Pre-coating film without primer coating, two-way stretch polypropylene film thereof and preparation method of polypropylene film

A polypropylene film, biaxial stretching technology, used in chemical instruments and methods, coatings, flat products, etc., can solve problems such as affecting the brightness of pre-coating films, air pollution, and reducing the yield of laminating films, to overcome production equipment. The effect of complexity, reducing production energy consumption, and simplifying production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

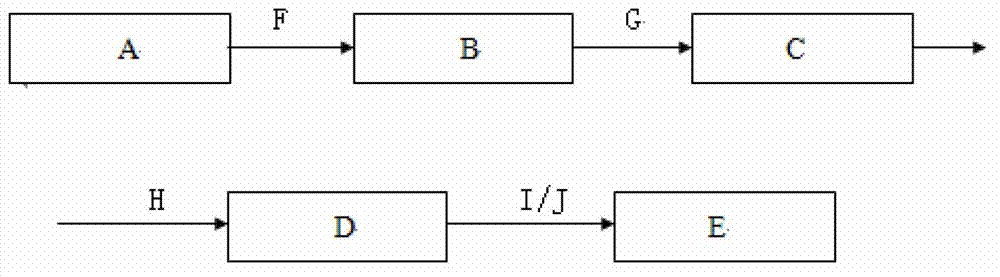

[0047] Specifically this preparation method comprises the steps:

[0048] Firstly, the screened raw material A is pre-mixed according to the formula design. After being evenly stirred, it is sent to the metering silo of the extrusion equipment through the feeding system. The plasticized and uniform melt B is formed; secondly, it is transported to the filter device for filtration through the pipeline, and then transported to the die head for forming through the pipeline, and the melt forming process G is formed by the die head and the casting cast chilling device to form a thick Sheet C; again, the thick sheet C undergoes a biaxial stretching process H to produce a film D; finally, the thickness of the stretched film D is detected and controlled by an online automatic thickness measuring device, and the film D is treated with corona or flame to increase the surface tension. Then the treated film D is rolled into a master roll, and after the master roll is subjected to aging I t...

Embodiment 1

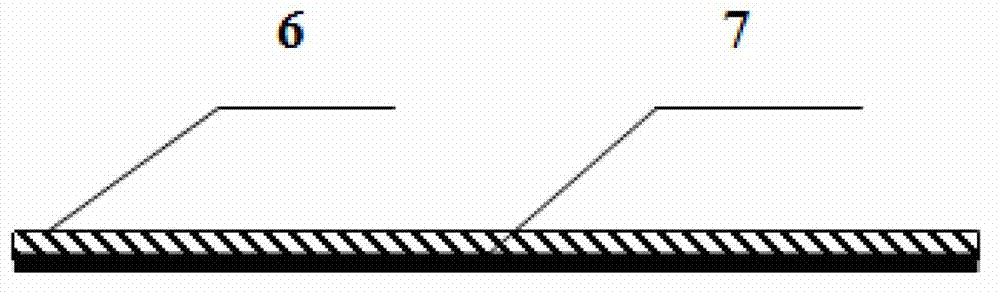

[0051] Embodiment 1: Taking the manufacture of an adhesive-free biaxially oriented polypropylene film 6 with a width of 8 meters as an example, it will be described in detail.

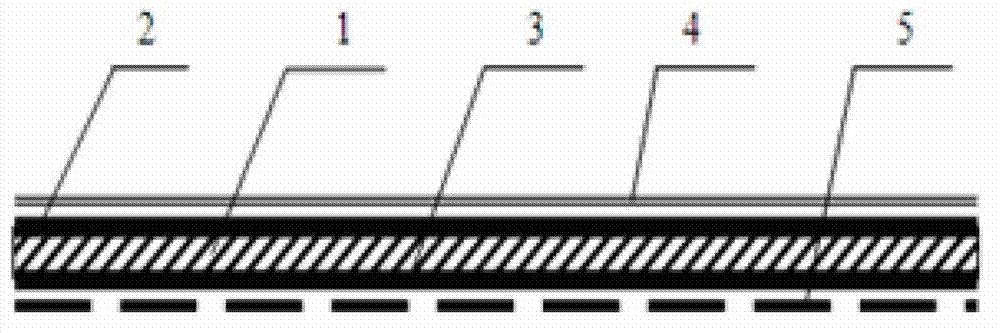

[0052] Such as figure 1 As shown, the functional layer 5 is 90%-97% linear low-density polyethylene (LLDPE) plus 3-10% anti-blocking agent. Among them, companies such as Prime Polymer / EXXON Chemical have corresponding grades of LLDPE, such as LL1002YB of EXXON Chemical. The anti-blocking agent can be general-purpose, such as Schulman AB5 or ABPP05.

[0053] The upper layer 2, the lower layer 3 and the core layer 1 are all 93%-97.5% isotactic polypropylene plus 2.5%-7% antistatic agent. The antistatic agent can be universal, such as Schulman ASPA2485 or domestic AY088.

[0054] The surface layer 4 is 95%-98% matt polypropylene (matt material) plus 2%-5% anti-blocking agent; the matting material is general-purpose, such as: Foshan Suxing: M973, and the anti-adhesive agent is general-purpose Just, suc...

Embodiment 2

[0066] Embodiment 2: Taking the manufacture of an adhesive-free biaxially oriented polypropylene film with a width of 8 meters as an example, it will be described in detail.

[0067] Such as figure 1 As shown, the functional layer 5 is 95% linear low-density polyethylene plus 5% anti-blocking agent. Among them, the linear low-density polyethylene is LL1002YB of EXXON Chemical; the anti-blocking agent is selected from Schulman ABPP05;

[0068] The upper layer 2, the lower layer 3 and the core layer 1 are all 97% isotactic polypropylene plus 3% antistatic agent, and the antistatic agent can be general-purpose, such as Schulman ASPA2485 or domestic AY088.

[0069] (Add 4% antistatic agent to 96% metallocene linear low density polyethylene.)

[0070] Surface layer 4 is 95% isotactic polypropylene plus 5% antiblocking agent. Anti-sticking agent can be general-purpose, such as Schulman ABPP05.

[0071] The thickness of the prepared product is 15 microns, the thickness of the func...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com