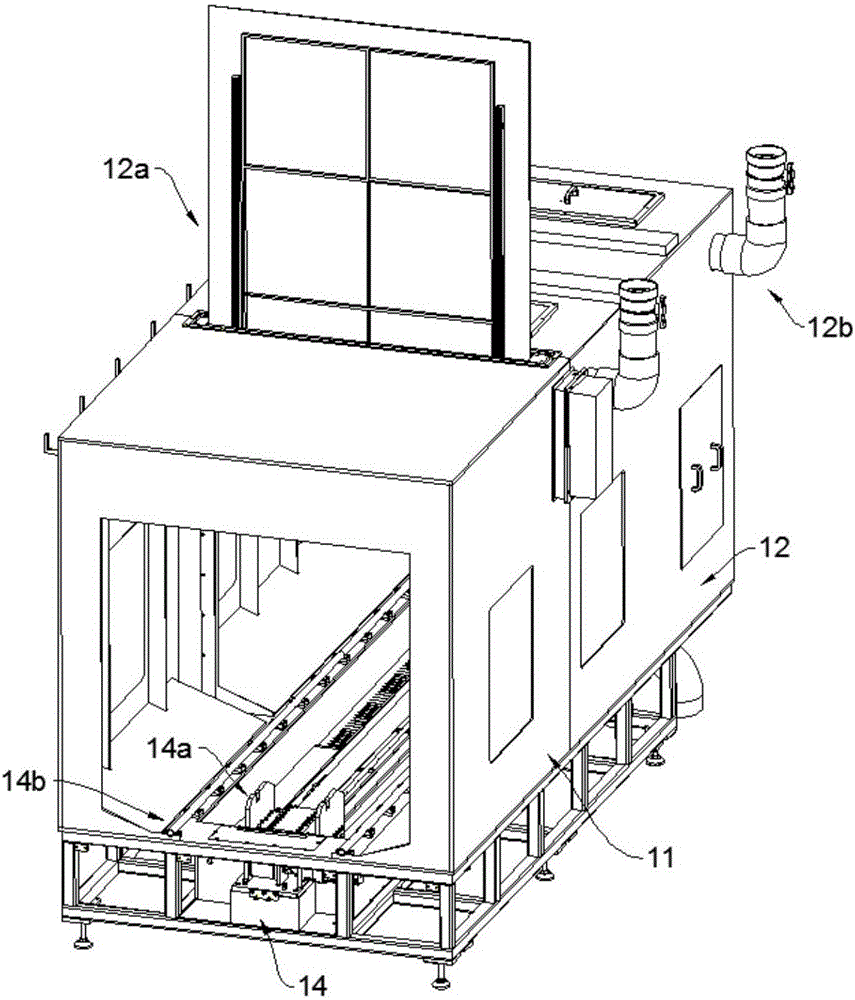

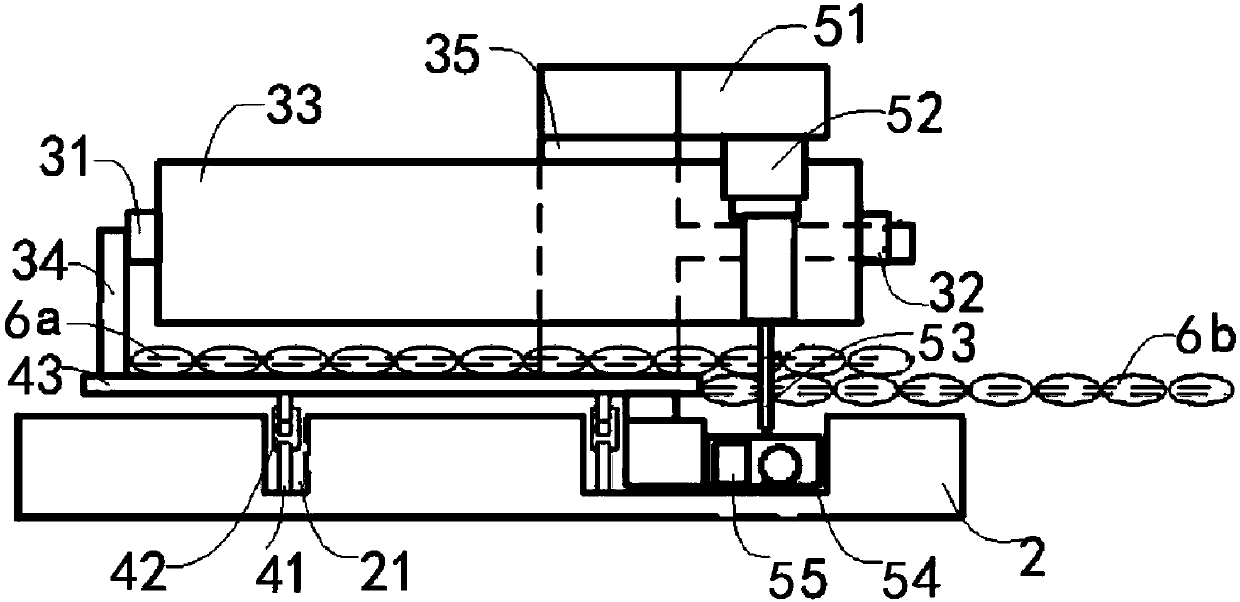

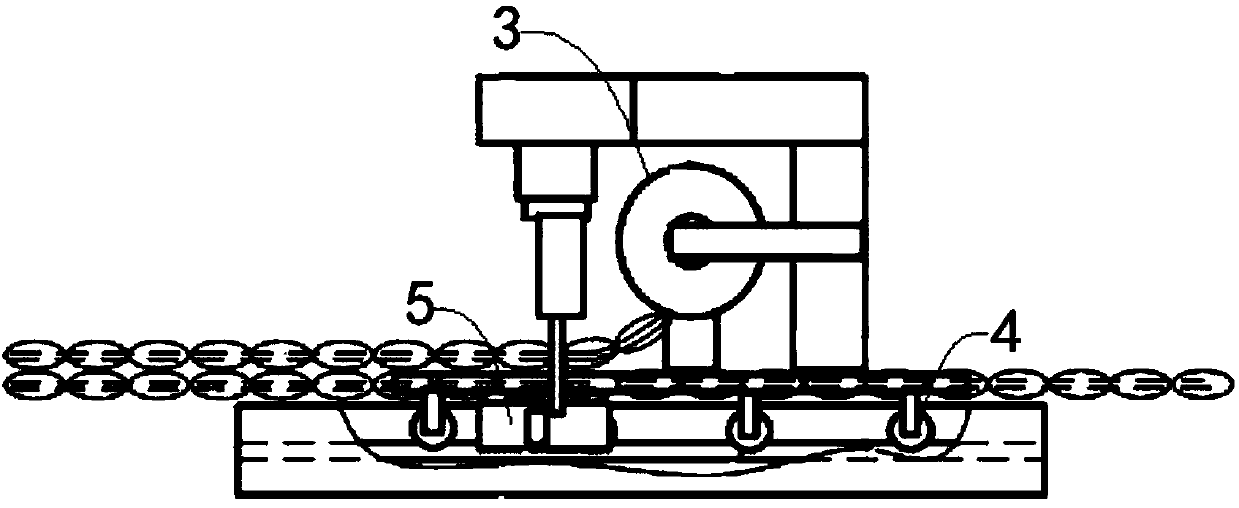

Top-jet type spray etching machine

A top-jet type spray etching machine comprises an etching machine body and a liquid medicine circulating system, wherein the etching machine body is mainly composed of a transition area, a cleaning area and an etching area, spraying devices are arranged on the cleaning area and the etching area respectively, synchronous belt conveying devices are arranged below the transition area and the cleaning area, a servo drive motor is arranged below the transition area, a slide rail penetrating through the transition area, the cleaning area and the etching area is arranged below the etching machine body, etching basket tools are placed on the slide rail, the synchronous belt conveying devices are connected and linked through push rods, and the liquid medicine circulating system is mainly composed of a DI water tank body, a chemical liquid medicine tank body, a heating tank, corresponding pipelines, corresponding valves and a circulating pump. In the glass panel etching process, the temperature, pressure, flow and the like of liquid medicine can be controlled in a full-automatic mode, double-sided waterfall etching is conducted on glass panel, no manual operation is needed in the whole working process, cleaning and etching are both completed automatically, and the etching precision and efficiency are remarkably improved.

Owner:CHENGDU IND INVESTMENT ELECTRONICS EQUIP

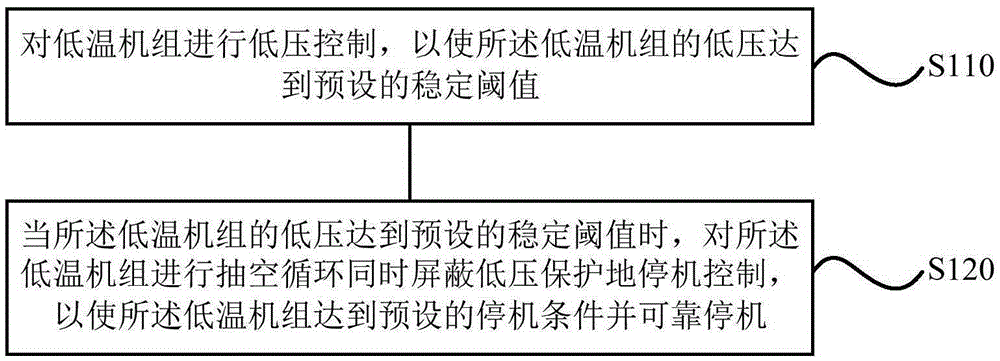

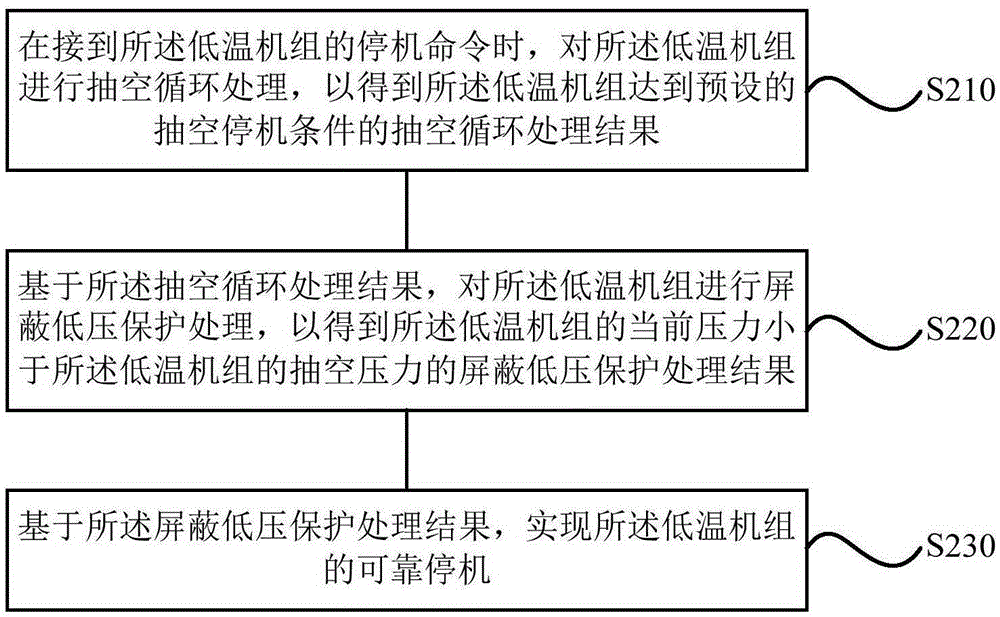

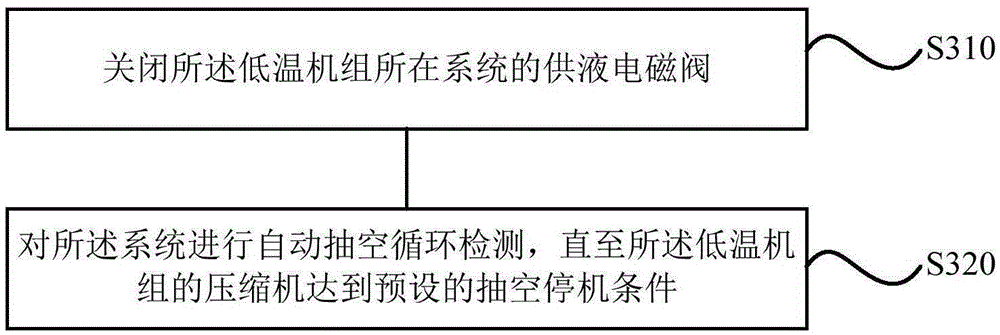

Stopping method and system for low temperature unit, low temperature unit and refrigerating system

ActiveCN105241144ASolve the problem of low voltage protectionImprove operational safetyRefrigeration safety arrangementFailure rateEngineering

The invention discloses a stopping method and system for a low temperature unit, the low temperature unit and a refrigerating system. The stopping method for the low temperature unit comprises the steps of carrying out low pressure control over the low temperature unit to enable the low pressure of the low temperature unit to reach the preset stable threshold value; carrying out pumping-out circulation on the low temperature unit when the low pressure of the low temperature unit reaches the preset stable threshold value, and carrying out low pressure protection shielding to achieve stopping control and to enable the low temperature unit to meet the preset stopping condition and reliably stop when pumping-out circulation is carried out on the low temperature unit. According to the scheme, the shortcomings that the pressure control accuracy is low, the system operation safety is poor and the abnormal failure rate is high in the prior art can be overcome, and the stopping method and system have the advantages that the pressure control accuracy is high, the system operation safety is high and the abnormal failure rate is low.

Owner:GREE ELECTRIC APPLIANCES INC

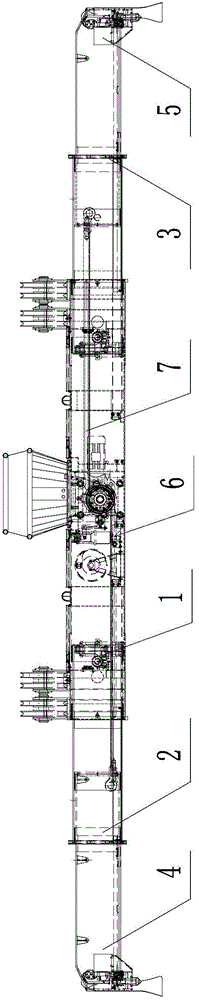

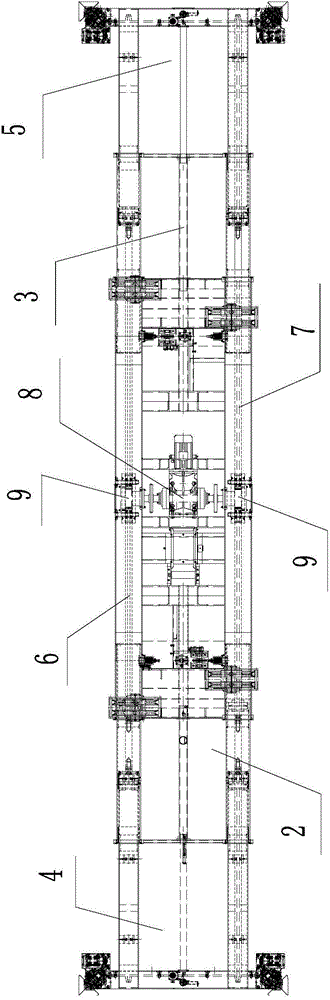

Telescopic mechanism of pinion-and-rack container spreader

ActiveCN104692229AReasonable designEasy maintenanceLoad-engaging elementsFriction gearingsEngineeringReducer

The invention relates to a telescopic mechanism of a pinion-and-rack container spreader. The telescopic mechanism comprises a main beam, a front middle beam, a rear middle beam, a front end beam and a rear end beam, wherein the front middle beam is arranged at the front end of the main beam, the rear end of the front middle beam is connected with the main beam by plugging and in telescopic fit with the front end of the main beam, the front end beam is arranged at the front end of the front middle beam and in telescopic fit with the front middle beam; the rear middle beam is arranged at the rear end of the main beam, and the front end of the rear middle beam is connected with the mean beam by plugging and in telescopic fit with the rear end of the main beam; the rear end beam is arranged at the rear end of the rear middle beam and in telescopic fit with the rear middle beam; and the maim beam is provided with a motor and a motor reducer, and a gear and rack drive mechanism is arranged between the motor reducer and the end beam. The gear and rack drive mechanism is reasonable in design, and convenient to maintain. The defects such as oil leak, high failure rate, complex and difficult maintenance and the like of hydraulic telescopic container spreaders are overcome.

Owner:张家港市盛达冶金吊具制造有限公司

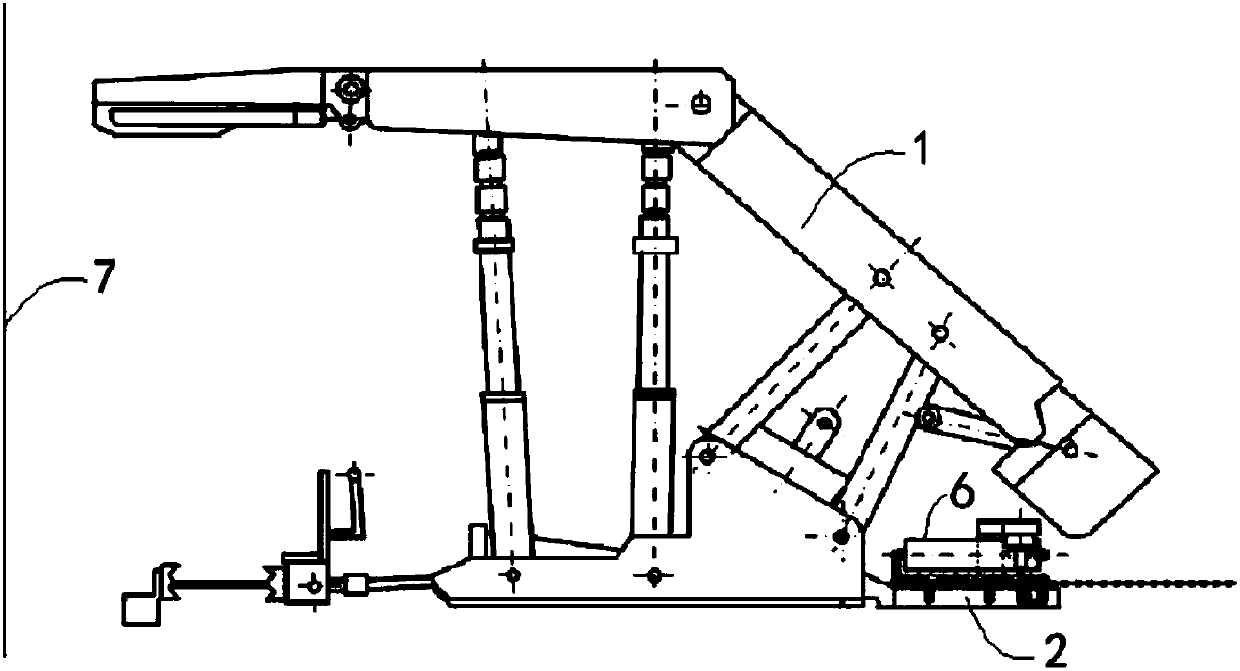

Bottom plate automatic net spreading and connecting device and method for slicing of thick seams

The invention discloses a bottom plate automatic net spreading and connecting device and method for slicing of thick seams. The bottom plate automatic net spreading and connecting device comprises a plurality of hydraulic supports which are in parallel with an excavation working face, and the tail of each hydraulic support is provided with a rear seat. A net coil spreading mechanism, a slipping mechanism and a net connecting mechanism are arranged on each rear seat. The net coil spreading mechanisms are used for mounting or spreading well wound net coils. The slipping mechanisms are arranged below the net coil spreading mechanisms and used for driving the net coil spreading mechanisms to slip in the mode of being parallel with the excavation working face to spread the net coils. The net connecting mechanisms are fixed to the slipping mechanisms and used for sewing and connecting the overlapped parts of the to-be-spread net coils and the spread net coils. The automatic net connecting function is achieved, the number of equipment is decreased, the equipment cost is reduced, and meanwhile the bottom plate automatic net spreading and connecting device and method further have the advantages that the net spreading efficiency is high, the workload of downhole workers is little, and operability and practicability are greatly achieved.

Owner:SHANDONG UNIV OF SCI & TECH

Novel friction clutch for walking tractor

The invention relates to a novel friction clutch for a walking tractor, which is characterized in that the conical disc type friction clutch has a stationary fitted inclined surface; the stationary fitted inclined surface is installed on a transmission shaft on one side of a gear case; a rotatable fitted inclined surface and the stationary fitted inclined surface are oppositely installed on the transmission shaft; an operating lever is connected with the rotatable fitted inclined surface; a fly wheel is installed on the transmission shaft on the outer side of the rotatable fitted inclined surface through a bearing; a formed inner conical surface is formed on the outer side of the fly wheel; a drive disc is a conical body, the conical degree of the drive disc is the same as that of the inner conical surface at the inner side of the fly wheel, and the drive disc is installed on the transmission shaft on the outer side of the fly wheel through a spline; and a compression spring is installed on the transmission shaft on the outer side of the drive disc by a nut.

Owner:朱友刚

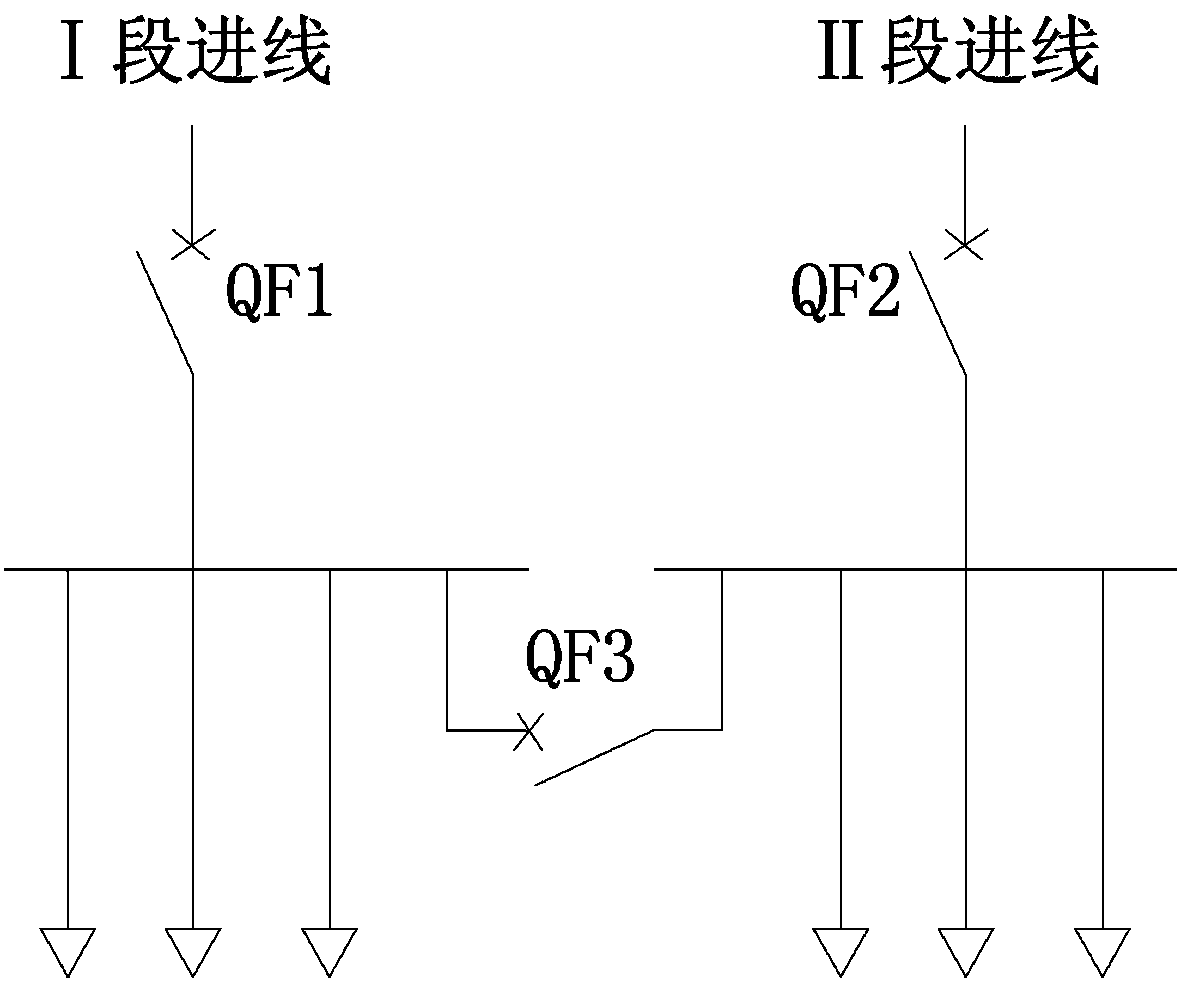

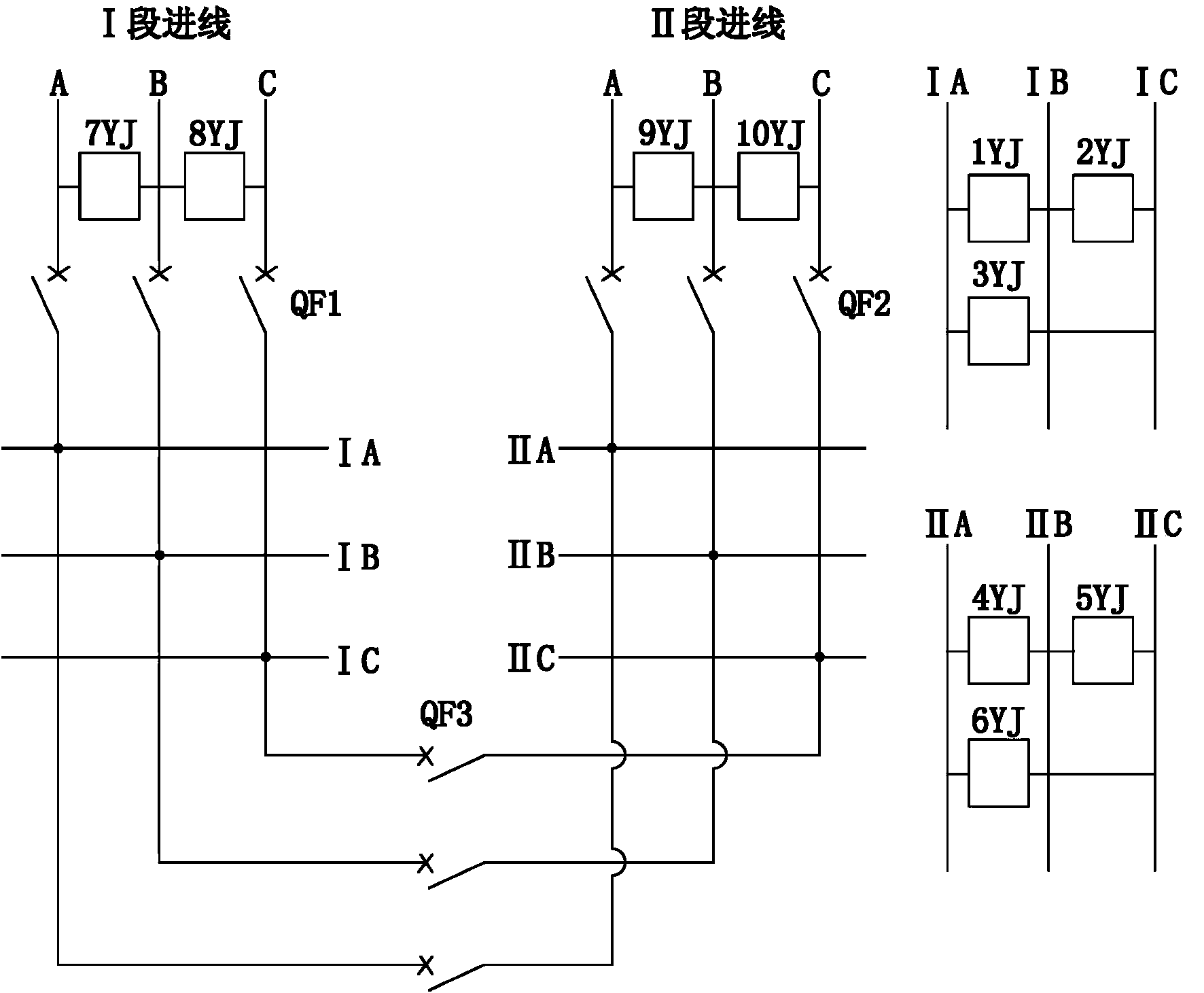

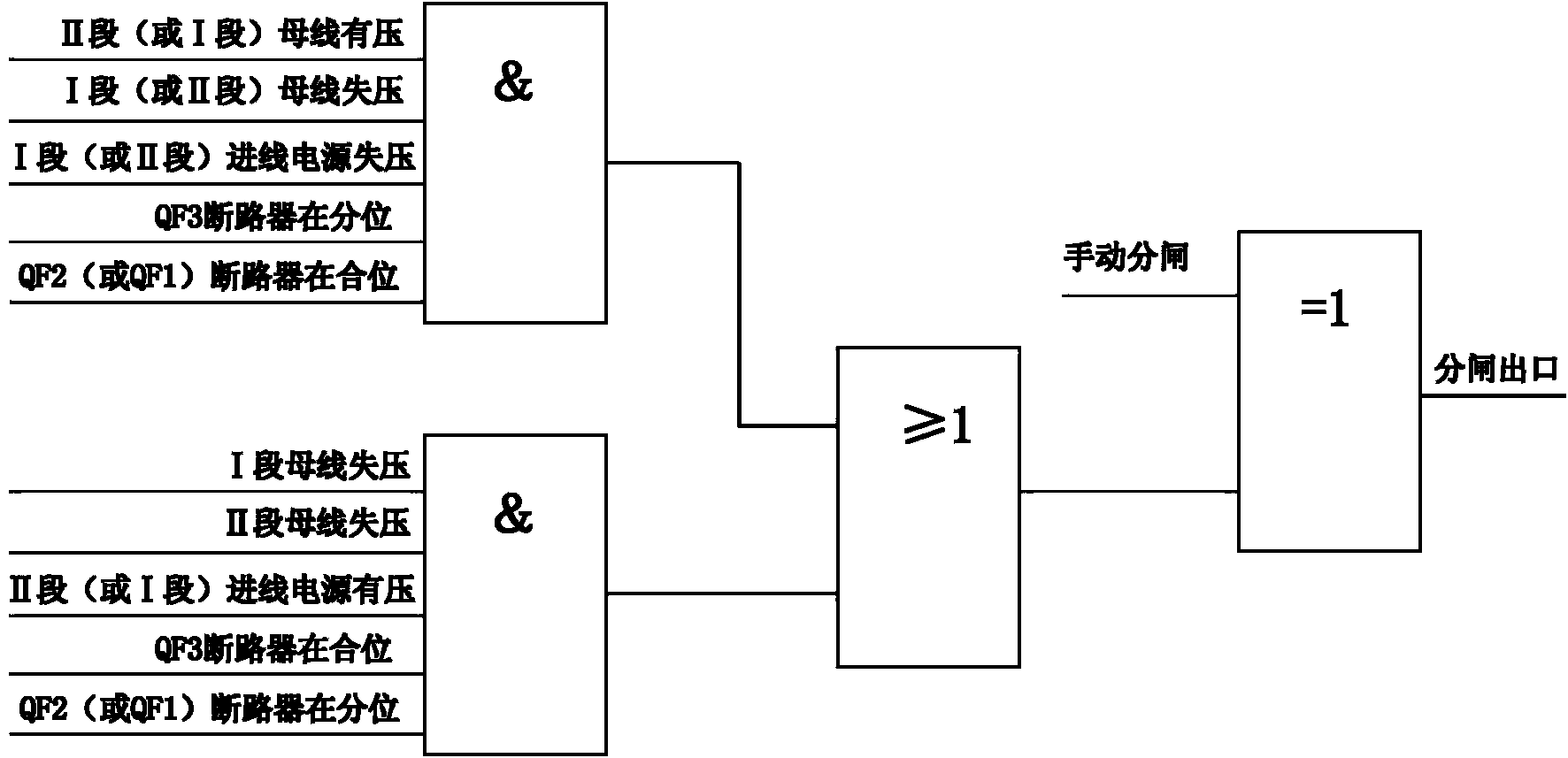

Power supply standby device for transformer substation achieved based on PLC

InactiveCN103887873AAchieve operational controlSafe and stable operationPower network operation systems integrationInformation technology support systemTransformerEngineering

The invention discloses a power supply standby device for a transformer substation achieved based on a PLC. The power supply standby device for the transformer substation achieved based on the PLC comprises the PLC, a bus detection circuit, an incoming line power supply detection circuit, a breaker control circuit, a breaker position signal acquisition circuit, a breaker control intermediate relay circuit, a breaker on-off indicating circuit, a standby action reset circuit and a breaker circuit, wherein the bus detection circuit, the incoming line power supply detection circuit, the breaker control circuit, the breaker position signal acquisition circuit, the breaker control intermediate relay circuit, the breaker on-off indicating circuit and the standby action reset circuit are respectively connected with the PLC, and the breaker circuit is connected with the breaker control intermediate relay circuit. The power supply standby device for the transformer substation achieved based on the PLC can overcome the defects that the fault rate is high, reliability is low and safety is poor in the prior art, and can achieve the advantages of being low in fault rate, high in reliability and good in safety.

Owner:STATE GRID CORP OF CHINA +2

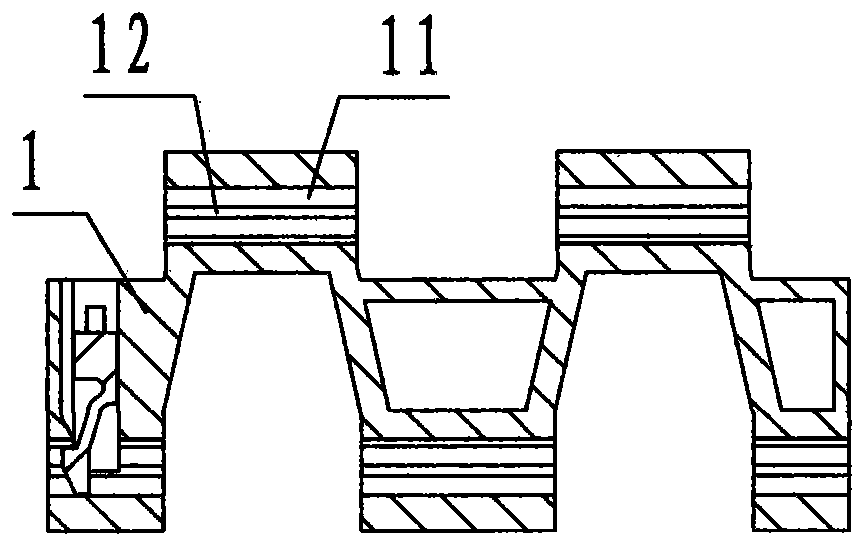

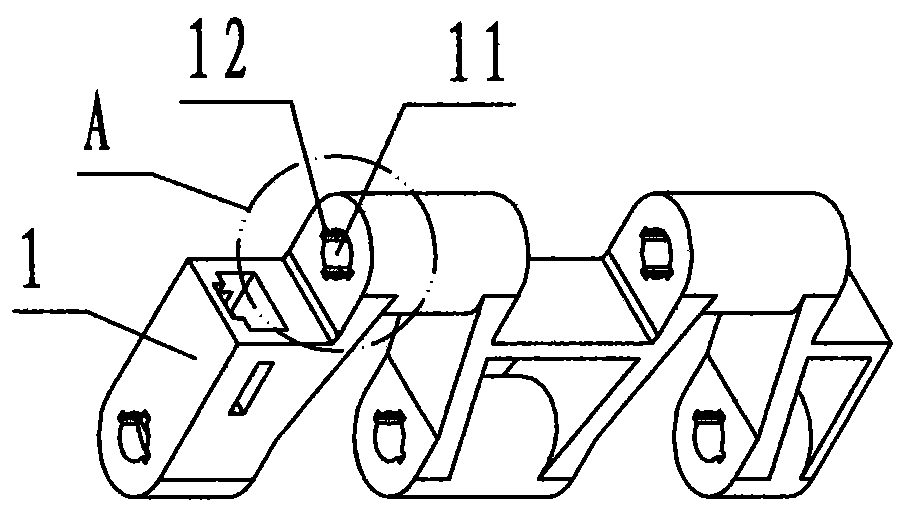

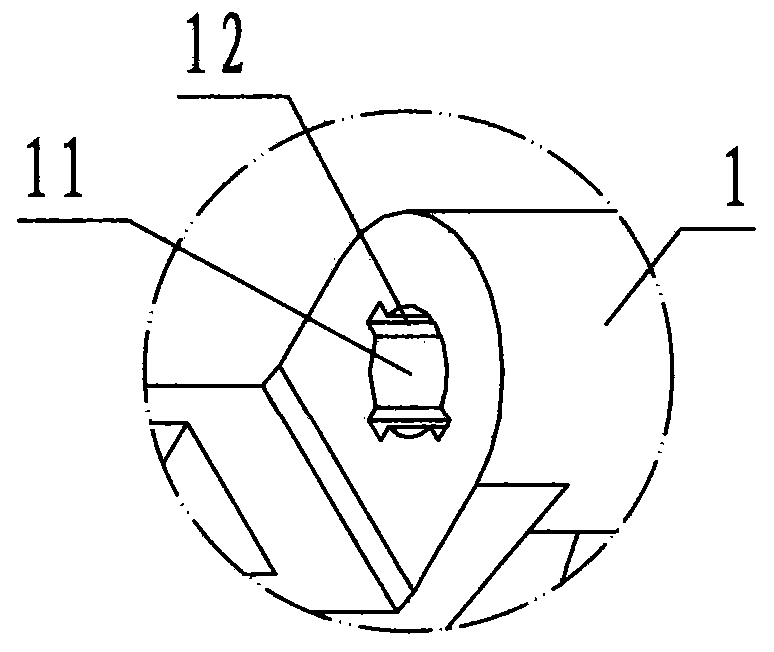

Plastic module chain assembly provided with dirt discharge groove

ActiveCN104196962AReduce wearExtended service lifeConveyorsShacklesFailure ratePetroleum engineering

The invention discloses a plastic module chain assembly provided with a dirt discharge groove. The plastic module chain assembly provided with the dirt discharge groove comprises a D module chain (1) and a Z module chain (2). The plastic module chain assembly composed of the D module chain and the Z module chain is adopted, a D dirt discharge groove is formed in a D shaft pin hole of the D module chain, and a Z dirt discharge groove is formed in a Z shaft pin hole of the Z module chain. The D module chain and the Z module chain form a chain-belt-typed conveying belt in a spliced mode, and then the D dirt discharge groove and the Z dirt discharge groove are communicated in series. When working is conducted, oil dirt generated, when the conveying belt runs, in the D shaft pin hole and the Z shaft pin hole is discharged timely through the D dirt discharge groove and the Z dirt discharge groove which are communicated in series, wear of the oil dirt to the shaft pin holes is reduced, service life of the plastic module chain assembly is prolonged, and the purposes of lowering abrasion, reducing the failure rate, reducing maintenance cost and improving operation efficiency of the plastic chain-belt-typed conveying belt are achieved.

Owner:NINGBO DETONG ELECTRONICS PLASTIC

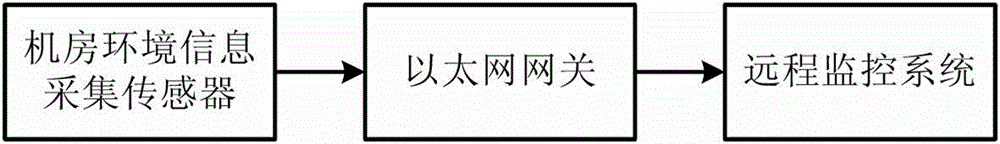

Equipment room environment control system

InactiveCN103984303ARealize scientific managementRealize unified and centralized monitoring and managementTotal factory controlProgramme total factory controlFailure rateControl system

The invention discloses an equipment room environment control system. The equipment room environment control system mainly comprises an equipment room environment information acquisition sensor, an Ethernet gateway and a remote monitoring system, wherein the equipment room environment information acquisition sensor, the Ethernet gateway and the remote monitoring system are connected in sequence, the equipment room environment information acquisition sensor is used for collecting the environment information of an equipment room to be measured and transmits the collected environment information to the remote monitoring system through the Ethernet gateway, the Ethernet gateway is used for providing a data transmission channel between the equipment room environment information acquisition sensor and the remote monitoring system, the remote monitoring system is used for remotely monitoring the environment of the equipment room based on the information collected by the equipment room environment information acquisition sensor. The equipment room environment control system can overcome the defects that in the prior art, the energy consumption is high, the failure rate is high, and the environmental friendliness is poor and has the advantages that the energy consumption is low, the failure rate is low, and the environmental friendliness is good.

Owner:JIANGSU LINK SENSOR TECH

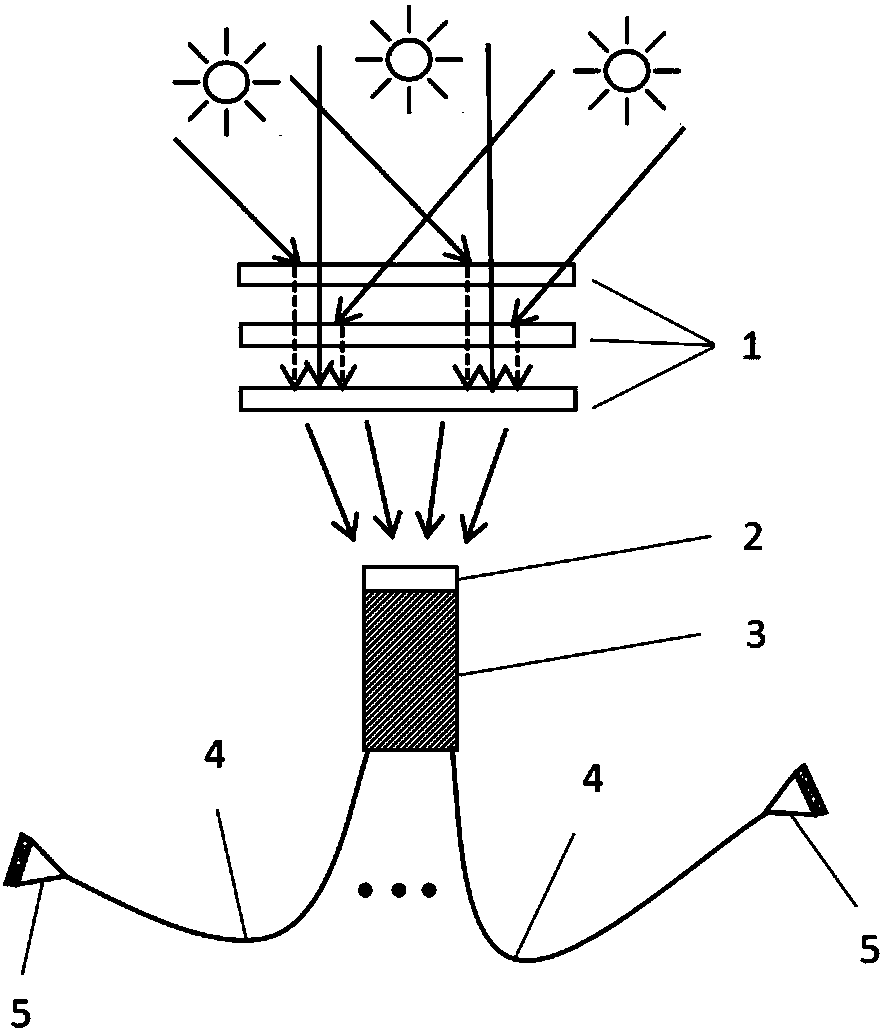

Sunlight holographic non-tracking focus illumination system

InactiveCN108278568AIncrease profitLarge working angleMechanical apparatusLight guides detailsLighting systemSolar battery

The invention provides a sunlight holographic non-tracking focus illumination system. The system comprises a multi-layer holographic optical collector, an optical energy receiver, an optical fiber endsleeve head, an optical fiber and a scattering illuminator; each layer of the multi-layer holographic optical collector generates diffraction to incident light at a certain angle only; a large-anglenon-tracking light collection effect is achieved by virtue of multi-layer in-series superposition; the optical energy receiver is placed at a light focusing position of the multi-layer holographic optical collector and is connected with the optical fiber end sleeve head and the optical fiber; the optical fiber end sleeve head is used for restraining a multi-core optical fiber within the range of the optical energy receiver; the multi-core optical fiber can be used for transmitting optical energy and dividing the light into a plurality of beams so as to realize multi-user illumination; and thescattering illuminator is connected with the tail end of the optical fiber and is used for scattering the optical energy inside the optical fiber to form indoor illuminating light which is transmittedin all directions and also counteracting a part of chromatic dispersion influences of the holographic optical collector and the optical fiber. According to the sunlight holographic non-tracking focusillumination system provided by the invention, sunlight is focused and directly brought in a room for illumination, thus the problems about low solar battery efficiency, high cost and pollution existing in the photovoltaic conversion technology are prevented, so the sunlight holographic non-tracking focus illumination system is environmentally friendly, safe and reliable.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Electronic non-contact bidirectional rotary intelligent wiper motor

InactiveCN103427567AIncrease effective output powerLow costStructural associationMechanical energy handlingFailure rateElectric equipment

The invention relates to an electronic non-contact bidirectional rotary intelligent wiper motor (called NIM for short) based on a current international and domestic universal mechanical contact motor. The wiper motor overcomes the shortcomings that the mechanical contact motor is cumbersome in structure, short in service life, high in failure rate, unstable in quality, difficult to mount and the like for a long time, interferential radiation cannot be generated when the wiper motor runs, other electronic devices in an automobile are protected from interference, and a structure of a transmission assembly in a wiper assembly is particularly omitted, so that the wiper assembly is simpler in structure and lower in use cost. The wiper motor fills up international and domestic gaps of the field of an automobile wiper motor industry.

Owner:张岳峰 +2

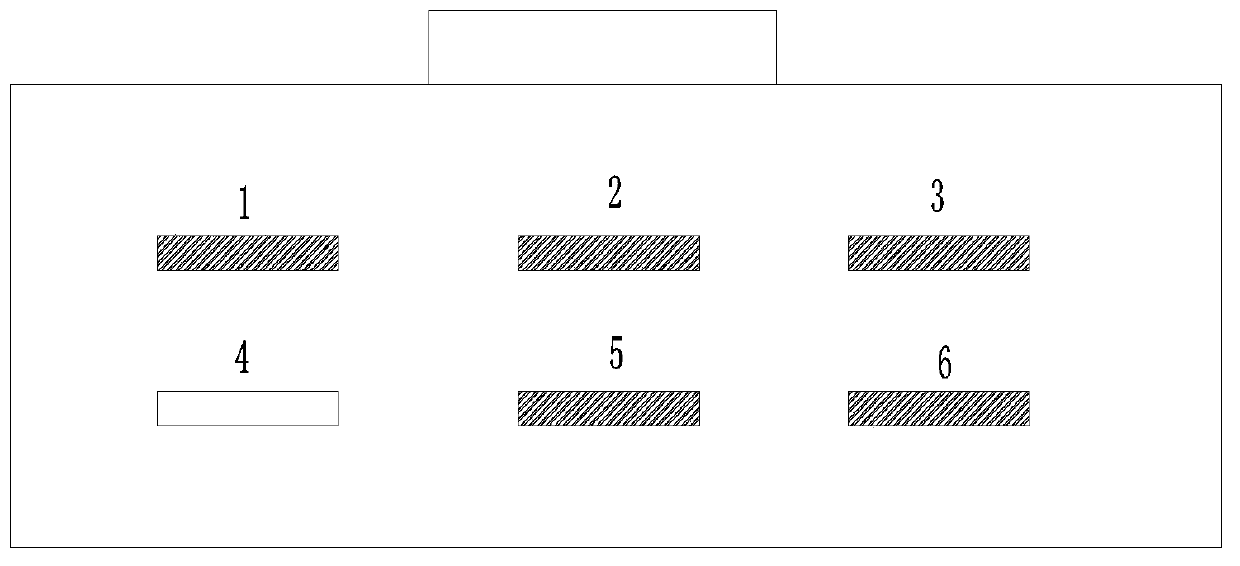

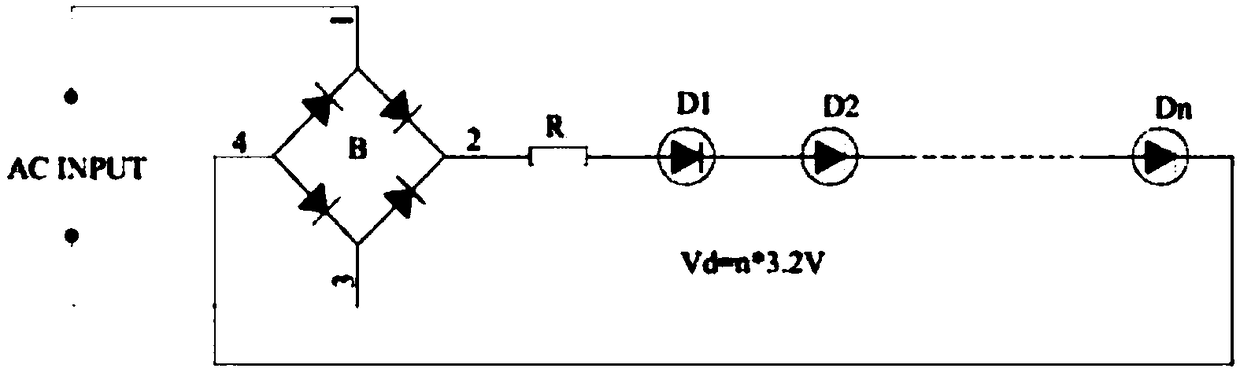

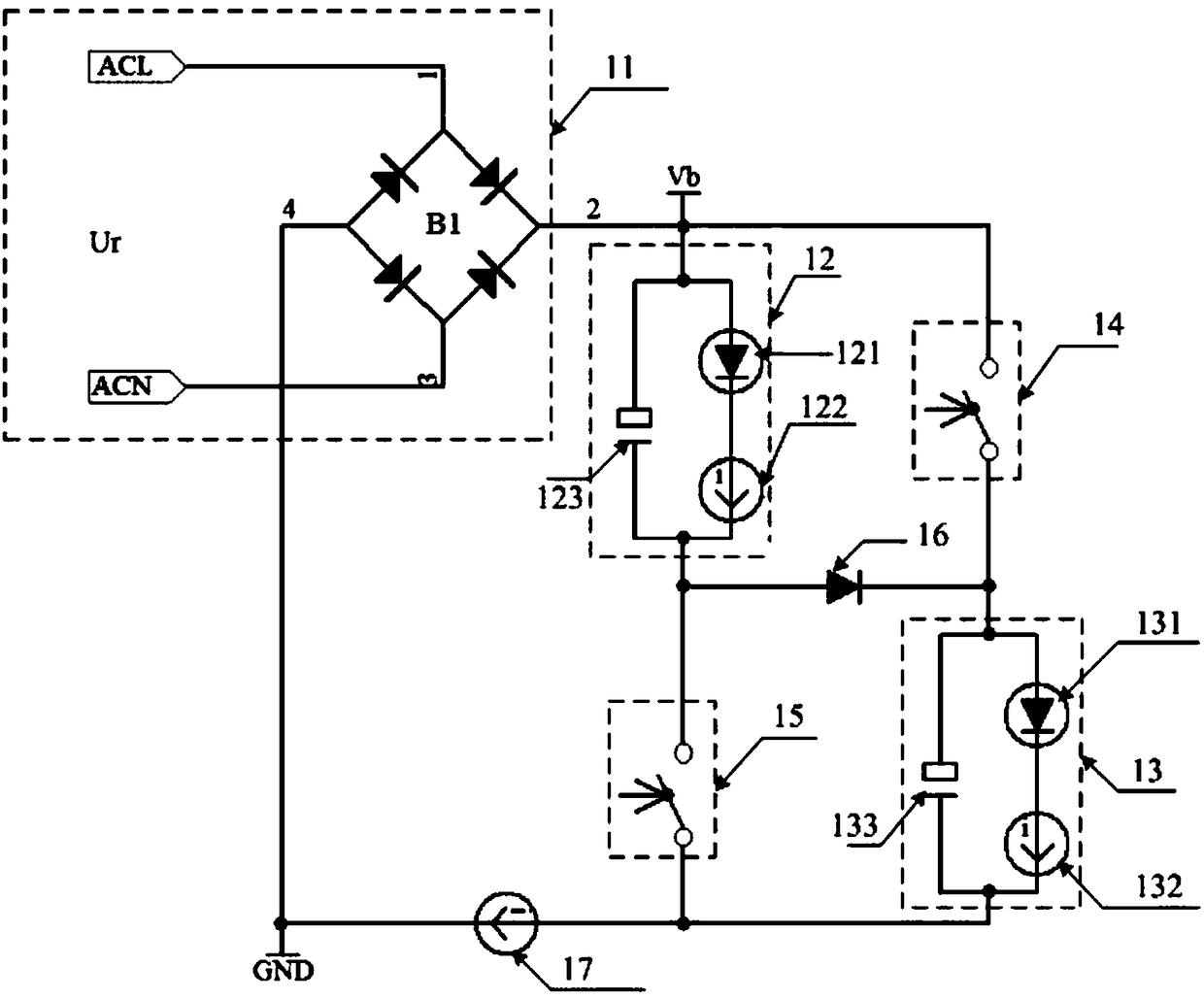

Self-adaption LED lamp

ActiveCN108156713AOvercome the failure rateOvercoming distractionsElectrical apparatusElectroluminescent light sourcesCapacitancePower flow

The invention discloses a self-adaption LED lamp. The lamp comprises a direct current power supply, a first LED component, a second LED component, a first current control switch, a second current control switch, a first polar tube and a second polar tube. The first LED component comprises a first LED lamp, a first constant current circuit and a first electrolytic capacitor; the second LED component comprises a second LED lamp, a second constant current circuit and a second electrolytic capacitor; an input end of the first LED component is respectively connected with a positive input end of thedirect current power supply and one end of the first current control switch, and positive poles of the first polar tube and second polar tube are respectively connected with an output end of the first LED component and one end of the second current control switch; negative poles of the first polar tube and second polar tube are respectively connected with the other end of the first current control switch and an input end of the second LED component, and the other end of the second current control switch is respectively connected with an output end of the second LED component and a negative output end of the direct current power. The LED lamp has the advantages that the luminescene is constantly stable, the stroboflash can not appear, the power factor is high, and the harmonic distortionis small.

Owner:GUANGZHOU PLEMAS LIGHTING CO LTD

Wind-power pest clearing device for pest killing lamp

InactiveCN104886020AEfficient insect removalThoroughly clear insectsInsect catchers and killersPower gridEngineering

A wind-power pest clearing device for a pest killing lamp comprises a wind-power rotary frame and a pest clearing mechanism mounted on the wind-power rotary frame. The wind-power rotary frame arranged on the periphery of the pest killing lamp comprises an upper support, a lower support and a plurality of rocker shafts, and the upper support and the lower support are connected through the rocker shafts. The pest clearing mechanism comprises upper rockers, lower rockers and involute-tooth rods, the upper rockers are rotatably mounted at the upper ends of the rocker shafts respectively, the lower rockers are rotatably mounted at the lower ends of the rocker shafts respectively, two ends of each involute-tooth rod are rotatably mounted at one end of the corresponding upper rocker and one end of the corresponding lower rocker respectively, and a centrifugal weight is fixedly connected to the other end of each of the upper rockers and the lower rockers. Reset springs are mounted at two ends of each rocker shaft and enable the upper rockers, the lower rockers, the centrifugal weights and the involute-tooth rods in non-operating states to be isolated from an electrified net of the pest killing lamp. The wind-power pest clearing device for the pest killing lamp is simple in structure, and high efficiency in pest clearing can be realized. Due to the fact that the pest clearing device is driven by wind power, consumption of electric energy is avoided, and economy and environment friendliness are realized.

Owner:ANHUI TUODIAN LIGHTING TECH

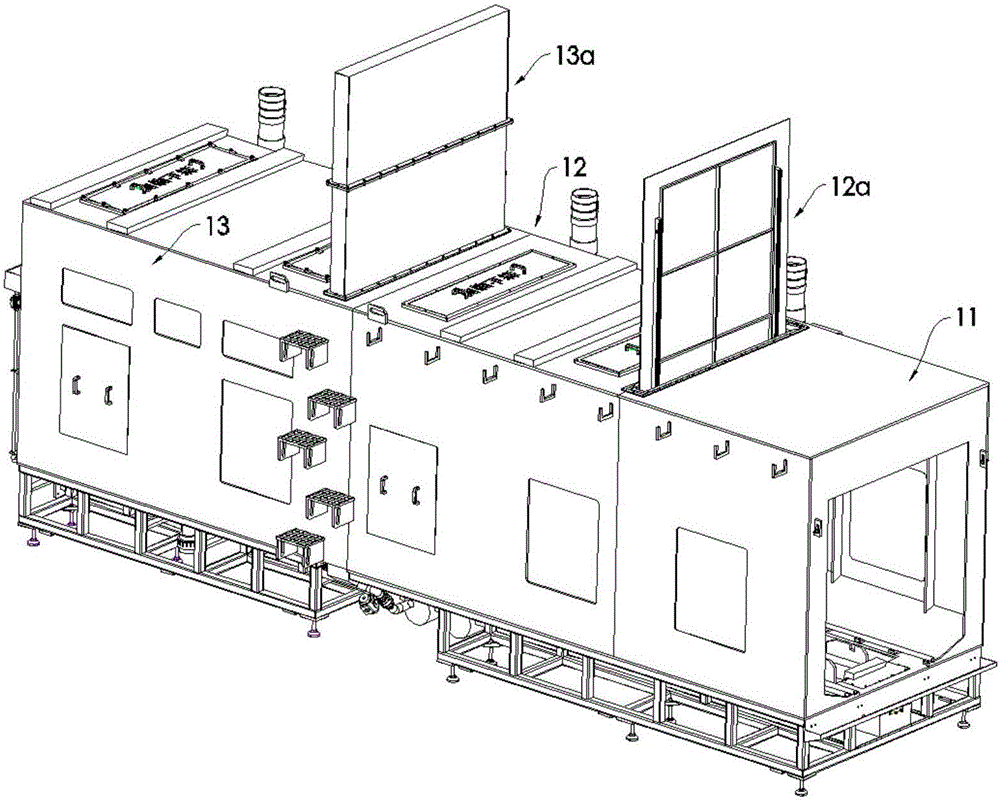

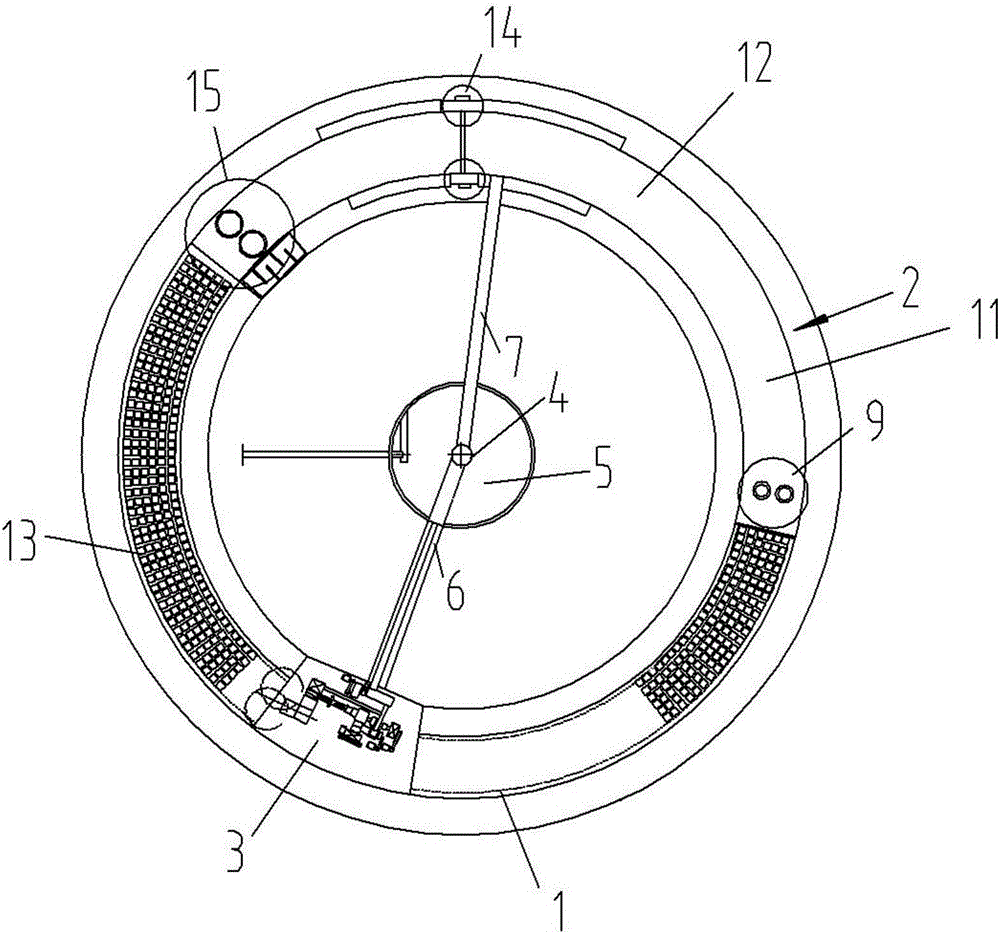

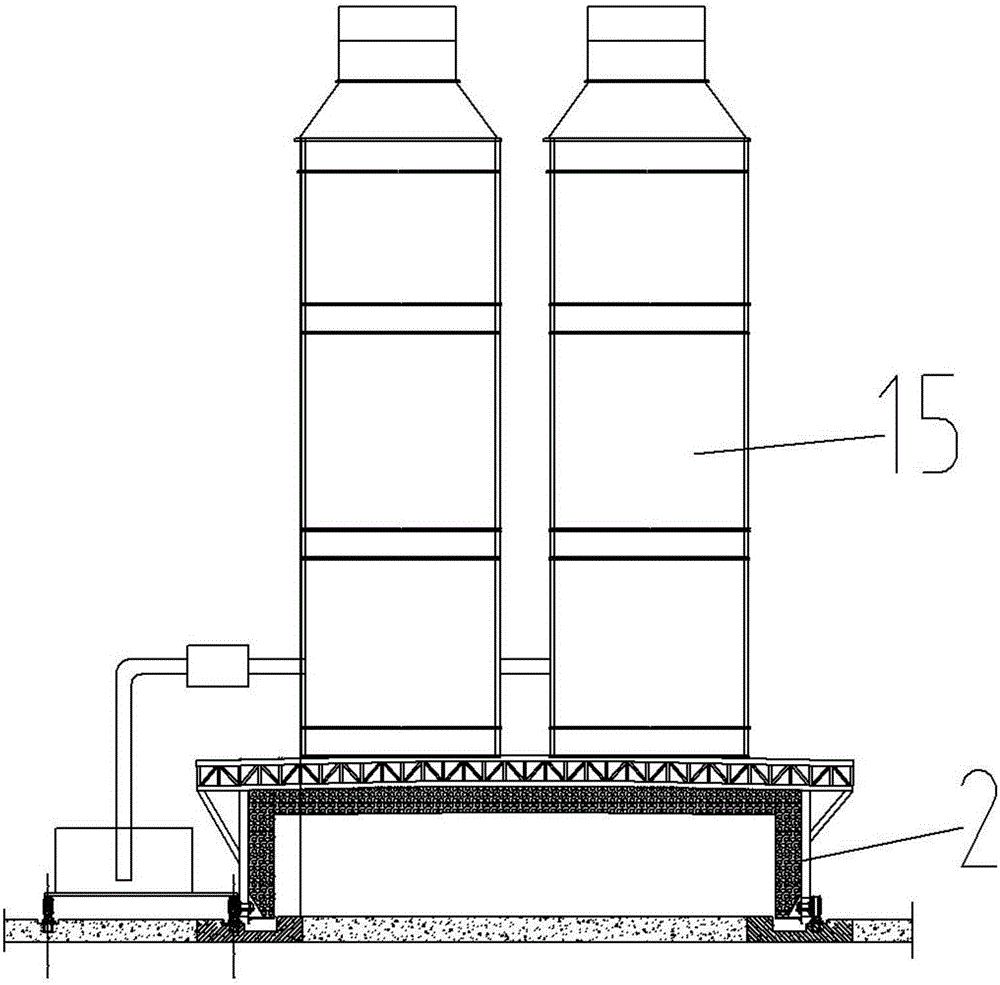

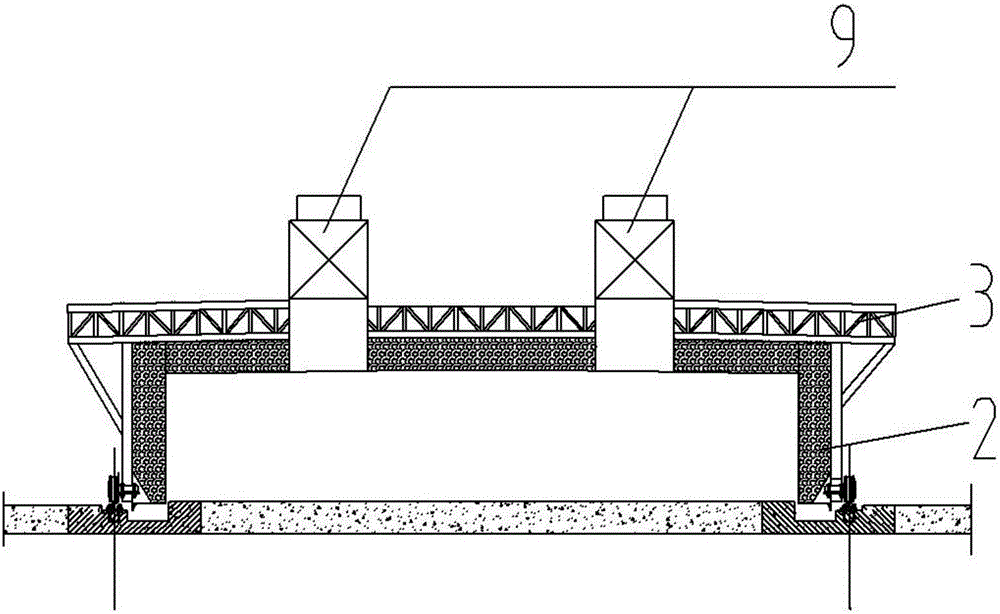

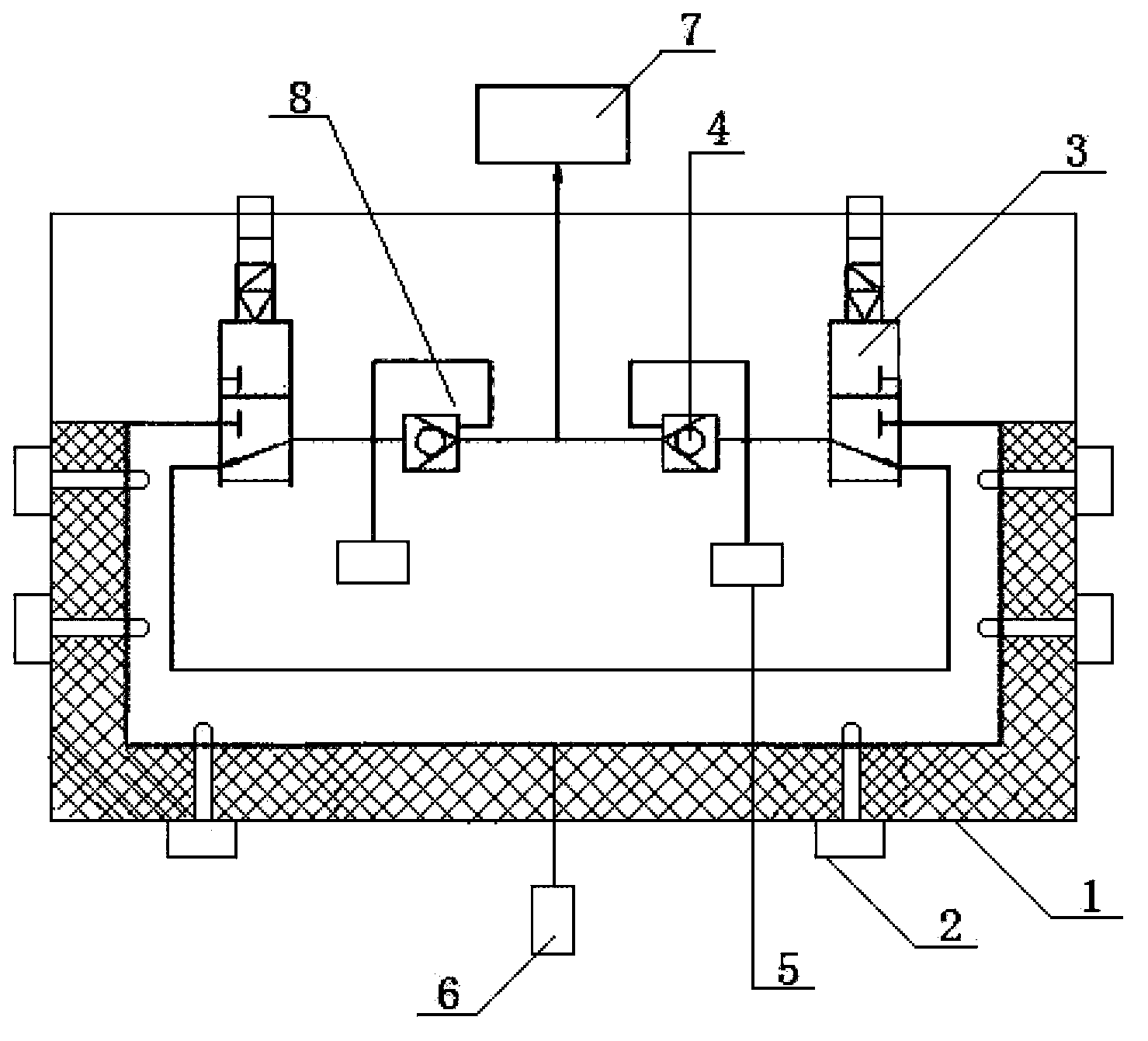

Annular movable tunnel kiln production line layout process

InactiveCN106839758AAvoid clutterOvercome the failure rateMaintainance of heating chambersFurnace typesTunnel kilnElectricity

The invention relates to a tunnel kiln, in particular to an annular movable tunnel kiln production line layout process. The annular movable tunnel kiln production line layout process adopts a kiln chamber underground material-passing duct, annular track, a kiln body, a forming shop mobile platform, a central power supply and current collecting device and a production water supply pool, wherein the central power supply and current collecting device is arranged at the circle center position of the annular track, the forming shop mobile platform is electrically connected with the central power supply and current collecting device, the kiln body is electrically connected with the central power supply and current collecting device, a kiln head portion is provided with a flue gas purifying device arranged at a kiln top and moving with the kiln body, an agent purifying pool platform moves with the kiln body, a moisture discharging flue and a moisture discharging fan are arranged at the top, a smoke sucking hot air channel is arranged in the middle of the kiln and arranged at the bottom of the side, a kiln tail portion is provided with a forced air feeding and oxygen supply device and a tail door, and an air inlet fan is arranged at the top of the kiln tail portion of the kiln body. By adopting the scheme, the annular movable tunnel kiln production line layout process has the advantages of being low in fault rate, low in maintenance cost and high in yield.

Owner:周大林

Novel three-way electromagnetic valve monitoring mechanism of pneumatic clutch

Disclosed is a novel three-way electromagnetic valve monitoring mechanism of a pneumatic clutch. A fastening stud is arranged on a mechanism body, three-way electromagnetic valves are arranged at the upper end of the mechanism body, air inlets of the three-way electromagnetic valves are connected in parallel, the mechanism body is connected with a single-supply steam source, one-way control valves are arranged on one side of the middle of the mechanism body, the outlet ends of the one-way control valves are connected through a tee joint and then are connected with a clutch air cylinder, the one-way control valves are connected with outlets of the three-way electromagnetic valves at the same time, one ends of two pressure sensors are connected with the outlets of the three-way electromagnetic valves, and the other ends of the two pressure sensors are in abutting joint with a control loop pipe.

Owner:XUZHOU KAILONG MINING SCI & TECH DEV

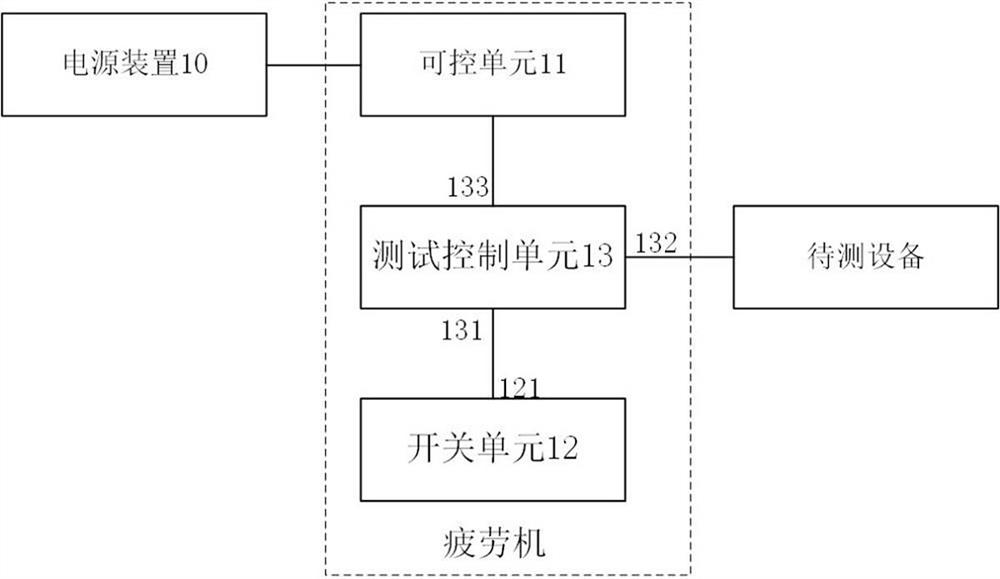

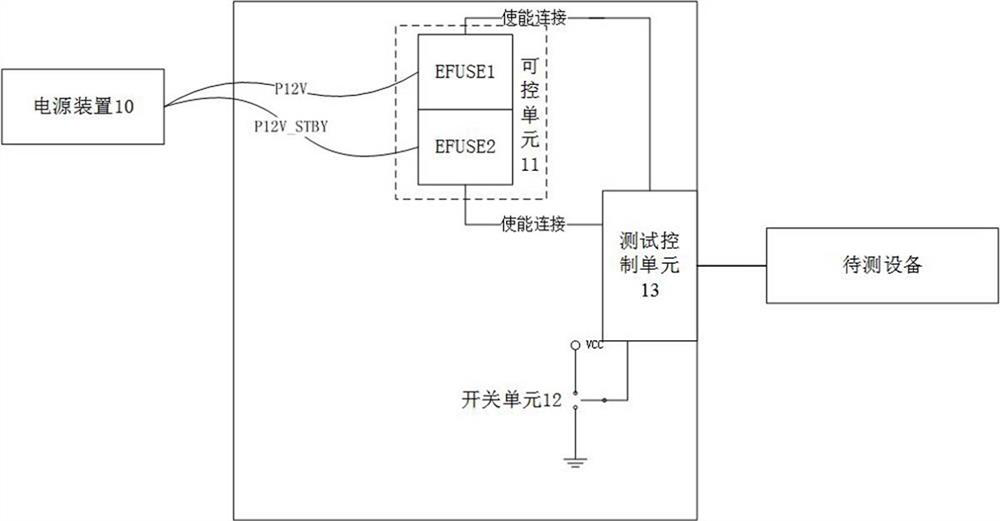

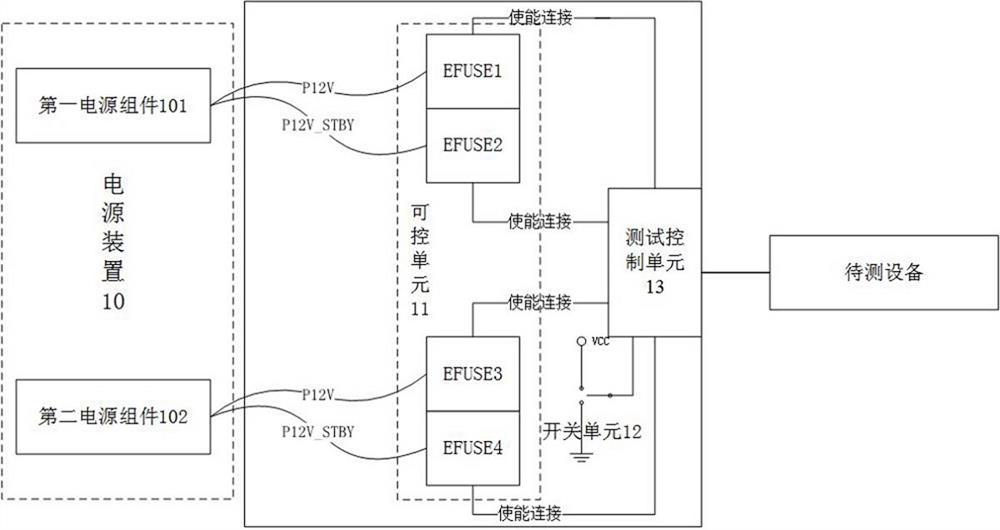

Fatigue machine, equipment power-on and power-off testing system and power-on and power-off testing method

ActiveCN113589092AOvercome efficiencyOvercome the failure rateElectrical testingAutomotive engineeringElectrical and Electronics engineering

The invention relates to the technical field of electronic equipment testing, and discloses a fatigue machine, an equipment power-on and power-off testing system and a power-on and power-off testing method. The fatigue machine comprises a controllable unit, a switch unit and a test control unit. The controllable unit is connected with a power supply device of to-be-tested equipment, a first enabling end of the test control unit is connected with the controllable unit, an input end of the test control unit is connected with the to-be-tested equipment, and a control end of the test control unit is connected with a movable end of the switch unit. The test control unit determines the corresponding performance test based on the connection mode of the movable end and the fixed end, and controls the on / off between the controllable unit and the power supply device based on the received state signal of the to-be-tested equipment, so as to carry out the power-on and power-off performance test of the to-be-tested equipment. According to the invention, the intelligent testing of the power-on and power-off performance of the to-be-tested equipment by the fatigue machine is realized, the problems of high failure rate and high failure rate of a mechanical switch are solved, the service life of the fatigue machine is prolonged, and the testing efficiency is improved.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

Hydraulic adjusting frame structure of forging press

InactiveCN104128550ASimple structureShrinkable and easy to moveForging/hammering/pressing machinesHydraulic cylinderMechanical engineering

Disclosed is a hydraulic adjusting frame structure of a forging press. A rotating arm and a gear are arranged in an inner cavity of a transmission frame, a positioning key and a gear positioning key are arranged on the rotating arm and the gear respectively, a rotating shaft sequentially penetrates through a shaft hole of a mechanism body, a shaft hole of the transmission frame, a shaft hole of the rotating arm and a shaft hole of the gear to be connected with the other end of the mechanism body, the rotating shaft is fixed through the positioning key and the gear positioning key, one end of a cylinder body of a hydraulic cylinder is hinged to the rotating arm through a hinge pin, and the other end of the cylinder body of the hydraulic cylinder is connected with the mechanism body through a hinge pin.

Owner:XUZHOU KAILONG MINING SCI & TECH DEV

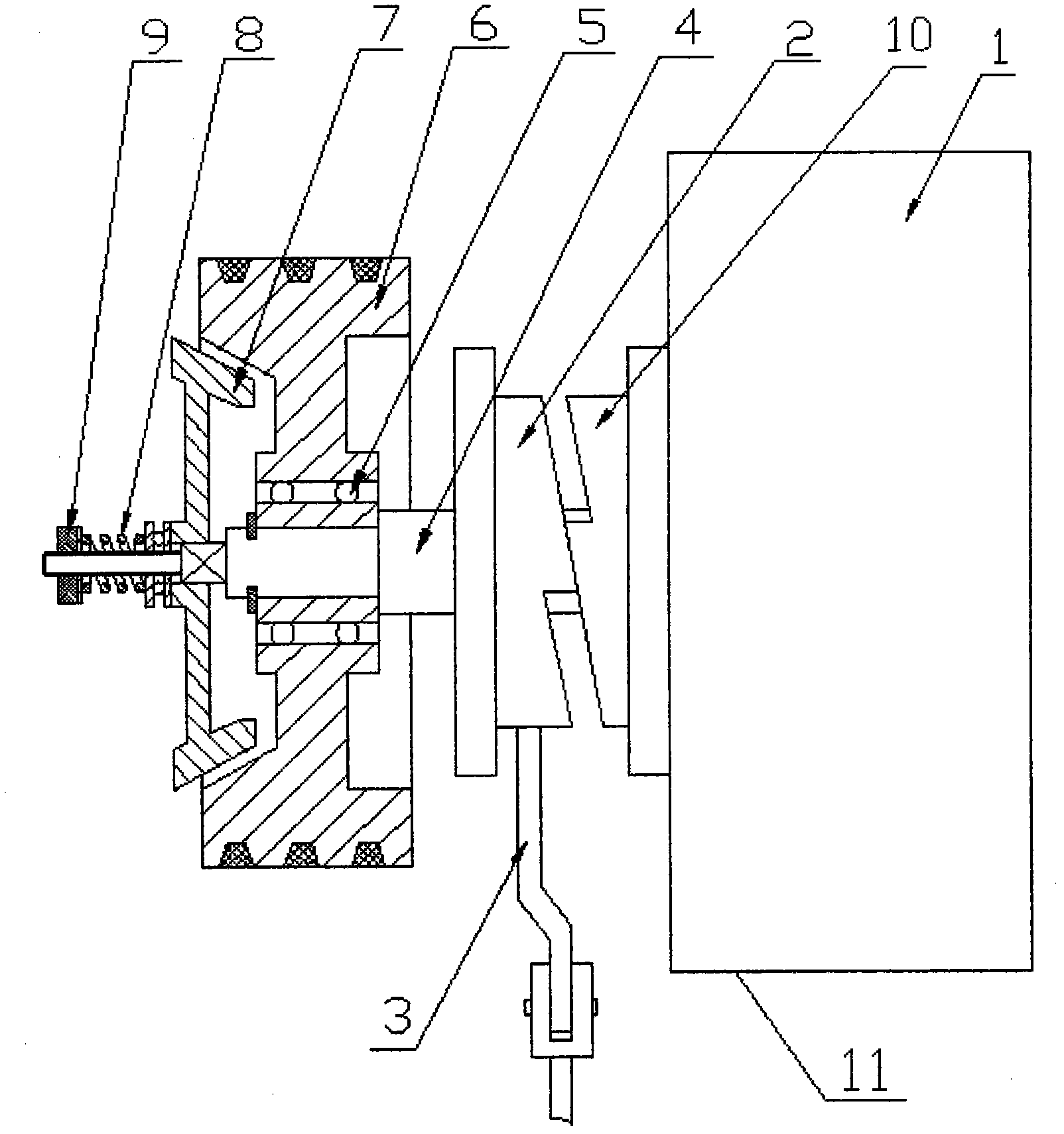

Conical disk type clutch mechanism of machine tool

InactiveCN102606637AOvercome securityOvercoming structural complexityInterengaging clutchesDrive shaftEngineering

Provided is a conical disk type clutch mechanism of a machine tool. A fastening type fit surface is installed on a dual-purpose transmission shaft on one side of a fixed gear box, a rotatable fit surface and the fastening type fit surface are oppositely installed on the dual-purpose transmission shaft, a single-acting operation rod is connected with the rotatable fit surface, a positioning fly wheel is installed on the dual-purpose transmission shaft on the outer side of the rotatable fit surface through a multi-position bearing, and a multi-position driving disk is a cone-shaped body and installed on the transmission shaft on the outer side of the positioning fly wheel through a single key. A tightening spring is installed on the dual-purpose transmission shaft on the outer side of the multi-purpose driving disk through locking nuts.

Owner:杜玉芝

Novel horizontal lathe chuck mechanism

InactiveCN102642030ANot easy to deform and damageSimple structureTurning machinesDrive motorEngineering

The invention relates to a novel horizontal lathe chuck mechanism which is provided with a horizontal lathe composed of a horizontal lathe body, a multipurpose chuck, a lathe box and a lathe cantilever; a vertical column is mounted on the lathe box; a slide block is mounted on the middle part of the vertical column; the lathe cantilever is connected with the slide block; a pneumatic mechanism is mounted on the lathe cantilever through an automatic butt joint port; a steam-driven motor mechanism is mounted at the top of the vertical column; one end of a lathe screw rod is in butt joint with an output shaft of the steam-driven motor mechanism through the slide block; and the other end of the lathe screw rod is connected with the slide block in a thread fit form.

Owner:李勇

Vehicle accelerator and brake device

InactiveCN102050092AOvercoming structural complexityOvercome the failure rateFoot actuated initiationsPropulsion unit arrangementsFootplateEngineering

The invention provides a vehicle accelerator and brake device. An accelerator pedal and a brake pedal are arranged in appropriate positions on upper and lower sides of one roller wheel, the roller wheel is mounted in an appropriate position in the middle of a separation plate, the brake pedal is mounted in an appropriate position on the plane of the separation plate under the roller wheel, the brake pedal is mounted in an appropriate position on the plane of the separation plate above the roller wheel, and the accelerator brake and the brake pedal also can be mounted in changed positions on two sides of the roller wheel according to corresponding habits.

Owner:李立飞

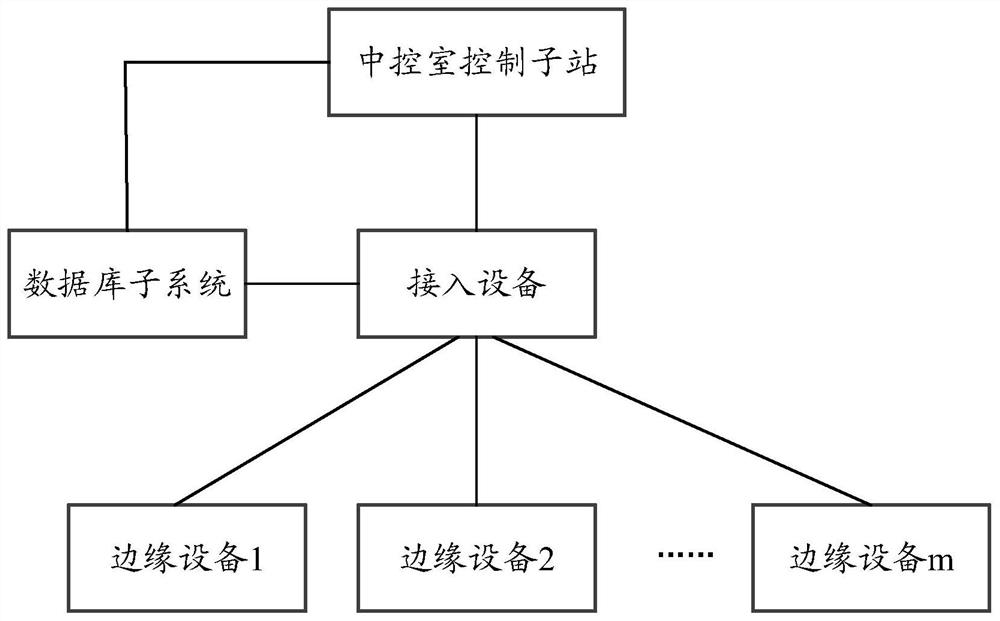

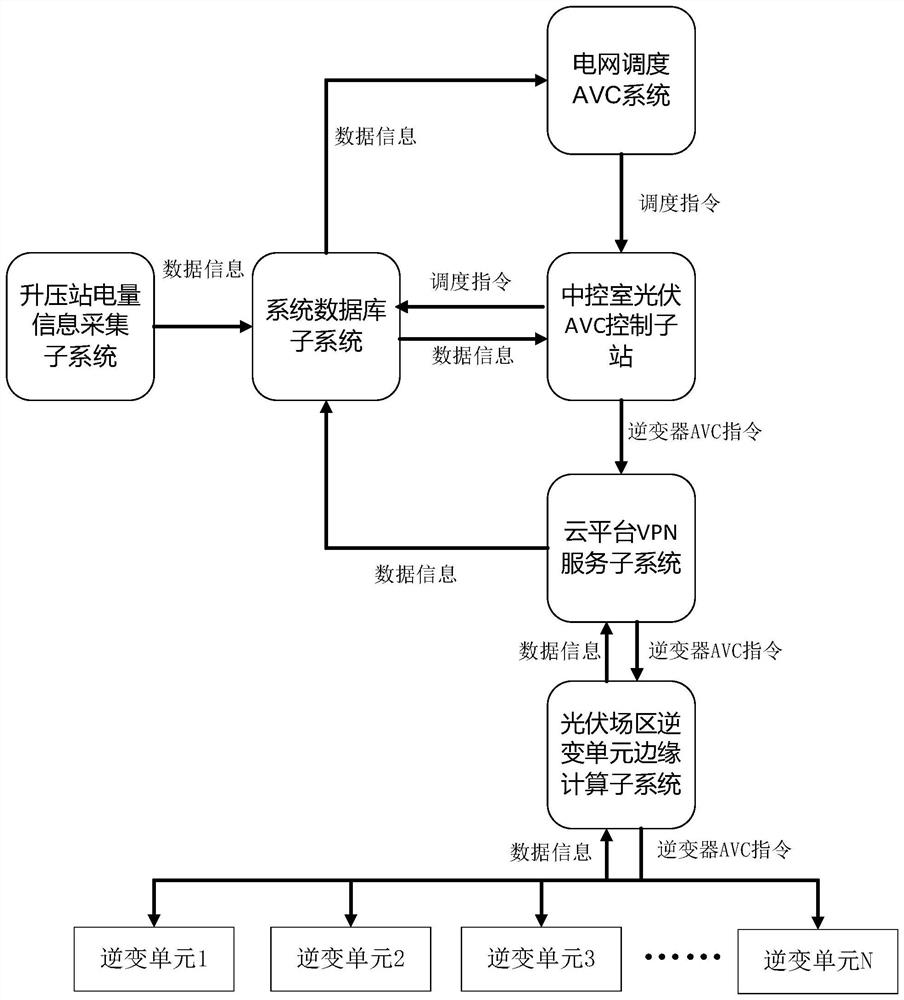

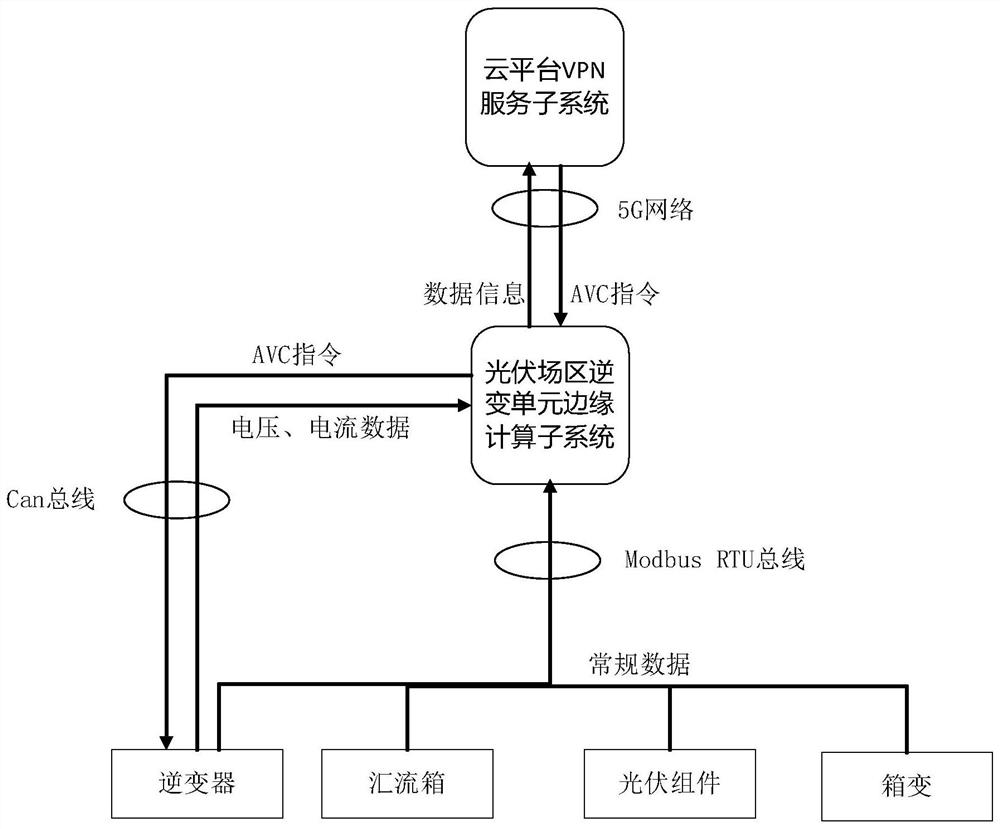

Photovoltaic voltage reactive power automatic adjusting system

PendingCN113013886AOvercoming the high initial investmentOvercome the failure rateSingle network parallel feeding arrangementsAc network voltage adjustmentSystems engineeringPhotovoltaic power plants

The embodiment of the invention discloses a photovoltaic voltage reactive power automatic adjusting system. The system comprises: at least two edge devices used for collecting operation parameters of an inversion unit in a photovoltaic power plant to obtain a first collection result and sending the first collection result; access equipment used for receiving the first collection result and storing the first collection result in a database subsystem; and a central control room control substation used for obtaining the first collection result from the database subsystem after receiving a scheduling instruction, calculating reactive power required to be emitted by each controllable inversion unit according to the adjustment instruction and the first collection result, and sending the reactive power to the central control room control substation. The control instruction used for controlling output of required reactive power is generated for each controllable inversion unit, and the control instruction is sent; and the access equipment is also used for sending the control instruction to the inversion unit through the edge devices after receiving the control instruction.

Owner:BEIJING GUODIAN ZHISHEN CONTROL TONGDY

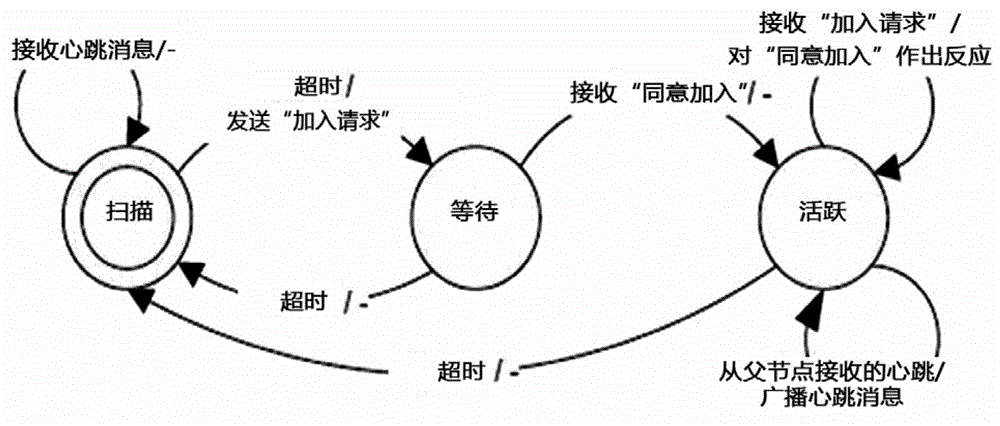

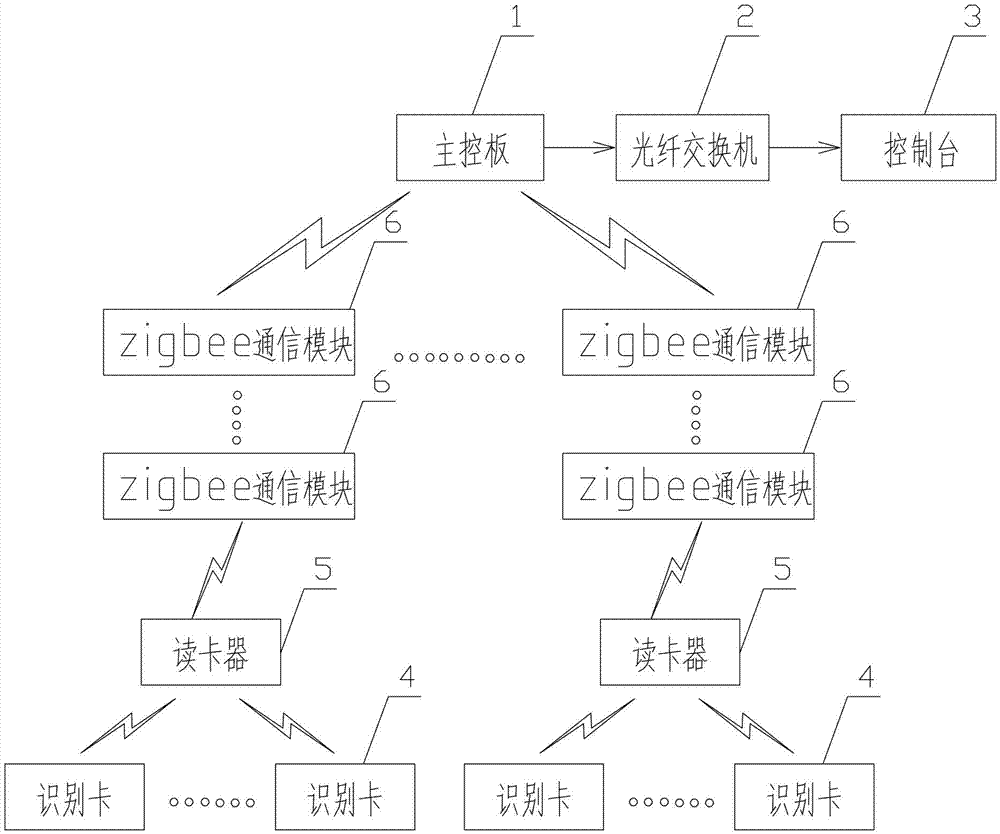

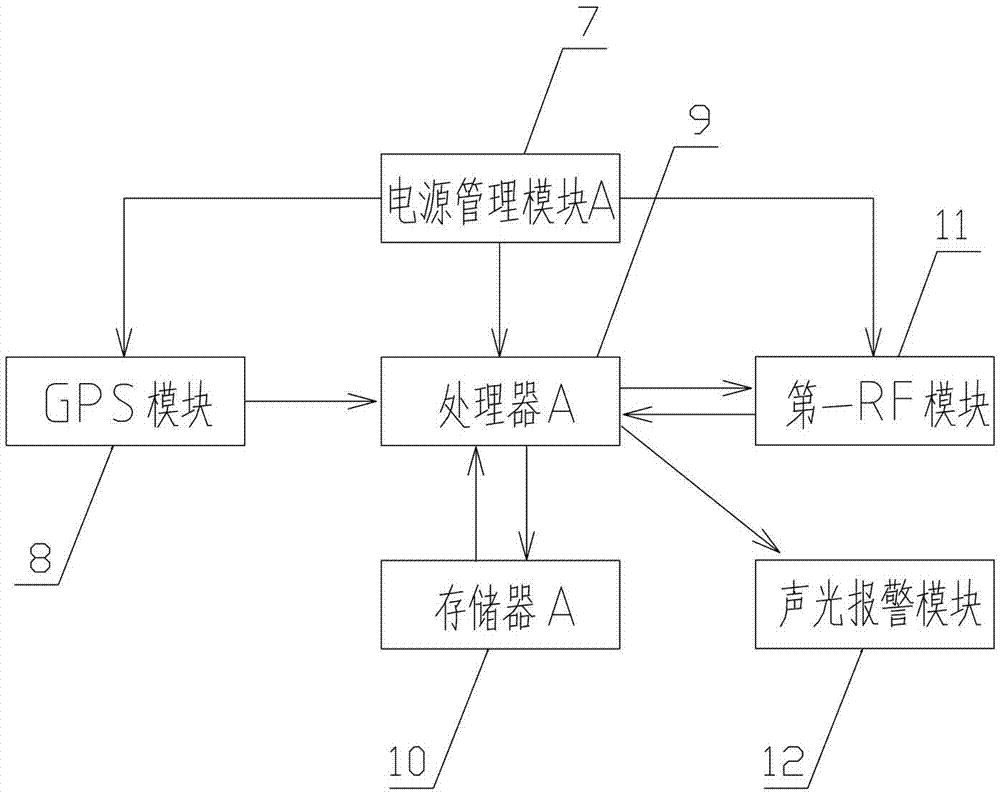

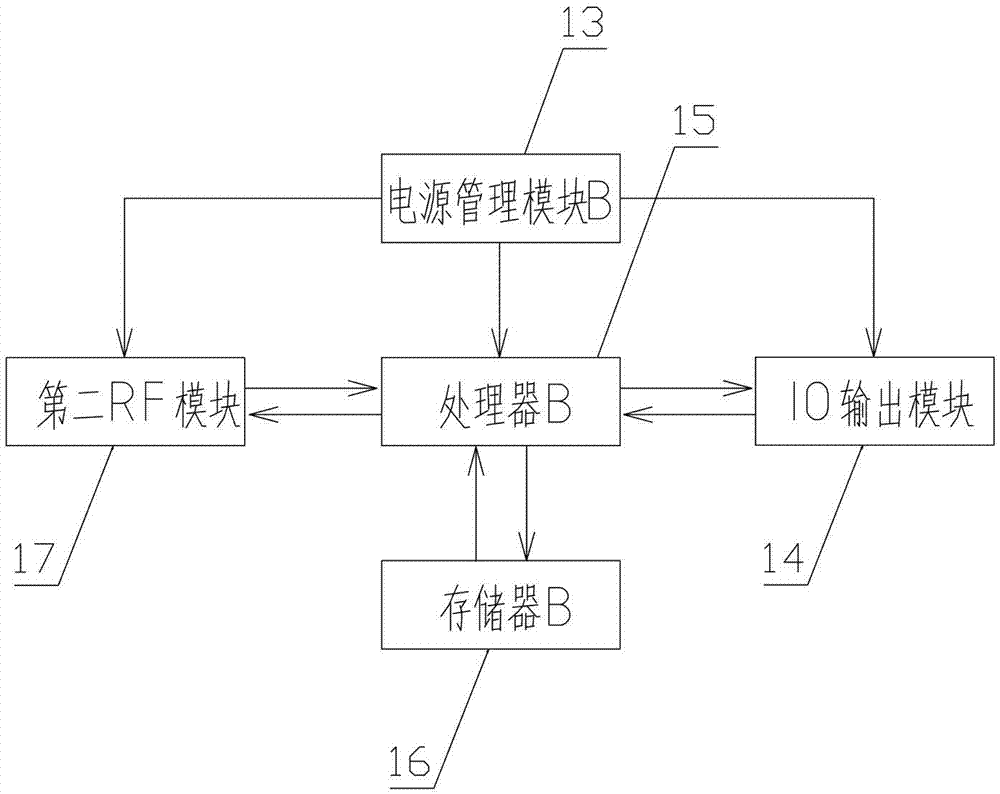

Mine human-machine positioning system based on GIS system

InactiveCN106897644AAchieve precise positioningSimple structureMining devicesTransmission systemsFiberInformation transmission

A mine man-machine positioning system based on GIS system, including an information collection system placed under the mine and an information transmission monitoring system placed on the mine, the information transmission monitoring system includes a main control board, an optical fiber switch and a console, and the control The station is equipped with a GIS system; the information collection system has several information collection units, and the information collection unit is composed of no more than 200 identification cards installed on operators or machines, a card reader and a zigbee network transmission system, each The information collection unit sends the collected information to the main control board, and the main control board transmits the information to the console through the optical fiber switch. The console issues control instructions when an accident occurs in the mine, and controls the corresponding identification card to send out sound and light alarms. Instructions: The present invention adopts zigbee communication technology, which has stable information transmission and high efficiency, realizes precise positioning of operators or machines, and ensures the safety of mine operations.

Owner:SIMPLE HUANGSHI IOT TECH CO LTD

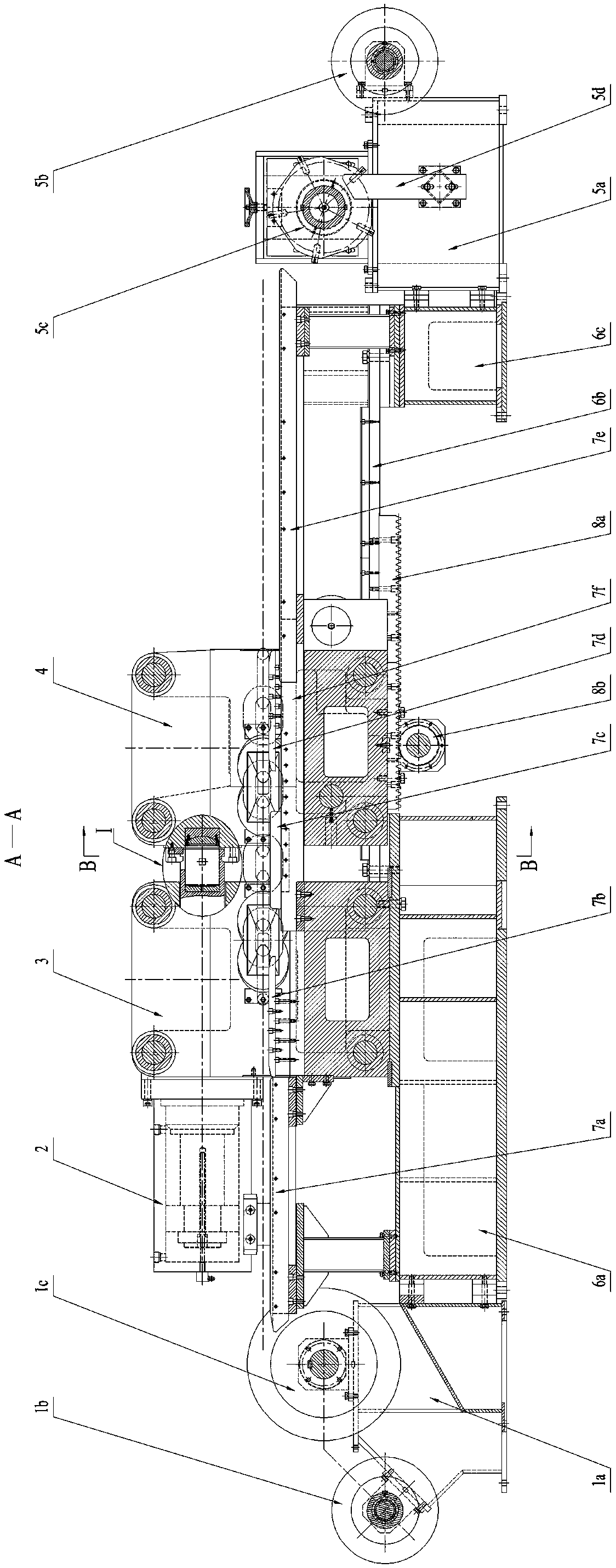

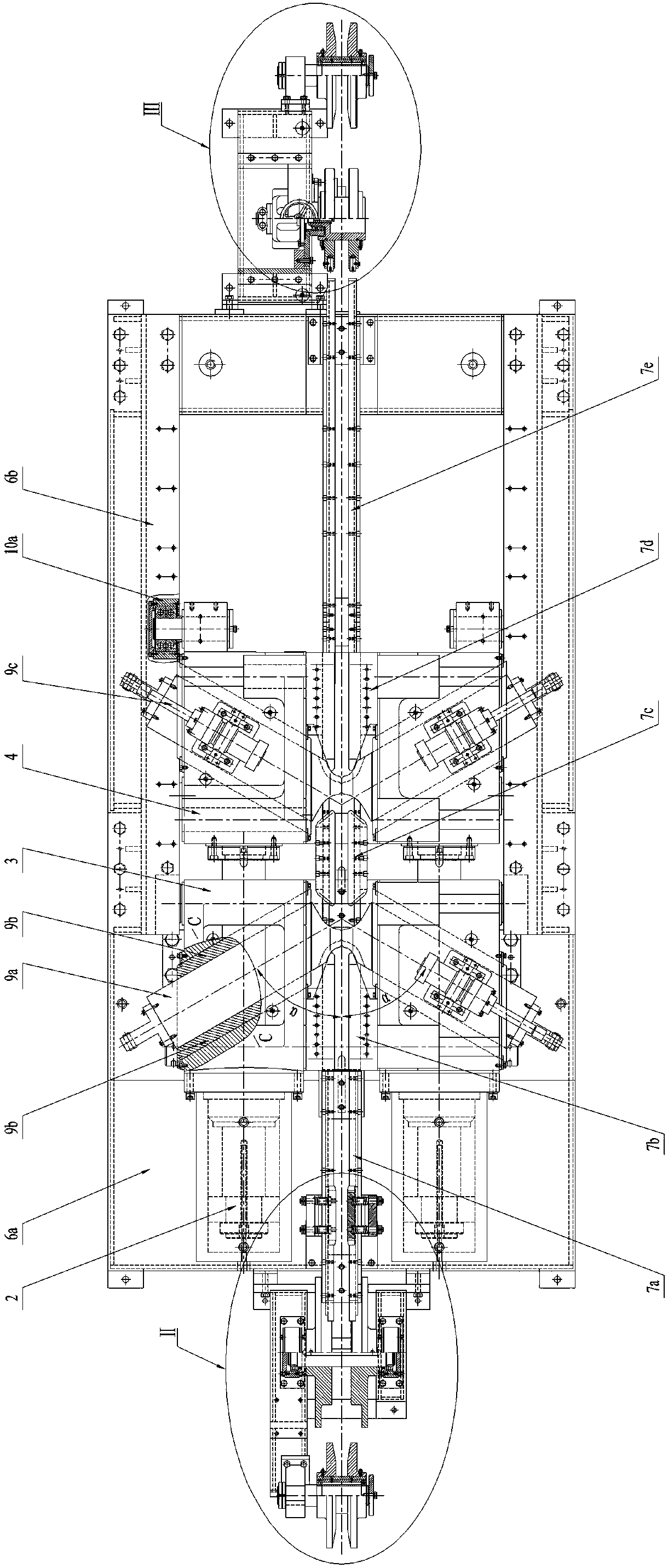

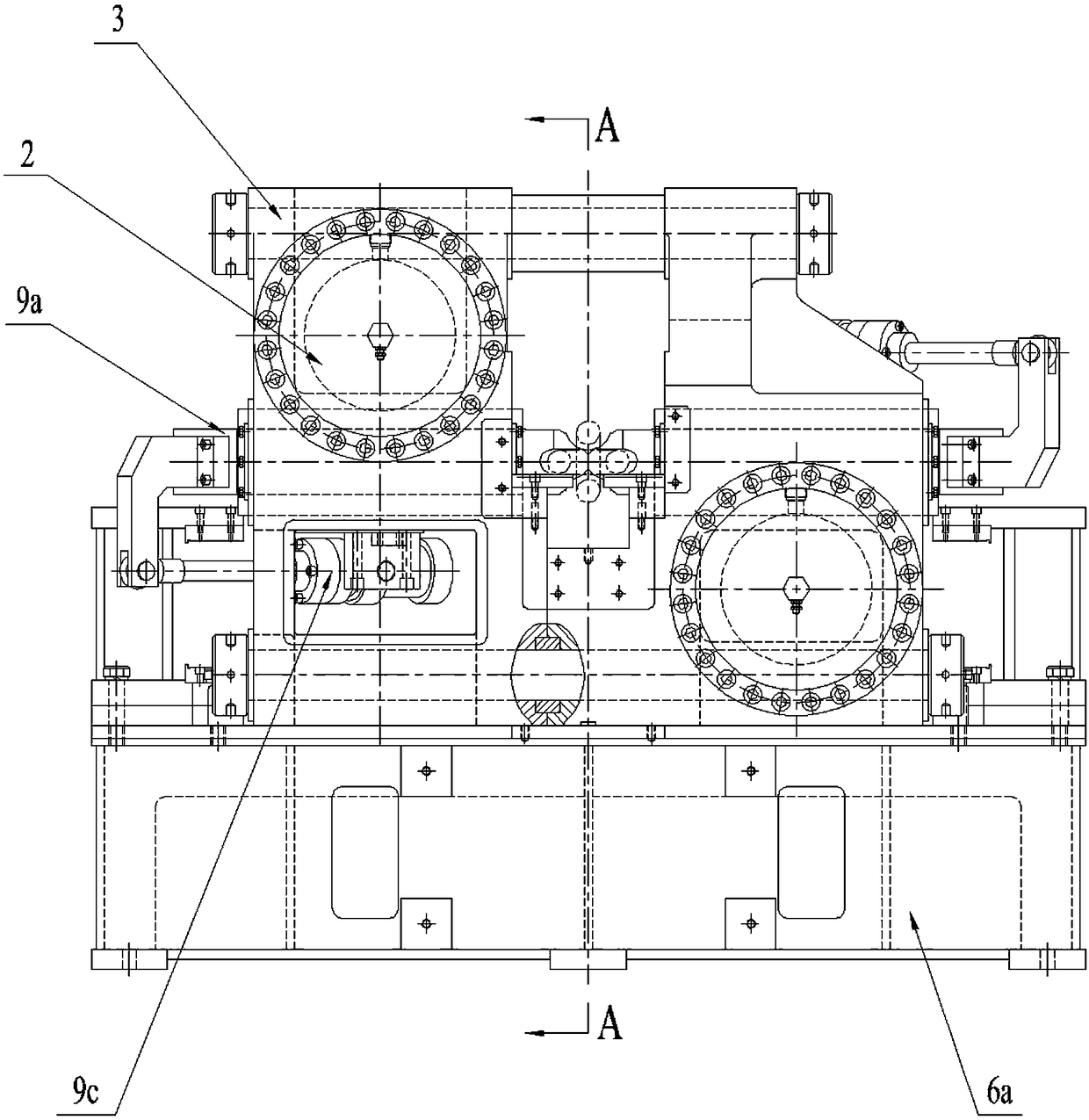

Chain stretching and correcting machine

The invention relates to the technical field of mining circular ring chain production equipment, in particular to a chain stretching and correcting machine. Load borne by the chain stretching and correcting machine during working is extremely high, most existing equipment is high in integration degree, and once parts are damaged, the maintenance cost is high, and the debugging difficulty of the equipment is high. The chain stretching and correcting machine comprises a machine frame, a guide rail assembly, a static machine base, a movable machine base and a stretching clamp assembly; the machine frame is formed by connecting a main base and a tail base through a supporting beam; the static machine base is fixed on the main base; the movable machine base is movably arranged on the supportingbeam in an assembled mode; a clamping head of the stretching clamp assembly is connected with the static machine base and the movable machine base; the guide rail assembly comprises a front supporting plate, a rear supporting plate, a middle guide rail, an input guide rail and an output guide rail which are installed on the static machine base, and the movable machine base and the machine frame.According to the chain stretching and correcting machine, the equipment failure rate and the maintenance difficulty are greatly reduced, the maintenance cost is reduced, the defects that existing stretching equipment is high in fault rate, high in maintenance difficulty, high in cost and the like are overcome, and the continuous operation time of the equipment is prolonged.

Owner:ZHANGJIAKOU NORTH WELDING MACHINE CO LTD

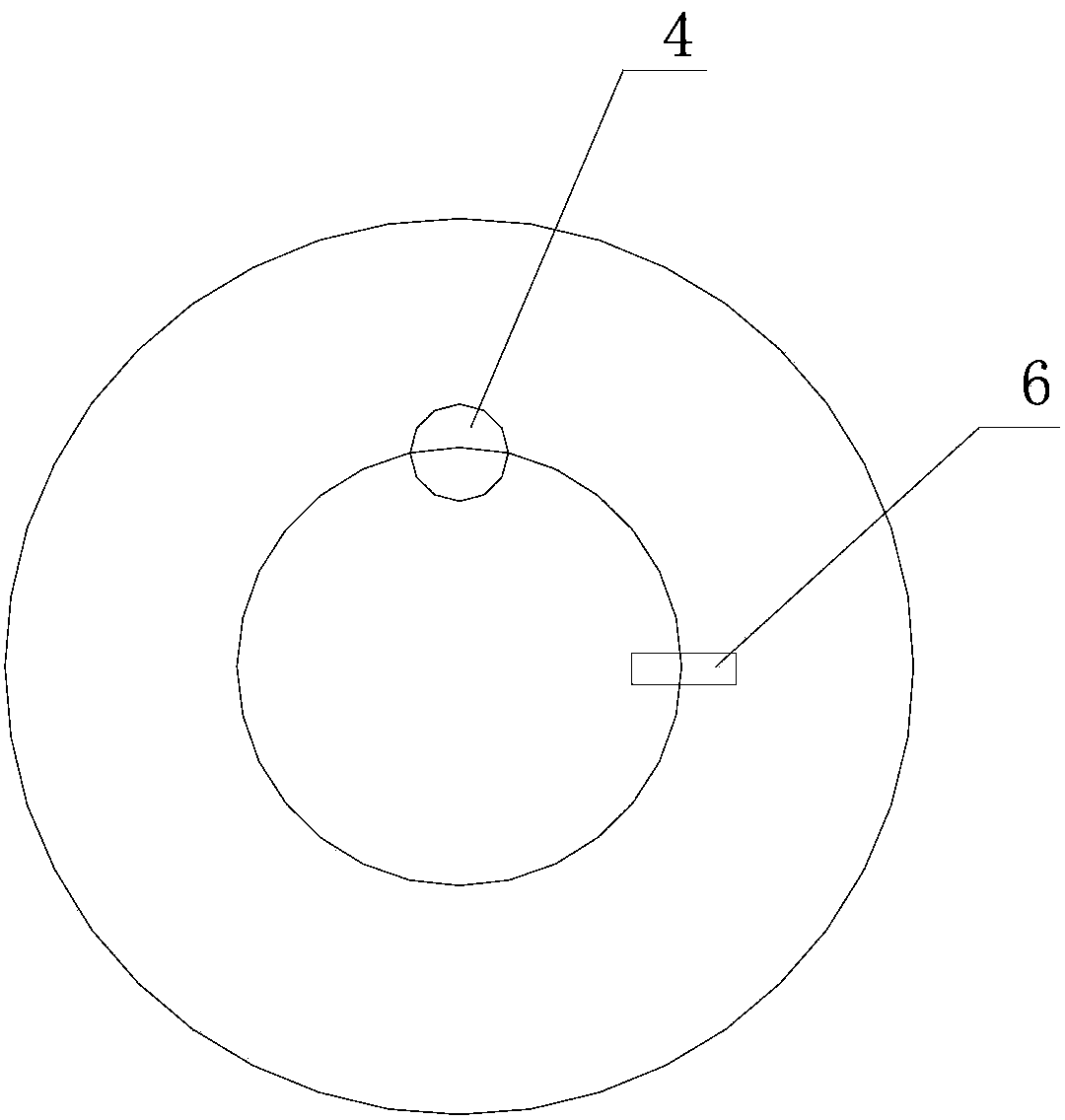

Automatic return gear for motor of intelligent electronic type contactless one-way rotary windscreen wiper

InactiveCN103401362AOvercome structureOvercome longevityMechanical energy handlingStructural associationFailure rateElectric machine

The invention relates to an automatic return gear for a motor of an intelligent electronic type contactless one-way rotary windscreen wiper. The gear is mounted at an end cover of a motor body; a round steel magnet rotating with the gear is embedded on the gear; a Hall switch is arranged on a circuit board; when the gear rotates with the motor and passes through the part below the Hall switch in every turn, the Hall switch acts; when the rotund steel magnet is away from the Hall switch, the Hall switch recovers, so as to detect the spindle origin position. The automatic return gear can be applied to the motor of the windscreen wiper and overcomes the long-existing defects that a mechanical contact type motor is cumbersome in structure, short in service life, high in failure rate, unstable in quality, difficulty in mounting.

Owner:张岳峰 +2

Liquid medium separation device

InactiveCN102805969AOvercoming complexityOvercoming demandsMoving filtering element filtersLiquid mediumSpiral blade

A liquid medium separation device has a cylindrical sieve mesh mounted on a round support plate, two elastic membranes are mounted at the bottom of the round support plate and the upper opening part of the cylindrical sieve mesh by an upper and a lower flange respectively, a spiral blade shaft is mounted at the central part of the cylindrical sieve mesh via the round support plate and the upper flange, a mechanical high-frequency vibration exciting device is mounted at the bottom of the round support plate, the abovementioned parts are mounted in the central part of a housing via the elastic membranes at the upper and lower parts of the cylindrical sieve mesh and mounted above a base, a motor is mounted and fixed on a central shaft at the bottom of the base, a flexible shaft coupling is connected with the spiral blade shaft, and an upper cover is mounted and fixed to the upper opening part of the housing.

Owner:魏家全

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com