Novel horizontal lathe chuck mechanism

A horizontal lathe and lathe technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of easy deformation and damage of the chuck, poor versatility, high failure rate, etc., and achieve not easy deformation and damage, simple structure and low failure rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

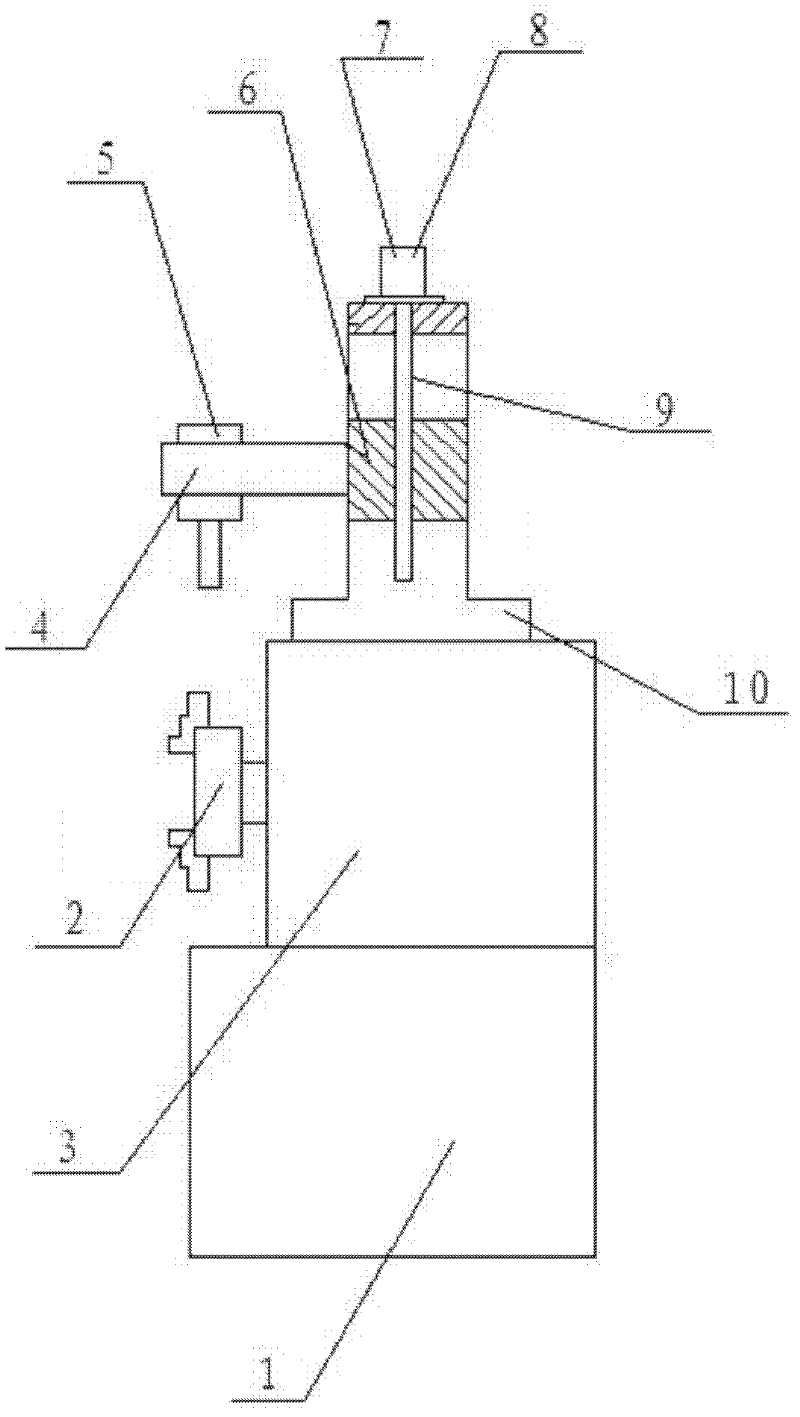

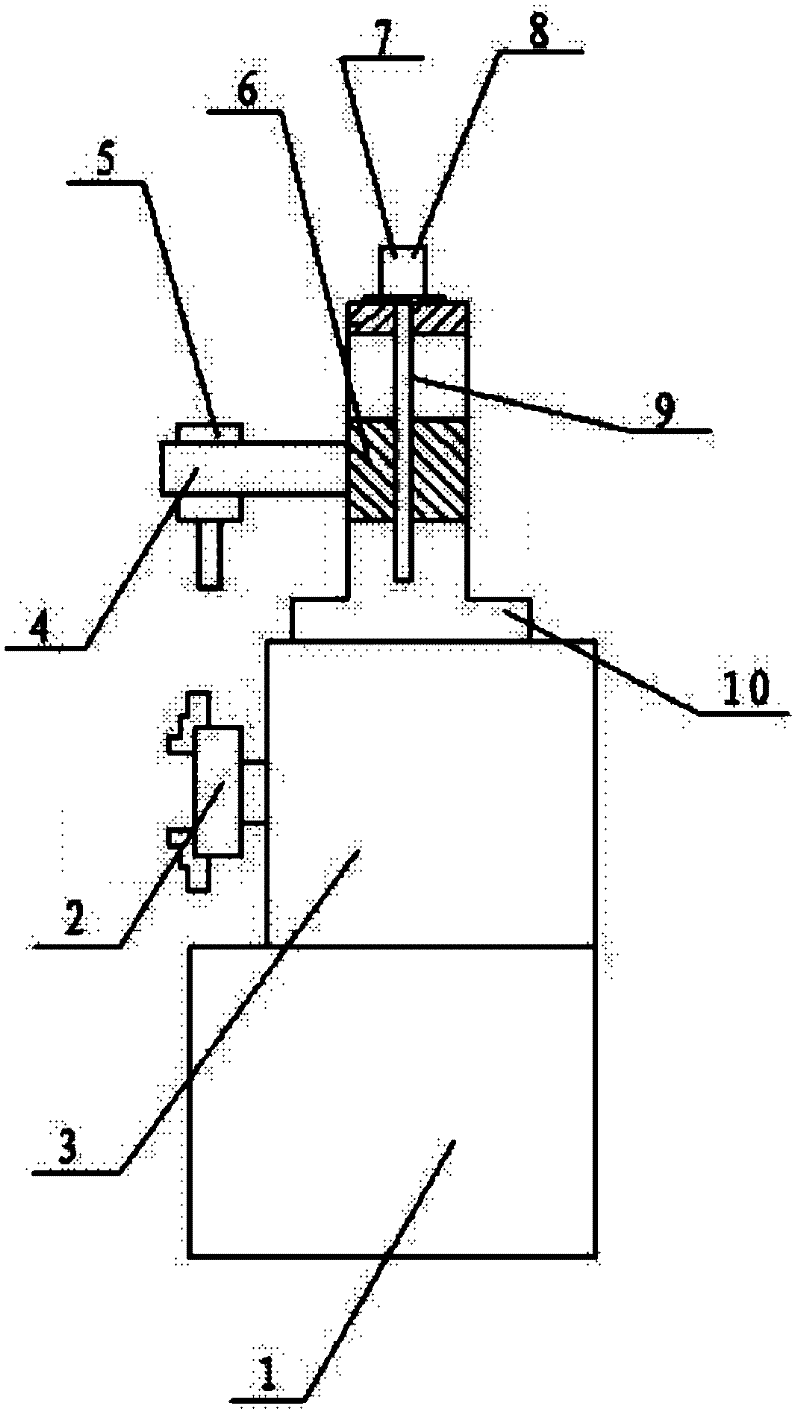

[0009] The chuck mechanism of the horizontal lathe is a horizontal lathe composed of a horizontal lathe body (1), a multipurpose chuck (2), a lathe box (3), and a lathe cantilever (4). The column (7) is installed on the lathe box (3 ), install the slider (6) in the middle of the column (7), connect the lathe cantilever (4) with the slider (6), and install the pneumatic mechanism (8) on the lathe cantilever ( 4), install the steam motor mechanism (10) on the top end of the column (7), and put one end of the lathe screw (9) through the slider (6) to the output shaft of the steam motor mechanism (10) Connect, and the other end is connected with the slider (6) through threaded fit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com