Chain stretching and correcting machine

A technology for calibrating machines and chains, applied in the direction of metal chains, etc., can solve the problems of increasing equipment operating costs, increasing equipment debugging difficulties, increasing maintenance and repair costs, etc., to reduce maintenance costs and construction difficulties, and to facilitate daily maintenance. and maintenance, the effect of increasing the duration of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

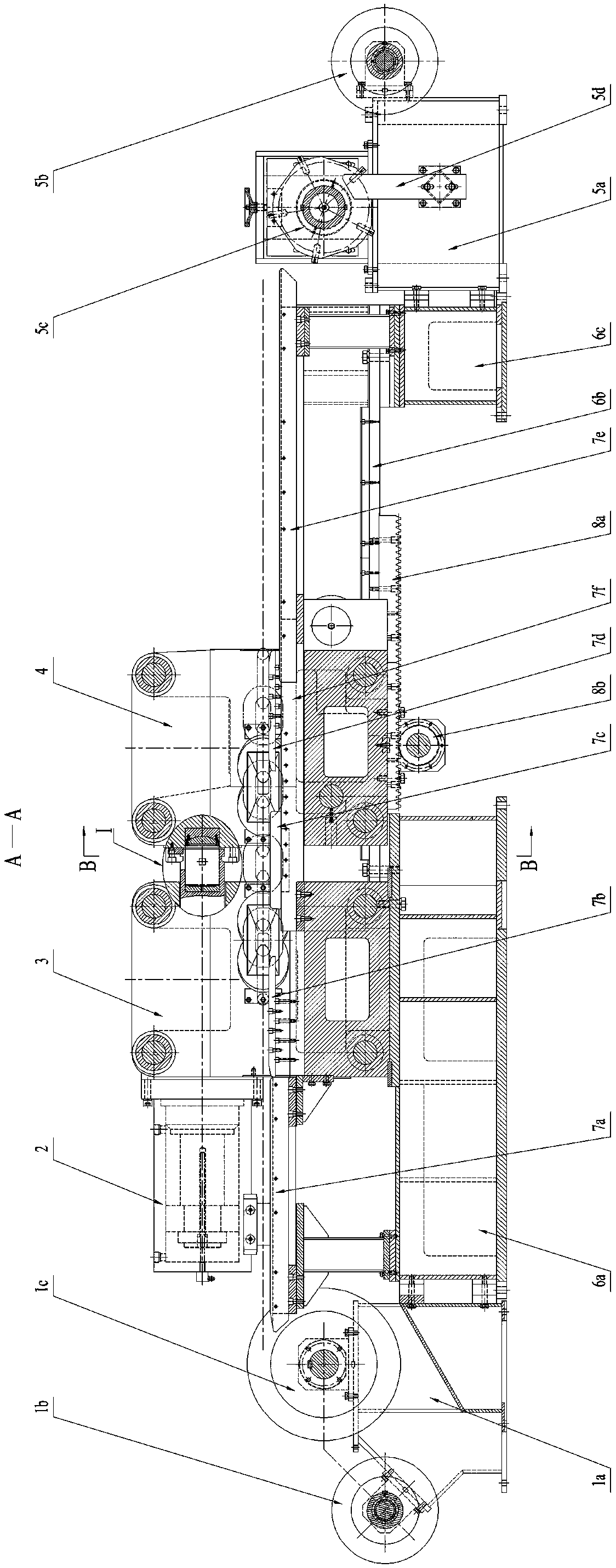

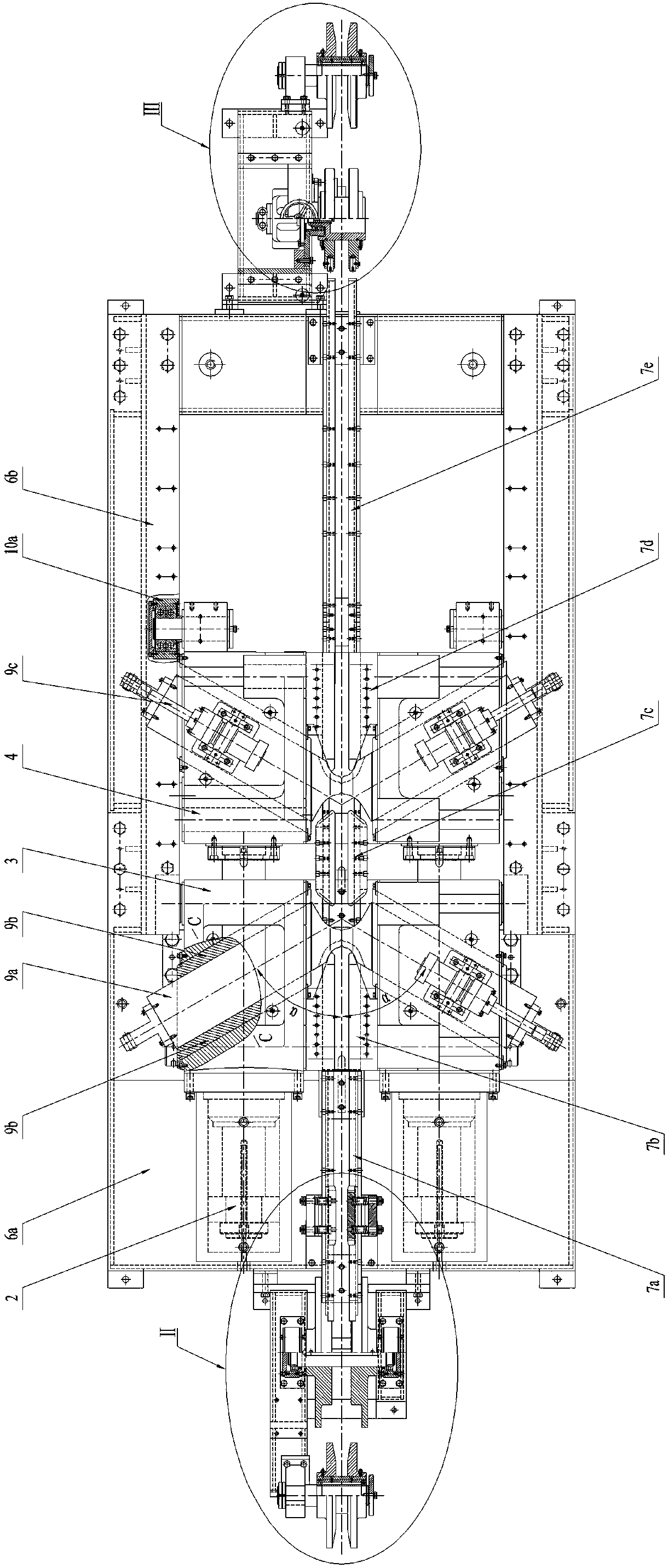

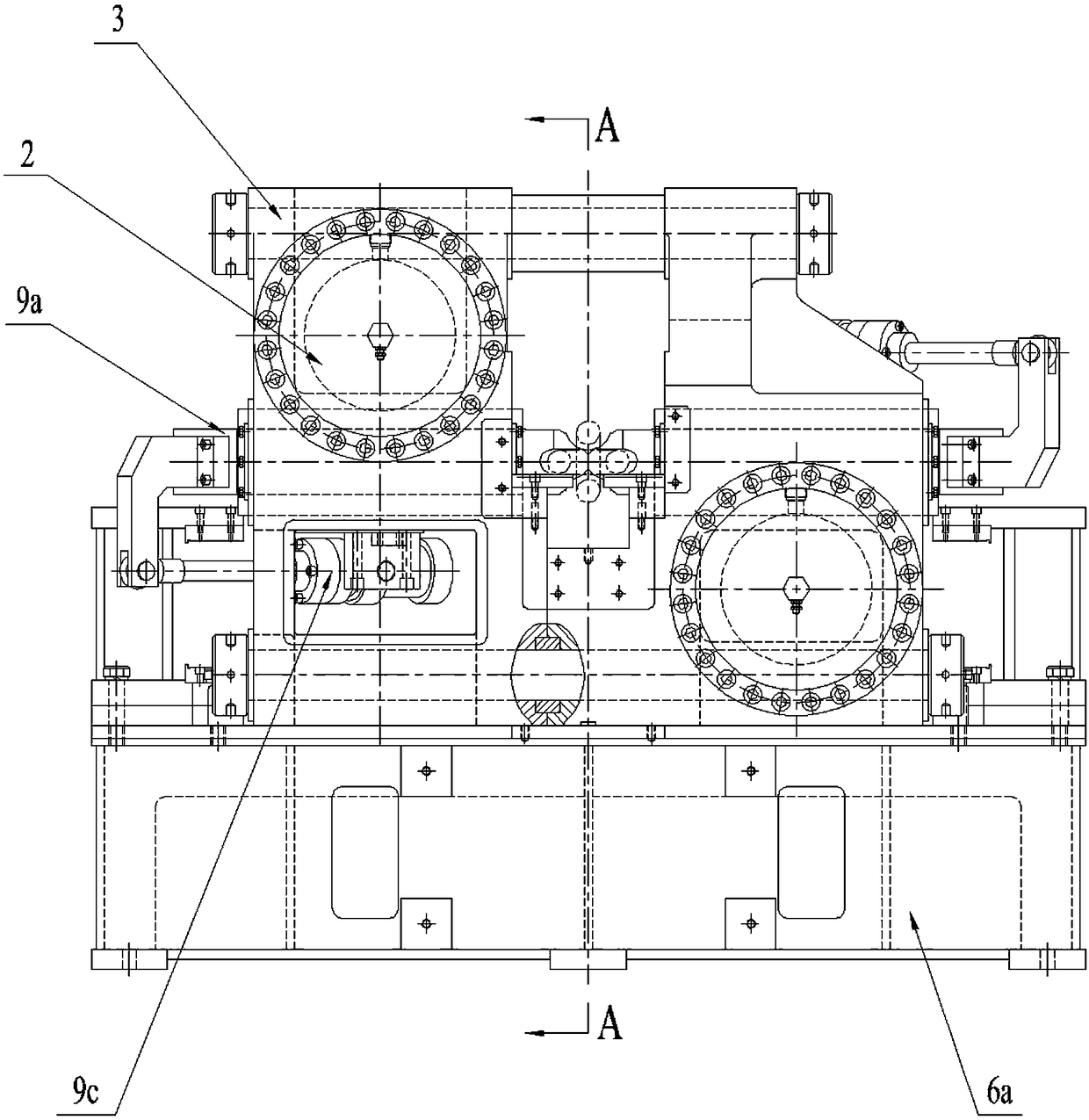

[0047] from Figure 1 to Figure 9 It can be seen that the technical solution of the present invention is: including a frame, a guide rail assembly, a chain guide part, a chain drive part, a static machine base 3, a motor base 4, a guiding mechanism, a stretching fixture assembly, a synchronous mechanism, and a damping mechanism;

[0048] The frame includes a main base 6a and a tail base 6c, and the main base 6a and the tail base 6c are connected by two support beams 6b to form a basic structure of the bed.

[0049]The static machine base 3 is fixed on one end of the main base 6a, and the motor base 4 is movably assembled on the two supporting beams 6b of the basic structure of the bed through the guide mechanism; the stretching oil cylinder 2 is fixedly connected outside the static machine base 3 On the end face, the piston rod of the stretching cylinder 2 passes through the static machine base and connects with the end surface of the motor base, and pushes the motor base so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com