Combined steam jet vacuum pump system capable of utilizing exhaust heat

A jet vacuum pump and steam technology, applied in the field of power machinery, can solve the problems of not saving too much steam consumption and increasing maintenance workload, and achieve the effects of overcoming less energy saving, ensuring long-term reliability and stability, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

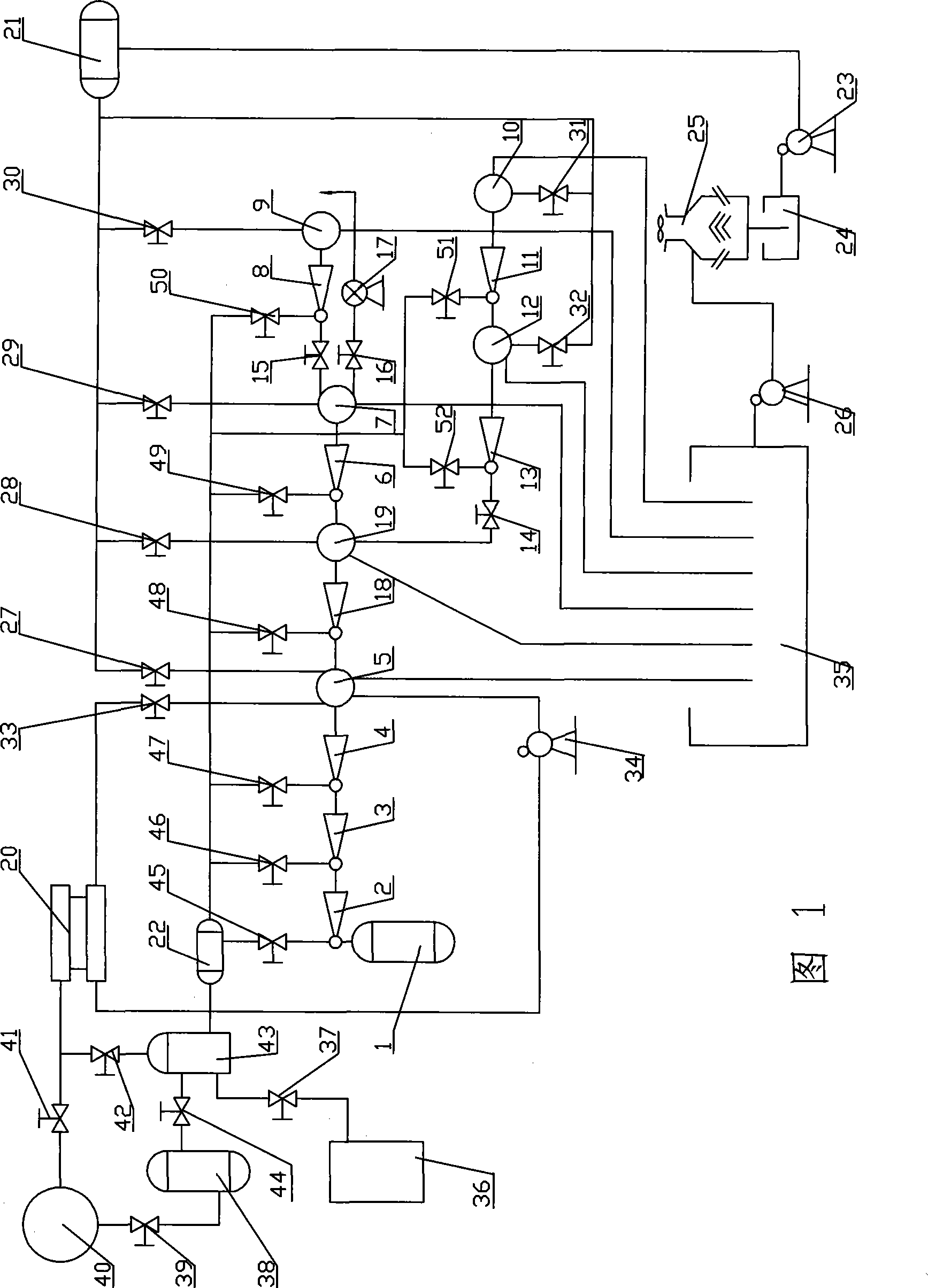

[0011] In conjunction with the accompanying drawings, the overall structure of the present invention and its working principle are described in detail:

[0012] The waste heat combined steam jet vacuum pump system that can be used includes the existing steam jet vacuum pump unit, especially after the first, second, third, fourth or fifth stage ejector of the steam jet vacuum pump unit Add an ejector and condenser between the condenser and the ejector and condenser group behind it, wherein the ejector and condenser group are one group, two groups, three groups or four groups, on the condenser in front of an ejector It is connected with a water ring vacuum pump to form a new steam jet vacuum pump unit. The new steam jet vacuum pump unit is equipped with an absorption refrigerator, a water separation drum, a steam distribution drum and a waste heat source device. As shown in Figure 1, it provides a specific embodiment of the present invention. From the existing steam jet vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com