Annular movable tunnel kiln production line layout process

A tunnel kiln and mobile technology, applied in the field of tunnel kiln, can solve the problems of high failure rate of the power supply side of the sliding contact line, high operation and maintenance costs, cluttered and long lines, etc. , Improve the effect of "correct" air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

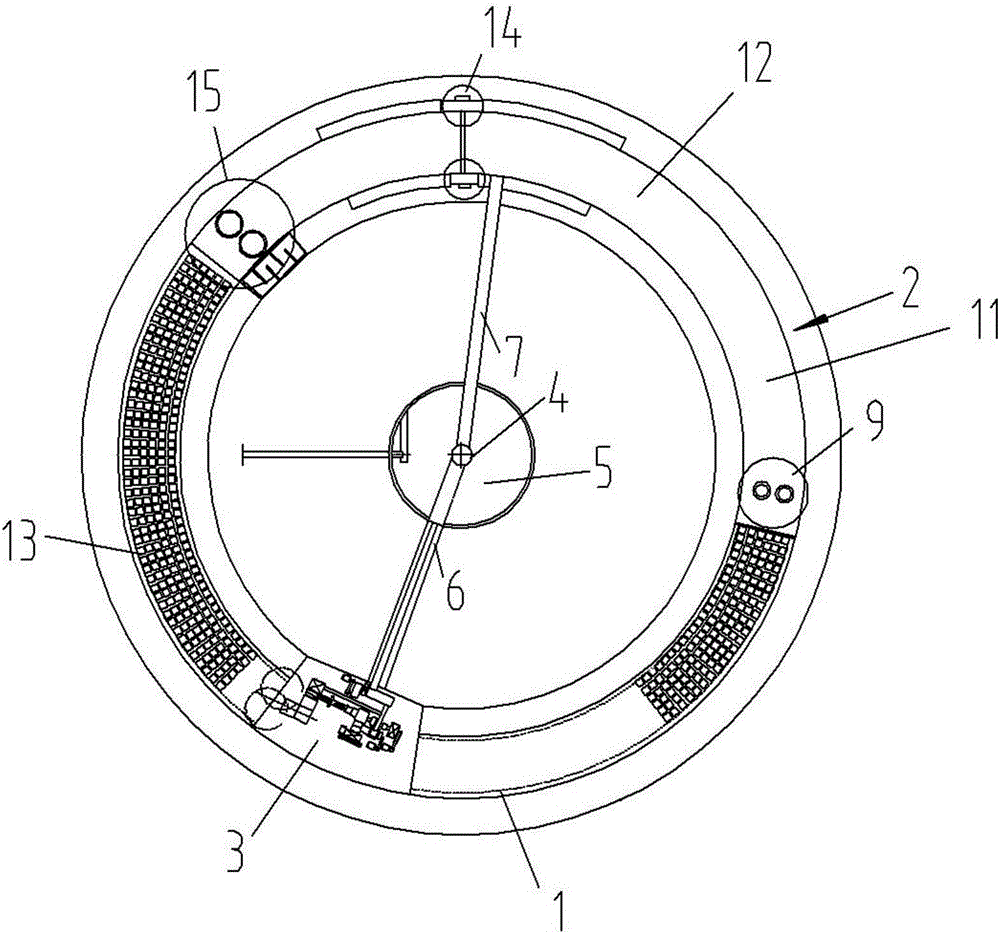

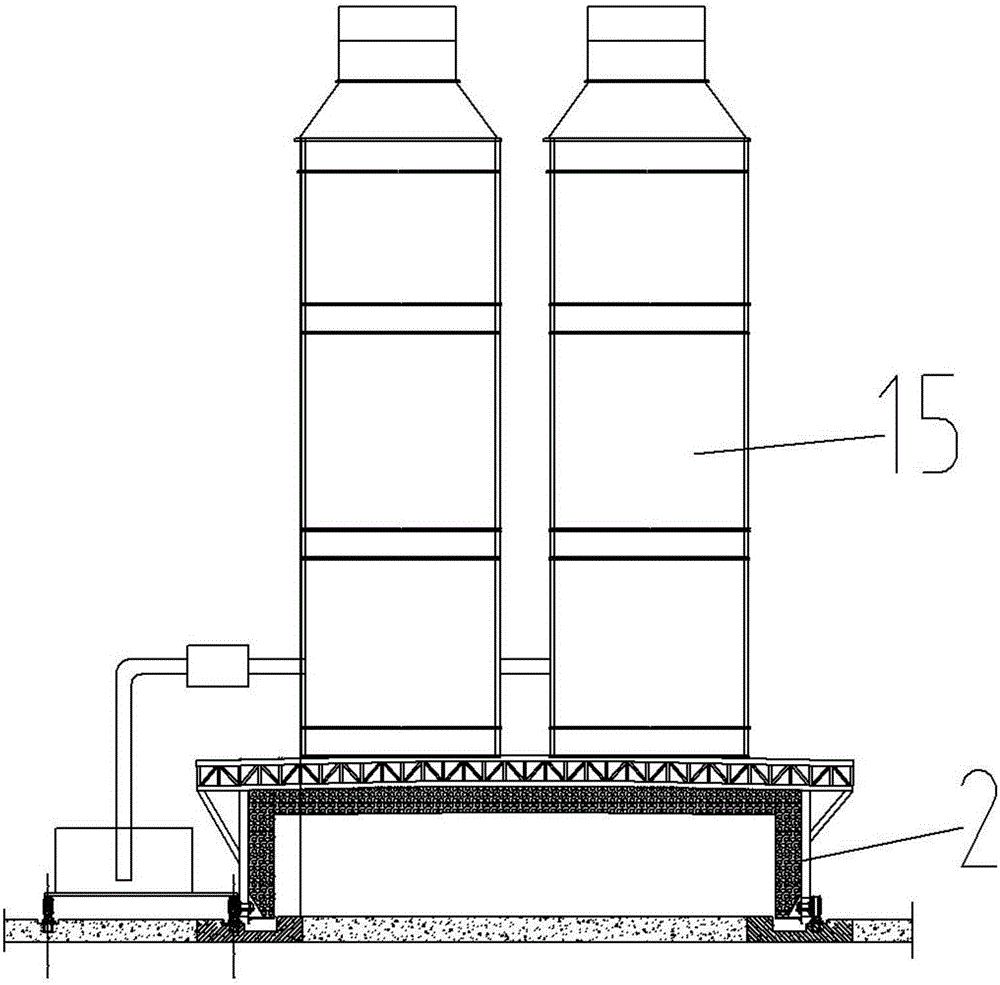

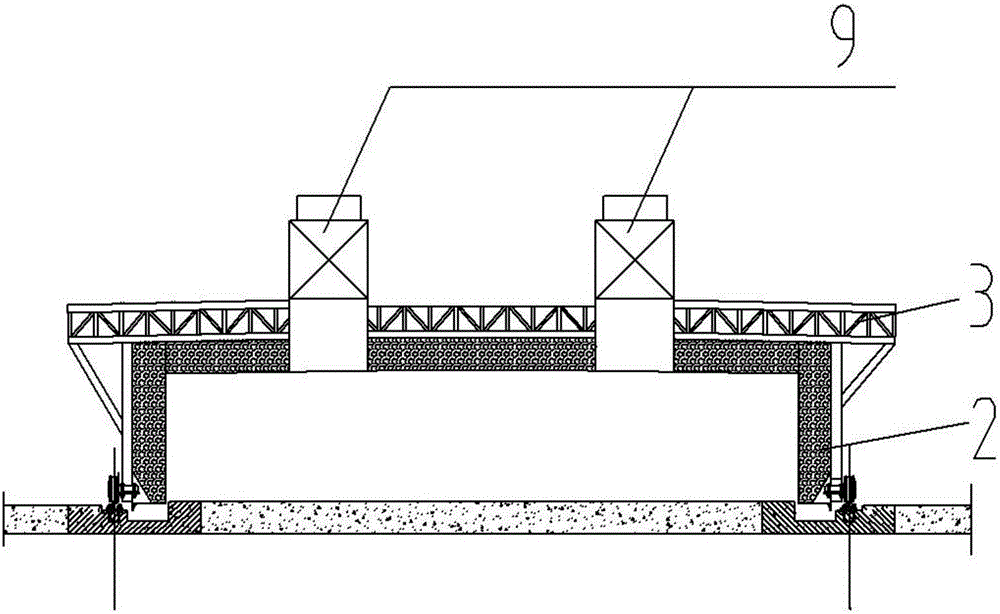

[0021] according to figure 1 , 2 , 3, and 4, the present invention provides a ring-shaped mobile tunnel kiln production line layout process, including the kiln chamber underground material passage, circular track 1, kiln body 2, molding workshop mobile platform 3, and central power supply collector 4 , Production water supply pool 5, the kiln head is equipped with a flue gas purification device set on the top of the kiln and moves with the kiln body, the platform of the purified liquid pool moves with the kiln body 2, the top is arranged with a squall flue and a moisture exhaust fan, and the middle of the kiln is equipped with The side bottom of the smoke hot air passage is arranged, and the forced air oxygen supply device and the tailgate are installed at the tail of the kiln. The central power supply collector 4 is set at the center of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com