Rack-driven rotational core pulling device at cover half position of injection mold

An injection mold and rack technology, which is applied in the field of rack-driven rotary core-pulling devices, can solve the problems of many potential failure links, high failure rate, and long maintenance time, so as to reduce failures, overcome high failure rates and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

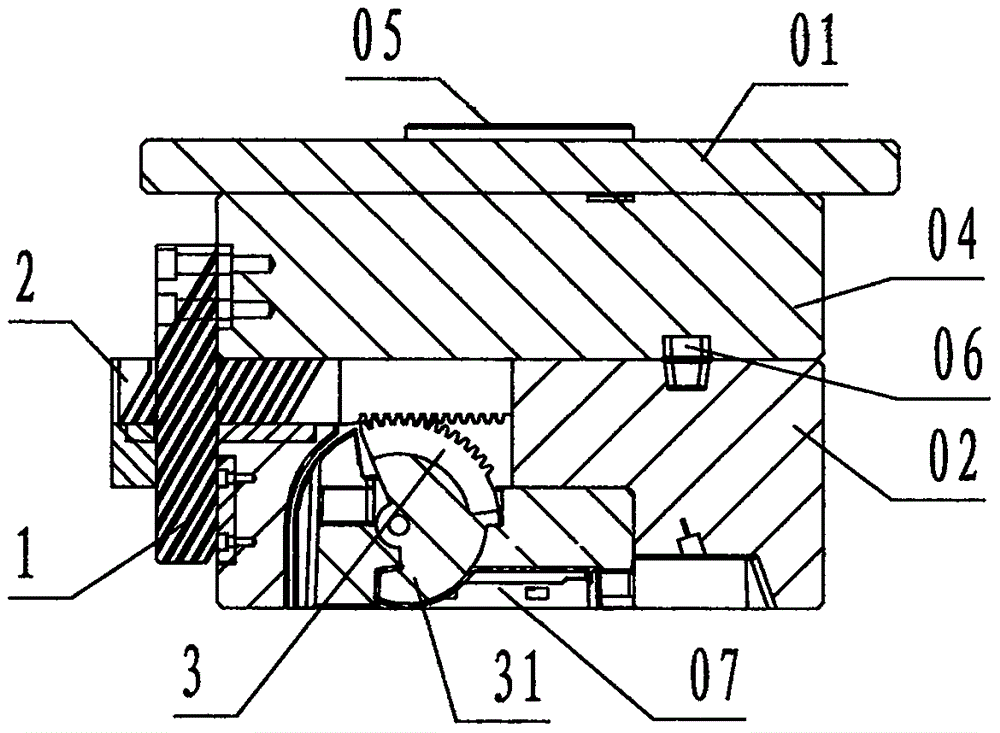

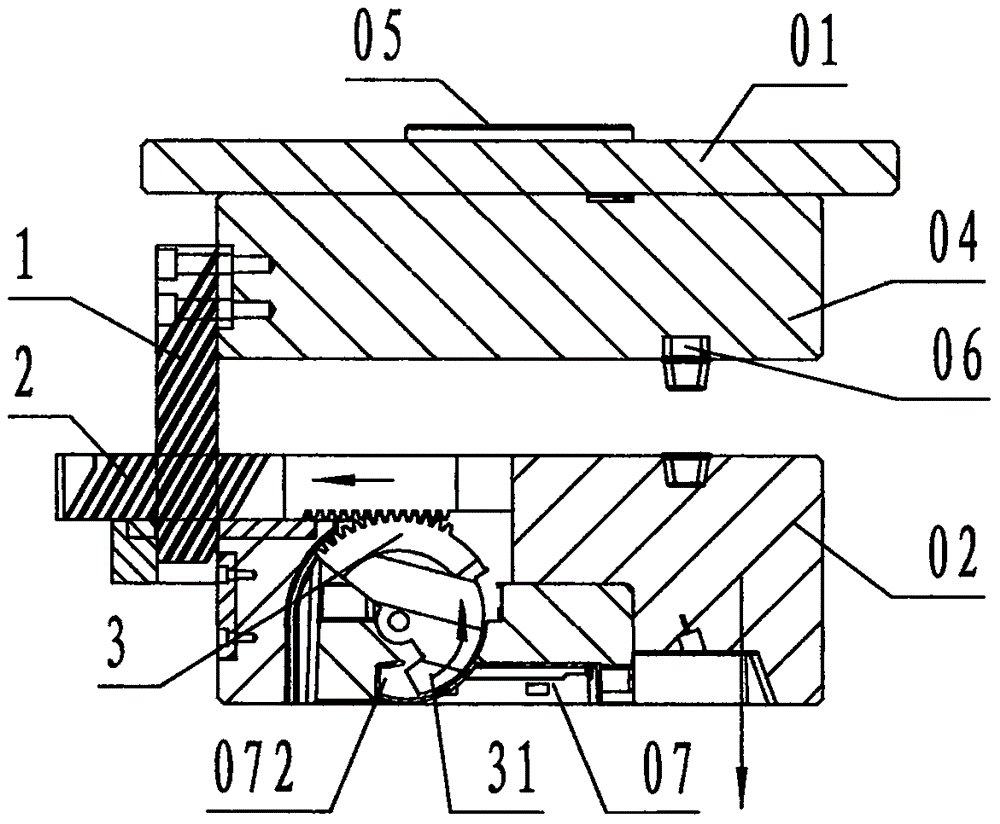

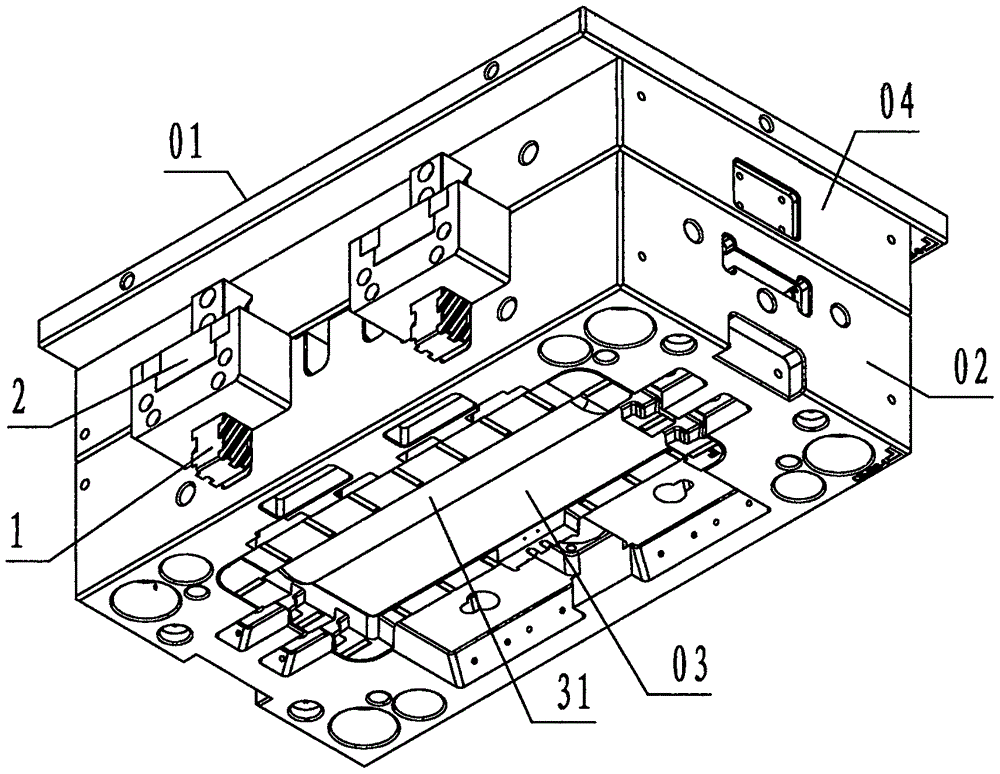

[0020] refer to Figure 1 to Figure 5 , a rack-driven rotary core-pulling device at the fixed part of the injection mold of the present invention includes a longitudinal rack 1, a transverse rack 2, and an arc gear 3, wherein: the longitudinal rack 1 is rectangular As a steel member, the front and rear sides of the longitudinal rack 1 are provided with helical teeth inclined upward from left to right, spaced from each other, and trapezoidal in cross section;

[0021] The transverse rack 2 is a rectangular strip-shaped steel member, and the left part of the transverse rack 2 is provided with a rectangular through hole in the up and down direction, which is called a tooth hole. The helical teeth of 1 correspond to the matching helical grooves; the lower part of the right part of the transverse rack 2 is provided with straight teeth spaced from each other and having a trapezoidal cross-section;

[0022] The arc gear 3 is a steel member in the shape of a fan ring block, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com